In the fast-evolving rubber and plastics industry, ColorRubber NC55 stands out as a revolutionary eco friendly tire sidewall material designed for tire sidewall markings. Developed by SANEZEN Group, a global leader in green technology and smart manufacturing, NC55 combines superior durability, weather resistance, and environmental compliance to meet the stringent demands of modern sustainable tire manufacturing materials.

This article delves into the key features, applications, and technical specifications of ColorRubber NC55, showcasing why it is the preferred choice for high-visibility, long-lasting scratch resistant rubber for tires and UV resistant tire rubber compound solutions.

Why Choose ColorRubber NC55?

1. Exceptional Durability & Scratch Resistance

ColorRubber NC55 is engineered with a dual-cure system to deliver outstanding mechanical properties, including:

- Abrasion resistance — Withstands friction and wear from road conditions.

- Scratch resistance — Maintains surface integrity under harsh environments, making it ideal for scratch resistant rubber for tires.

- Weather & UV resistance — Prevents fading and degradation under prolonged sun exposure, a hallmark of UV resistant tire rubber compound.

2. High Rubber Content for Superior Performance

- Based on white natural rubber (NR), NC55 ensures excellent elasticity and tensile strength.

- Optimized curing properties (TC30: 305 sec, TC90: 622 sec) ensure stable processing and consistent quality, meeting the needs of full range of rubber compound manufacturers .

3. Anti-Aging & Longevity

- Resists discoloration and degradation even under high-temperature sunlight exposure.

- Mooney viscosity (39.6 ML) ensures smooth processing with secure scorch time (T5: 19.42 min), a critical feature for sustainable tire manufacturing materials.

4. Eco-Compliance & Sustainability

- Meets RoHS & REACH environmental standards.

- Supports green manufacturing initiatives with low-carbon production processes, aligning with global demand for eco friendly tire sidewall material.

Technical Specifications

| Property | Specification | Typical Value | Test Method |

| Curing Condition | 160°C × 30min | — | — |

| TC30 (Sec) | 250-380 | 305 | ASTM D5289 |

| TC90 (Sec) | 600-780 | 622 | ASTM D5289 |

| ML (lb-in) | 1.0-2.3 | 1.46 | ASTM D5289 |

| MH (lb-in) | 7.5-9.5 | 8.05 | ASTM D5289 |

| Hardness (Shore A) | 55 ± 3 | 54 | ASTM D2240 |

| Modulus 300% (MPa) | 3-5 | 3.21 | ASTM D412 |

| Tensile Strength (MPa) | ≥12 | 13.58 | ASTM D412 |

| Elongation (%) | ≥550 | 721 | ASTM D412 |

| Specific Gravity (g/cm³) | 1.27-1.33 | 1.318 | ASTM D297 |

| Mooney ML (1+4) @125°C | 37-45 | 39.6 | ASTM D6204 |

| Scorch T5 (min) @125°C | 16-26 | 19.42 | ASTM D6204 |

Applications of ColorRubber NC55

1. Tire Sidewall Markings

- Co-extruded with black NR sidewall compounds for high-visibility branding.

- Applied to sidewall groove patterns for enhanced durability and aesthetics, meeting the demands of full range of rubber compound factory production.

2. Industrial & Automotive Rubber Components

- Suitable for weather-resistant seals, gaskets, and protective coatings.

- Ideal for high-performance rubber parts requiring UV resistant tire rubber compound and scratch resistant rubber for tires.

SANEZEN Group: Your Trusted Partner for Rubber Solutions

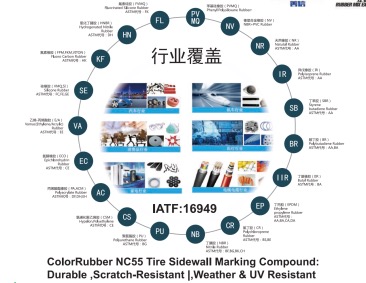

As a global leader in rubber compounding, SANEZEN Group combines 150,000+ metric tons of production capacity with 10,000+ validated rubber compound recipes to deliver cutting-edge solutions. Our expertise ensures we meet the needs of full range of rubber compound suppliers, and factories worldwide.

Why Partner with SANEZEN?

✔ 26+ dedicated rubber compounding lines for specialized production.

✔ 33+ rubber types covered in full-range formulations.

✔ 20+ years of R&D expertise in high-performance rubber compounds.

✔ Independent colored rubber compounding factory for customized needs, including eco friendly tire sidewall material.

Conclusion: The Future of Tire Markings is Here

ColorRubber NC55 redefines durability and sustainability in tire sidewall marking compound applications. With superior abrasion resistance, UV stability, and eco-compliance, it ensures long-lasting performance while supporting green manufacturing initiatives.

For tire manufacturers seeking high visibility, scratch resistant, and environmentally friendly rubber solutions, NC55 is the ultimate choice.

Join the Green Revolution. Redefine the Future with SANEZEN.

About SANEZEN Group

SANZEN Group’s rubber compounding factory, stands as a leading green and smart manufacturing hub in the rubber industry. Leveraging robust technical expertise and decades of experience, we boast a total annual capacity of 150,000+ metric tons and 10,000+ validated compound recipes. Equipped with 26 dedicated production lines covering 33+ rubber types, our facility integrates eco-friendly processes to deliver high-performance solutions with exceptional abrasion resistance, weatherproofing, and anti-aging properties. Our independent colored rubber compounding factory further underscores innovation and quality, solidifying our commitment to being a trusted global partner.

Call to Action

Interested in ColorRubber NC55 for your tire sidewall marking compound or other rubber product applications?

Contact SANEZEN Group today for a customized solution!

Visit our website www.sanezenrubber.com for more innovative rubber compound technologies.