Introduction to HNBR Compound

- NBR undergoes hydrogenation to saturate the double bonds in its polybutadiene segments, resulting in high-performance HNBR compound. The development of HNBR rubber compound aims to enhance NBR’s oil and weather resistance.

- Since the patent publication by Bayer in 1977, commercial production was initiated by Japan’s Zeon Corporation in 1984.

- With the advancement of the automotive and petroleum industries, rubber components require not only oil resistance but also excellent heat resistance, high-temperature and high-pressure resistance, ozone resistance, and wear resistance. Ordinary NBR can no longer meet these demands, prompting the development of HNBR compound to fulfill these requirements.

Properties of HNBR Rubber Compound

- Retains nitrile groups, providing excellent oil and chemical resistance.

- Hydrogenation of butadiene chains imparts superior heat resistance, weather resistance, and chemical stability, enhancing rubber elasticity.

- A small amount of unsaturated double bonds remain for vulcanization, improving cold resistance and compression set.

Performance Characteristics of HNBR Compound

- The saturated structure offers excellent elasticity, heat resistance, oxidation resistance, and low-temperature flexibility.

- HNBR compound with 95% hydrogenation exhibits superior heat-aging resistance, higher tensile strength than NBR, and excellent wear resistance.

Applications and Advantages of HNBR Rubber Compound

- Excellent oil resistance against fuels, lubricants, and aromatic solvents.

- Highly saturated structure ensures superior heat resistance, chemical corrosion resistance, ozone resistance, and compression set performance.

- Additional benefits include high tensile strength, tear resistance, and wear resistance.

Formulation Design Principles of HNBR Compound

1. Selection of Raw Rubber

- Choose appropriate HNBR compound grades based on application needs. Higher acrylonitrile content improves oil resistance, while fully hydrogenated HNBR rubber compound offers better aging resistance.

2. Vulcanization System

- Peroxide vulcanization provides better heat resistance and lower compression set. For customized HNBR compound, optimized curing systems ensure superior performance.

3. Reinforcement System

- Carbon black or inorganic fillers enhance mechanical properties. HNBR compound suppliers often recommend spray carbon black for lower compression set.

4. Plasticizing System

- Specialized plasticizers improve low-temperature performance and oil resistance. HNBR compound manufacturers use high-boiling-point plasticizers for harsh environments.

5. Other Additives

- Dual-component anti-aging systems (e.g., RD/MB) enhance heat resistance. HNBR compound factory formulations may include metal oxides for improved corrosion resistance.

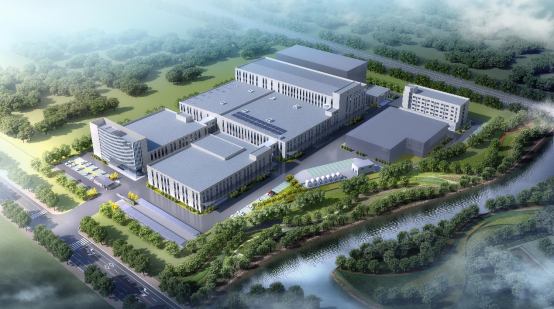

About SaneZen Group’s Lixin Factory – Leading HNBR Compound Suppliers China

As a professional rubber compound factory, we specialize in high-quality HNBR compound manufacturing, offering customized HNBR compound solutions for global rubber product enterprises. Our full range of rubber compound products includes advanced formulations for diverse industrial needs.

See this video to get to know about our factory :

HNBRXX Series – Premium HNBR Rubber Compound Grades

- HNBR45 (Mooney 40): Balanced processing & performance.

- HNBR55 (Mooney 48): Enhanced processing & durability.

- HNBR65 (Mooney 56): Superior heat & oil resistance.

- HNBR75 (Mooney 67): Extreme chemical & heat resistance.

- HNBR85 (Mooney 72): Highest-grade resistance for severe conditions.

Click here to see more detail physical properties about HNBR rubber compound : https://sanezenrubber.com/wp-content/uploads/2025/08/TDS-LX-HNBRXX-CMB-EN-V2-PDF.pd

Why Choose Our HNBR Compound?

✔ Rapid calendering & extrusion

✔ Excellent ozone & weather resistance

✔ Superior grease & solvent resistance

✔ Outstanding heat & low-temperature performance

✔ High wear resistance & mechanical strength

Contact Us – Trusted HNBR Compound Manufacturers China

For customized full range of rubber compound, partner with a leading HNBR compound supplier in China.

Email: yorichen@sanezen.com

WhatsApp: +86-13671641995

Website: www.sanezenrubber.com