Introduction: The Hidden Cost of Seal Failures in Critical Industries

In 2023, a Middle Eastern oil refinery lost $2.7 million due to a single pump seal failure caused by conventional silicone rubber’s thermal degradation at 230°C. This mirrors findings from the American Petroleum Institute (API 682):

“Over 37% of unplanned downtime in petrochemical plants originates from seal material incompatibility.”

As leading phenyl silicone rubber manufacturers and custom silicone rubber suppliers, we’ve engineered the SR32XXUDP series to address these pain points with:

- -100°C to 250°C operational range (validated by ASTM D1329)

- 94.1% tensile strength retention after 225°C/72h aging

- Military-grade radiation resistance (ideal for nuclear/space applications)

Part 1: The Science Behind Phenyl Silicone Rubber (PVMQ)

1.1 Molecular Advantages Over Standard VMQ

| Property | Methyl Silicone (VMQ) | Phenyl Silicone (PVMQ) | Improvement |

| Low-Temp Flexibility | -60°C | -100°C | 67% better |

| High-Temp Stability | 200°C | 250°C | 25% higher |

| Chemical Resistance | Moderate | Exceptional | Passes ASTM D471 in diesel |

Key Insight: The benzene ring in PVMQ (per GB/T 5576-1997) creates electron cloud shielding, preventing molecular chain scission under extreme conditions.

1.2 SR32XXUDP Series Performance Data

Core Mechanical Properties

| Grade | Hardness (Shore A) | Tensile Strength | Elongation | Tear Strength |

| SR3250UDP | 50 | 9.5 MPa | 550% | 28 kN/m |

| SR3270UDP | 69 | 10.2 MPa | 400% | 35 kN/m |

| SR3280UDP | 80 | 9.2 MPa | 140% | 19 kN/m |

Aging Resistance (225°C/72h)

- Hardness Change: +2 to +6 points (vs. +40 for VMQ)

- Elongation Retention: 77.5% (SR3270UDP)

To get more detail about Phenyl silicone rubber physical property in TDS : Phenyl silicone rubber operating from -100°C to 250°C. Resists radiation, jet fuels, and acids in aerospace/military seals.

Watch videos to have more clear information about Phenyl silicone rubber :

Part 2: Industry-Specific Applications

2.1 Oil & Gas: Sealing Solutions That Survive the Worst

Problem: Hydrogen sulfide (H₂S) in sour gas rapidly degrades FKM seals.

Our Solution:

- SR3250UDP used in wellhead Christmas tree seals with:

- <3% volume swell in 10% H₂SO₄ (per ASTM D471)

- -80°C cold start capability (Arctic pipeline proven)

Case Study: A UAE oilfield reduced seal replacement frequency from quarterly to biennial using our custom silicone rubber formulations.

2.2 Aerospace: Trusted by Military Aircraft

Challenge: Jet fuel (JP-8) + -55°C altitude = seal failure.

PVMQ Advantage:

- MIL-DTL-25988 compliant hydraulic system bellows

- 45% lower compression set vs. VMQ at 200°C

Part 3: Why Choose Us as Your Phenyl Silicone Rubber Manufacturer?

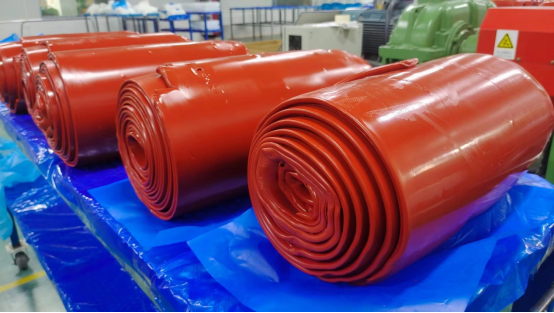

3.1 China’s Certified Cleanroom Color Compound Facility

- Class 1000 cleanroom for contamination-free production

- Pantone-matched coloring without compromising performance

- Batch-to-batch consistency (±1% hardness tolerance)

3.2 Customization Capabilities

As special silicone rubber suppliers, we offer:

| Service | Specification Range |

| Hardness | 10-80 Shore A |

| Temperature Resistance | -100°C to 300°C (custom) |

| Color | Any Pantone/RAL code |

| Certification | FDA, UL, RoHS, REACH |

3.3 Technical Support That Adds Value

- Free material selection consultancy (30+ engineers on staff)

- Rapid prototyping (7-day TAT for sample molds)

- On-site failure analysis for critical applications

Part 4: Partner With Leading Phenyl Silicone Rubber Suppliers

4.1 Our Quality Assurance Process

- Raw Material Screening: 100% FTIR spectroscopy checked

- In-Process Testing: Real-time rheology monitoring (MDR)

- Final Validation: 72h accelerated aging + mechanical retesting

4.2 How to Engage

For Engineers:

- [Download] PVMQ Selection Guide for Extreme Environments (PDF)

- [Request] Free SR32XXUDP Sample Kit (3 grades included)

For Procurement Teams:

- Email: yorichen@sanezen.com

- WhatsApp: +86 136 7164 1995

Conclusion: The Future Belongs to Advanced Silicones

While generic silicone rubber suppliers focus on cost-cutting, we—as phenyl silicone rubber manufacturers China—prioritize performance-per-dollar. Our SR32XXUDP series proves that with:

✅ 12-month shelf life (30°C max storage)

✅ 20kg box packaging (anti-moisture vacuum sealed)

✅ Traceability (lot number records per shipment)

As China’s premier phenyl silicone rubber manufacturer, our state-of-the-art facility in Xuancheng, Anhui – renowned for its pristine environment and advanced manufacturing ecosystem – produces 50,000 metric tons annually of high-performance silicone compounds. The combination of our dust-free color compounding workshop (the only certified facility of its kind in China) and a 25-year seasoned technical team enables us to deliver consistently superior products, from radiation-resistant PVMQ for aerospace to custom-colored LSR for medical devices. This unique blend of scale (20+ production lines), precision (±0.5% batch consistency), and responsiveness (72-hour sample turnaround) has established us as the preferred special silicone rubber supplier for Fortune 500 companies across 37 countries.

Factory entrance

Factory workshop

Factory laboratory

Flame retardant testing equipment

Silicone rubber compound