In an era where high performance, versatility, and sustainable development are equally paramount, industries from rubber to food additives demand more from functional materials than ever before. SaneZen Chem (Shanghai) Co., Ltd., along with its subsidiary Shanghai Powerflex New Material Co., Ltd., is deeply rooted in the materials sector. As leading Precipitated silica Manufacturers and Precipitated silica Suppliers, we leverage our advanced Precipitated Silica technology platform—GreenThinking®—to provide global customers with innovative, high-performance, high-value, and reliable solutions.

Core Value and Technological Edge: Professionalism, Dedication, and Creating Win-Win Outcomes

SaneZen Chem’s core philosophy is “Enterprising, Efficient, Win-Win.” We are not merely a material supplier but a strategic partner supporting our customers on their journey from material selection to formulation optimization. With profound technical expertise and professional production capabilities from our Precipitated silica Factory, we deeply understand the challenges at various application stages.

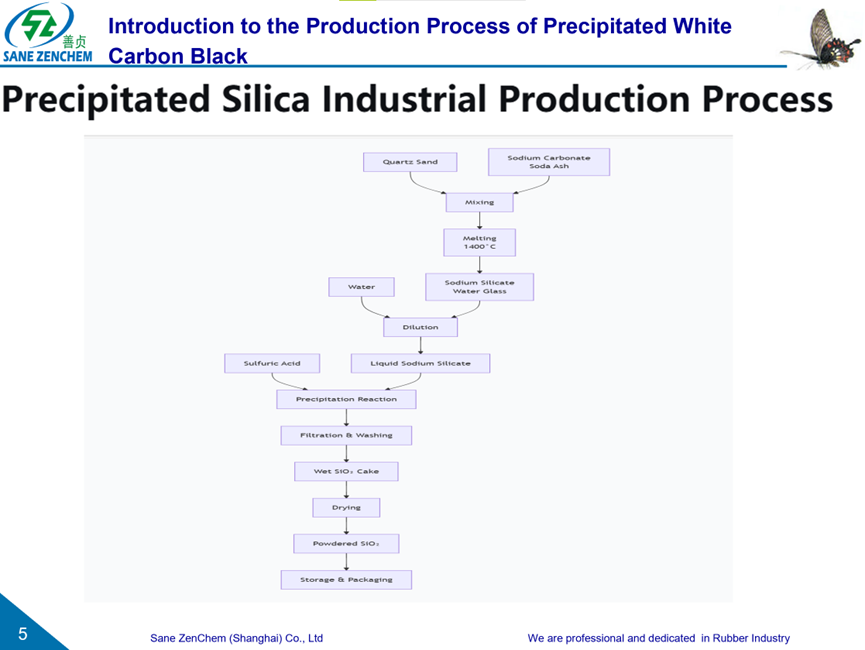

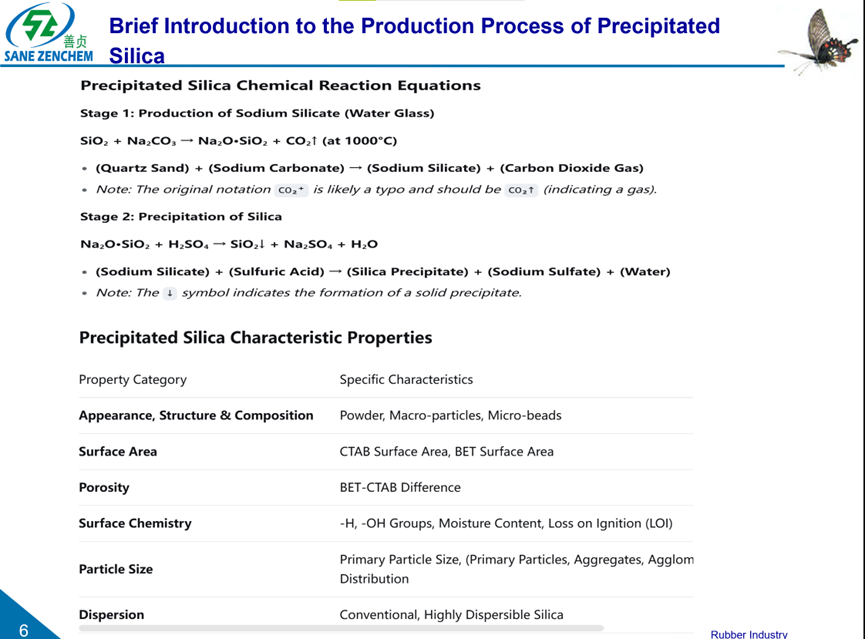

Our technological advantage lies in our precise control over the Precipitated silica manufacturing process. Through stringent process control and surface treatment technologies, we produce a range of high-performance products with specific particle sizes, pore structures, and surface activities to meet the stringent requirements of diverse applications. As one of the professional Precipitated silica Manufacturers China, our production process ensures top quality.

GreenThinking® PPT Series Precipitated Silica Product Portfolio

Our product line is designed to meet the multidimensional needs of various industries.

1. General Purpose High Reinforcement: PT702

This Rubber Silica product is designed for rubber products pursuing outstanding mechanical properties. It significantly enhances tensile strength, tear resistance, and elasticity. Its reinforcement effect is comparable to leading international brands, making it ideal for manufacturing high-strength sports equipment, rubber gaskets, and miscellaneous parts.

- Advantages: Excellent mechanical strength, high tensile strength, good elasticity.

- Applications: Sports goods, rubber gaskets, miscellaneous parts, etc.

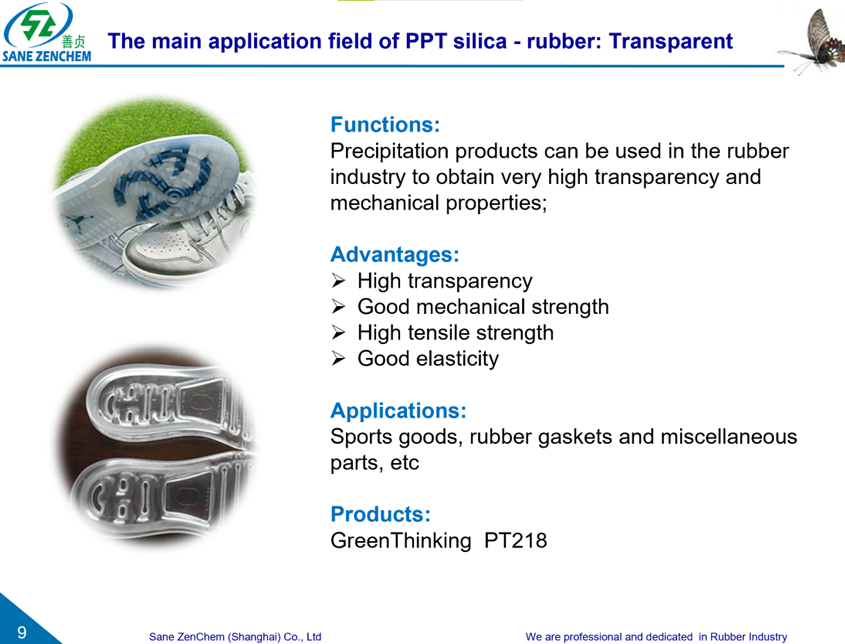

2. High Transparency Application: PT218

For high-end rubber products that require both high transparency and good mechanical properties, PT218 is the optimal choice. This High Transparency Silica perfectly balances transparency and reinforcement, resulting in products that are crystal clear, durable, and elastic. It is specifically formulated as high transparency silica for rubber and excels as silica for transparent shoe soles.

- Advantages: High transparency, good mechanical strength, high tensile strength, good elasticity.

- Applications: Transparent shoe soles, high-end sporting goods, transparent sealing gaskets, etc.

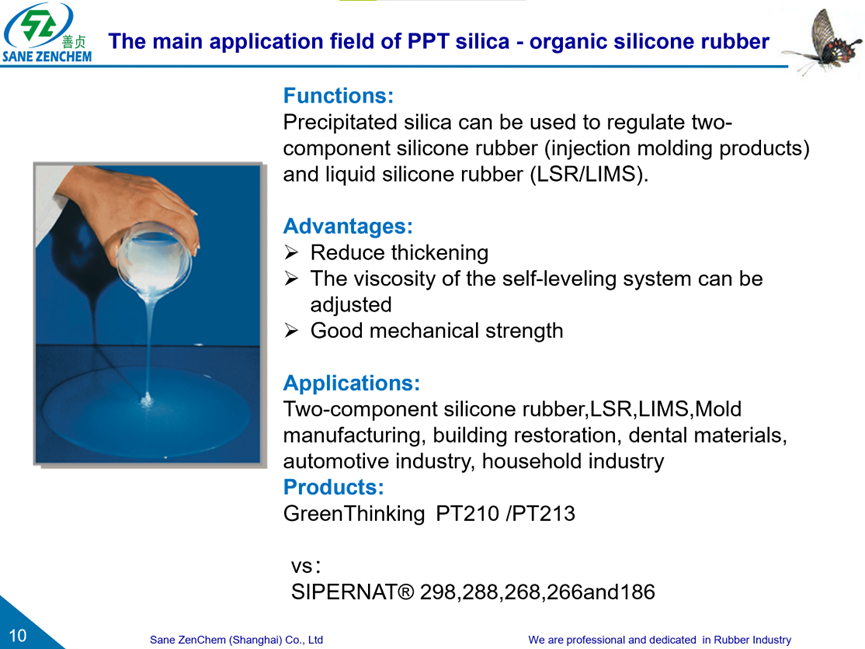

3. Specialty for Silicone Rubber: PT210 / PT213

These products are specialized Silicone Rubber Filler developed for the silicone rubber industry. They represent our expertise in providing precipitated silica for silicone rubber that effectively adjusts the rheological properties of two-component silicone rubber (RTV-2) and liquid silicone rubber (LSR), providing good reinforcement while avoiding excessive thickening, ensuring good processability and flowability.

- Advantages: Adjusts viscosity, reduces thickening, good mechanical strength, high tensile strength, high transparency (PT213), biocompatibility.

- Applications: Mold manufacturing, building restoration, dental materials, automotive industry, household industry, medical products, etc.

4. Beyond Rubber: Applications in Food Additives

Our Precipitated silica products find applications beyond the rubber industry. Thanks to high purity and excellent physicochemical properties, they are widely used as carriers, glidants/anti-caking agents, spray-drying process aids, and grinding aids in fields like food additives, demonstrating the versatility and high safety standards of our products.

Complete Supply Chain & Support System

We provide not only high-quality products but also reliable supply chain support. As dedicated Precipitated silica Suppliers China, we offer various modern packaging solutions and flexible logistics options to ensure the safe and efficient delivery of products to customers worldwide. We specialize in Customized Precipitated silica solutions tailored to specific customer requirements.

Why Choose SaneZen Chem?

- Professional & Dedicated: We are wholeheartedly committed to the rubber and related industries, with a deep understanding of materials and applications.

- Technical Benchmarking: Our products perform on par with industry benchmark brands, offering customers high-quality, cost-effective alternatives.

- Customization & Technical Support: With strong R&D capabilities and deep process understanding, we provide professional technical support and配方优化 services.

- Quality Stability & Reliable Supply: Advanced process control and large production capacity ensure product quality stability and continuous supply.

- Broad Application Coverage: Products cover various fields including rubber reinforcement, transparent products, silicone rubber, and food additives.

SaneZen Chem is not just a supplier of quality products but also your trusted technical partner. We look forward to cooperating with you to explore more possibilities of materials and achieve “Better Together“ through innovative technology.

More information please visit our website: www.sanezenrubber.com