In the evolving landscape of rubber technology, the quest for eco-efficient solutions drives innovation. SanZen Group’s EG22 filler enhancer stands at the forefront, offering a bio-based breakthrough designed to optimize rubber compounds while reducing environmental impact. As leading bio-based filler enhancer manufacturers in China, SanZen combines cutting-edge R&D with sustainability, positioning itself among the top bio-based filler enhancer suppliers in China for global industries.

Technical Advantages of EG22 Filler Enhancer

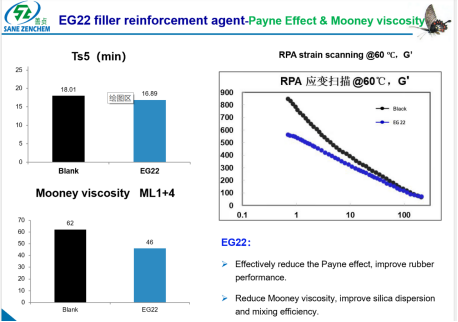

EG22 is engineered to enhance silanization in high-filler rubber systems, particularly those with silica. Its unique molecular structure improves filler dispersion and compatibility, directly addressing the Payne Effect—a critical challenge in rubber science where filler aggregation causes energy dissipation and performance inconsistencies. By reducing filler agglomeration, EG22:

- Boosts Mixing Efficiency: Cuts mixing cycles by 20% and lowers Mooney viscosity, enhancing flowability and processing.

- Optimizes Dynamic Performance: Reduces the Payne Effect by 30%, improving rolling resistance (14% reduction) and wet grip (11% increase) in PCR tires.

- Extends Tire Lifespan: Post-aging tests show a 10% increase in tear strength retention and minimal compression heat generation under constant strain.

Maintains Physical Integrity: Improves tensile strength without compromising abrasion resistance (Lamborn abrasion tests confirm negligible impact).

Eco-Efficiency Meets Customization

Derived from renewable resources, EG22 reduces tire rolling resistance and associated CO₂ emissions, aligning with global decarbonization goals. SanZen offers customized bio-based filler enhancer solutions, tailoring dosages (2-8 phr) to specific process needs—whether optimizing vulcanization curves (160°C × 60min) or fine-tuning dynamic mechanical properties (DMA tests: -80°C to 100°C).

Data-Driven Validation

- Payne Effect & Mooney Viscosity: RPA strain scanning (60°C) confirms superior filler network formation.

- Aging Performance: After 100°C × 48h aging, EG22 compounds exhibit higher retention rates.

- Heat Management: Reduces compression heat generation under constant strain (3.0mm), critical for tire durability.

Why SanZen?

As pioneers in sustainable rubber solutions, SanZen Group leverages EG22 to redefine industry standards. Our technical support spans from lab-scale formulations to industrial-scale integration, backed by rigorous DMA testing and dedicated R&D. For collaborations, visit Sanezen’s official website (www.sanezenrubber.com)

Keywords: Filler enhancer,Bio-based filler enhancer Manufacturers China,Bio-based filler enhancer Suppliers China,Customized Bio-based filler enhancer