With the rapid advancement of new energy vehicles, 5G communication, and high-end consumer electronics, the requirements for the flame retardancy, environmental safety, and long-term reliability of key component materials have reached unprecedented levels. The UL94 V0 standard has become the baseline for flame retardant materials. However, merely passing V0 certification is far from the end goal. This article, using the Sanesil SR64XX UFR series of halogen-free Flame Retardant Silicone Rubber as a case study, delves into the selection philosophy Beyond V0. It analyzes how to comprehensively choose high-performance silicone rubber compound truly suited for next-generation electronic and electrical equipment, based on multiple dimensions including thermal aging performance, mechanical stability, environmental regulations, and processing technology. For specialized production, partnering with a reliable silicone rubber compound Factory or a supplier offering Customized silicone rubber compound is essential.

I. Introduction: Why is UL94 V0 the Baseline, Not the Finish Line?

In the safety design of electrical and electronic products, preventing fire spread is paramount. UL 94 (Underwriters Laboratories Standard for Safety for Flammability of Plastic Materials for Parts in Devices and Appliances) is the internationally most widely recognized standard for assessing the flammability of polymeric materials. Among its ratings, V0 represents the highest level in the vertical burning test, requiring that after two 10-second flame applications, the sample’s flaming combustion time does not exceed 10 seconds, and no burning drips ignite the cotton below. Therefore, selecting a UL94 V0 Silicone rubber compound is a fundamental step for engineers.

However, in today’s context of accelerated technological iteration and increasingly harsh operating environments, significant performance differences lie behind the “V0” label. Some materials, in pursuit of ultimate flame retardancy, may compromise other critical properties, such as:

• Environmental Safety: Use of halogenated flame retardants, which produce toxic and corrosive gases during combustion.

• Long-term Thermal Stability: Rapid aging, cracking, and loss of sealing or protective functions under prolonged high-temperature operation.

• Mechanical Properties: High compression set, leading to seal failure under constant stress; or insufficient tear strength, impacting product lifespan.

This means the modern engineer’s selection criteria must evolve from “Is it V0?” to “What kind of V0 is it?”. Below, we will systematically deconstruct the key selection factors for high-performance Flame Retardant Silicone Rubber using a benchmark product—the Sanesil SR64XX UFR series.

II. Beyond V0: The Four Core Dimensions for Selecting High-Performance Flame Retardant Silicone

Dimension 1: Environmental Safety of the Flame Retardant System — “Halogen-Free” is the Inevitable Trend

Global environmental regulations (e.g., EU RoHS, REACH) and the green supply chain requirements of major end brands are strongly driving material halogen-free initiatives. Halogenated flame retardants are now prohibited in many application fields.

The Sanesil SR64XX UFR Solution:

This series is explicitly labeled “Halogen-free”. Its outstanding flame retardant performance is fundamentally powered by our in-house developed, high-efficiency, halogen-free, and eco-friendly FRseries flame retardant. This FR system employs a unique synergistic mechanism to achieve highly efficient flame inhibition in both the gas and condensed phases without relying on bromine or chlorine. This ensures the material self-extinguishes rapidly upon flame removal. Leveraging this advanced technology, Sanesil SR64XX UFR not only achieves the V0 rating in the most rigorous vertical burn test but also does not release toxic or corrosive brominated/chlorinated gases during combustion, significantly enhancing the overall safety and environmental compliance of the end product. Concurrently, the series complies with the stringent RoHS 2.0 environmental standard.

To gain deeper insights into the technological advancements and trends in halogen-free flame retardants, please refer to: White Paper on Development Trends and Applications of Halogen-Free Eco-Friendly Flame Retardants.

Verifying the “halogen-free” attribute and understanding the core technology behind it is the first step towards green design and achieving product differentiation. This is especially critical for Flame Retardant Silicone for Automotive Industry applications and for sourcing from responsible flame retardant silicone rubber Manufacturers and flame retardant silicone rubber Suppliers, including those based in China (flame retardant silicone rubber Manufacturers China, flame retardant silicone rubber Suppliers China).

Dimension 2: Long-Term Thermal Aging Performance — The “Life Prognosis” of Material at High Temperatures

For applications like Flame Retardant Silicone for EV Battery Seals, cables in motor compartments, and High Temperature Silicone for Charging Piles, materials are often exposed to elevated temperatures continuously. Excellent initial properties do not guarantee reliability over years of service. The retention of properties after thermal aging is the ultimate test of a material’s heat resistance grade, a key consideration for any Silicone Rubber for High Temperature Applications.

Performance Demonstration of Sanesil SR64XX UFR (using SR6450UFR as an example):

Key thermal aging data from its TDS:

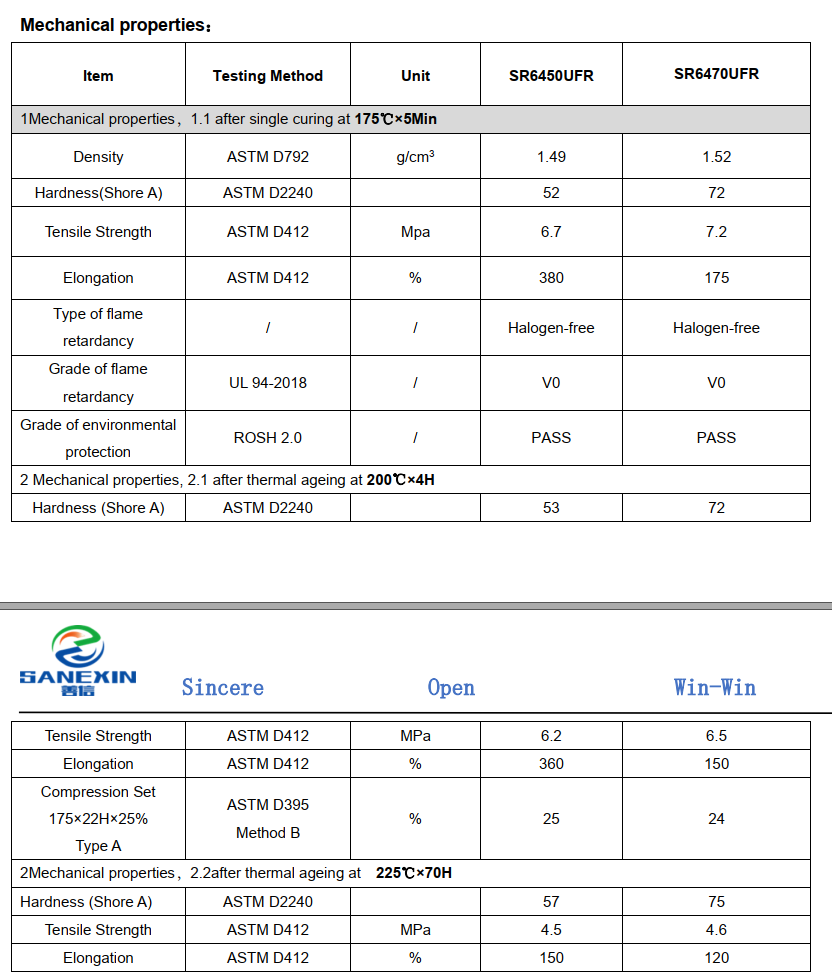

• Initial Properties (after cure @175℃×5min):

o Hardness (Shore A): 52

o Tensile Strength: 6.7 MPa

o Elongation at Break: 380%

• After Thermal Aging @200℃×4 hours:

o Hardness: 53 (Change Rate: +1.9%, exceptionally stable)

o Tensile Strength: 6.2 MPa (Retention: 92.5%)

o Elongation: 360% (Retention: 94.7%)

• After More Severe Aging Conditions (presumably higher temperature or longer duration):

o Hardness: 57

o Tensile Strength: 4.5 MPa

o Elongation: 150%

In-depth Analysis:

After short-term aging at 200°C, SR6450UFR retains over 90% of its mechanical properties with negligible hardness change, indicating exceptional molecular stability at high temperatures. Even under more severe aging conditions, the material maintains considerable tensile strength (4.5 MPa) and flexibility (150% elongation), far from brittle failure or degradation. This superior thermal stability ensures that seals and insulation made from it provide continuous, effective protection throughout the product’s intended service life.

Dimension 3: Low Compression Set — The Cornerstone of Dynamic and Static Sealing

Compression set is a core indicator measuring an elastomer’s ability to recover its original shape after prolonged compression. A lower value signifies better elastic recovery and more durable sealing performance.

Performance Demonstration of Sanesil SR64XX UFR:

Under the demanding test condition of 175℃×22 hours×25% compression (ASTM D395 Method B):

• Compression Set of SR6450UFR: 25%

• Compression Set of SR6470UFR: 24%

Industry Comparison & Value:

For conventional silicone rubbers, compression set under such high temperature and duration often exceeds 40% or even 50%. The SR64XX UFR series achieves a remarkably low value around 25%, placing it at the industry forefront. This translates to:

- Longer-lasting Sealing Force: When used in battery cover gaskets or O-rings, it maintains a tight seal against moisture and dust ingress, even through thermal cycles and constant vibration.

- Reduced Stress Relaxation: As a gasket for vibration damping, it provides consistent support force over time, preventing connection loosening and noise caused by stress relaxation.

Dimension 4: Process Compatibility & Comprehensive Mechanical Properties — Ensuring Manufacturability and Reliability

A good material must be manufacturable and processable, a strength of a proficient silicone rubber compound Factory.

• Extrusion Performance: The TDS explicitly states “good extrusion performance,” crucial for the continuous, efficient production of wire jackets and custom profiles.

• Hardness Options: Availability of SR6450UFR (Shore A 52) and SR6470UFR (Shore A 72) covers diverse needs from soft sealing to rigid protection.

• Strength-Elongation Balance: SR6450UFR offers a high tensile strength of 6.7 MPa and an elongation at break of 380% while maintaining a low 52 Shore A hardness, demonstrating excellent toughness for applications requiring flexing and dynamic sealing, such as Flame Retardant Silicone for Wearable Devices.

III. Cutting-Edge Application Scenarios: How SR64XX UFR Empowers Future Technology

Scenario 1: New Energy Vehicle Powertrain Battery Systems

• Pain Points: Battery packs require high ingress protection (IP67/IP68) to prevent internal short circuits. Materials need to be flame retardant (preferably V0), halogen-free (to prevent toxic gas during thermal runaway), resistant to long-term heat (battery operating temps ~80-90°C, locally higher), and exhibit low compression set.

• Solution: Using this UL94 V0 Certified Silicone Rubber compound for large planar gaskets between the battery cover and tray. Its low compression set ensures sealing integrity throughout the vehicle’s life; halogen-free V0 rating provides a “double safety” layer; superior thermal aging performance copes with the pack’s internal heat environment. This makes it an ideal Flame Retardant Silicone for EV Battery Seals.

Scenario 2: 5G Communication Base Stations & High-Speed Connectors

• Pain Points: High power density in 5G AAUs leads to significant internal heat. Miniaturized high-speed connectors demand higher flame retardancy and heat resistance from insulation materials.

• Solution: Employ SR64XX UFR for insulation and jacketing of internal cables in base stations and as seals for waterproof connectors. Its good extrusion performance suits thin-wall cable extrusion, the V0 rating ensures safety, and heat resistance guarantees long-term performance without degradation in the hot internal environment, fulfilling the role of High Temperature Silicone for Charging Piles and related infrastructure.

Scenario 3: High-End Consumer Electronics & Wearables

• Pain Points: Device miniaturization creates compact spaces where material flame retardancy is mandatory. Environmental sustainability has become a core brand selling point.

• Solution: Can be used for flame retardant insulation layers inside smartwatch straps (Flame Retardant Silicone for Wearable Devices), cushioning pads for pouch cell batteries in smartphones, etc. Its halogen-free nature meets brand green standards, and its ease of pigmentation (“Milky appearance and easy to pigment”) caters to aesthetic color requirements. For such specialized needs, a Customized silicone rubber compound or Customized Flame retardant silicone rubber from experienced flame retardant silicone rubber Manufacturers is often the solution.

IV. Conclusion: Summarizing the Future-Oriented Material Selection Strategy

When selecting a UL94 V0 Certified Silicone Rubber compound, modern engineers should adopt a systematic evaluation framework:

- Confirm Basic Certification: Verify valid UL94 V0 certification from an authoritative third party.

- Check Environmental Compliance: Ensure it is halogen-free and compliant with the latest directives like RoHS.

- Evaluate Long-Term Reliability: Focus on property retention after thermal aging (prioritize long-term data like 200°C×1000h) and compression set at high temperatures.

- Match Application Process: Assess processability (extrusion, molding) based on product form.

- Balance Comprehensive Mechanics: Find the optimal balance of hardness, tensile strength, and elongation for the specific application.

The Sanesil SR64XX UFR series of Flame Retardant Silicone Rubber stands as a prime example fulfilling this selection strategy. It not only meets the baseline safety threshold of UL94 V0 in a halogen-free manner but also, through its exceptional thermal stability, very low compression set, and good processability, provides a future-proof, safe, and reliable material solution for cutting-edge fields like new energy vehicles (Flame Retardant Silicone for Automotive Industry), 5G communication, and high-end electronics. In an era of rapid technological advancement, choosing a material is choosing a commitment to the product’s lifelong performance and safety. Sourcing from reputable flame retardant silicone rubber Manufacturers China or global flame retardant silicone rubber Suppliers who can provide such high-performance, and potentially Customized Flame retardant silicone rubber, is a critical step in the design process.