Introduction: Reliability Tempered in Demanding Conditions

In the field of industrial sealing, the emergence of new materials is often accompanied by market buzz, but only products doubly verified by time and complex operating conditions precipitate into classics trusted by engineers. It is not a novel concept from the laboratory, but a mature choice playing a critical role silently within production lines and at the heart of equipment. The SR2100UOR Series Oil Resistant Silicone Rubber produced by Sanexin Polymer under the SaneZen Group is precisely such a mature product tempered by the market. Over the years, with its stable, reliable, and predictable performance, it has solved a series of sealing pain points caused by insufficient material properties in numerous demanding industrial applications globally. This article aims to provide an in-depth analysis of how this classic High Temperature Silicone rubber and Low Compression Set Silicone rubber, with its comprehensive performance advantages, continues to provide solid support for high-reliability sealing designs.

I. Confronting Enduring Industry Pain Points: Why Does the SR2100UOR Remain Relevant?

Despite continuous advances in industrial technology, some core material challenges persist. The design of the SR2100UOR series aims to address these long-standing issues fundamentally.

1.1 Performance Degradation Under Long-Term Oil Immersion and Thermal Aging

Equipment design life is increasingly longer, meaning sealing materials must maintain function throughout their entire lifecycle. Ordinary Silicone rubber Compound often experiences excessive swelling or hardening and embrittlement after long-term high-temperature oil immersion, leading to seal failure. This unpredictability in performance is a major risk faced by design engineers.

1.2 Compression Set: The Barometer of Long-Term Sealing Efficacy

For equipment designed for “maintenance-free” or long maintenance intervals, compression set is the most critical indicator of seal durability. A high compression set rate means the sealing force decays rapidly over time, forcing companies into frequent preventive maintenance or facing the risk of unexpected downtime. Therefore, finding a true Low compression set silicone rubber for seals becomes crucial.

1.3 The Ultimate Pursuit of Performance Balance and Customizability

Engineers need not one exceptionally outstanding indicator, but all key properties (hardness, strength, oil resistance, compression set) to be at a high level and balanced. Simultaneously, specific requirements for hardness and process in different application scenarios demand that material suppliers provide a trusted product family covering a broad spectrum, particularly excelling in specific processing methods like Silicone rubber for Extrusion.

II. A Classic Piece: In-Depth Re-analysis of SR2100UOR Series Performance

As a mature product, the SR2100UOR series possesses a wealth of repeatedly verified, reproducible performance data. This data forms the reliable design foundation for engineers.

2.1 A Proven Mechanical Performance Spectrum

The SR2100UOR series offers a hardness range from approximately 50 to 80 Shore A, forming a complete product matrix from SR2150UOR to SR2180UOR. Its excellence lies in maintaining outstanding comprehensive mechanical properties across the entire hardness range.

- Balance of Strength and Elasticity: Taking the widely applied SR2170UOR as an example, its tensile strength remains stable above 8.2 MPa, tear strength exceeds 15 kN/m, while maintaining an elongation at break of over 220%. This combination ensures the seal has sufficient resistance to damage and conforms well to the sealing surface, adapting to certain operational fluctuations.

- Performance Stability: Whether after primary or secondary curing, its mechanical parameters change minimally. For instance, the hardness of SR2180UOR increases by only 1 unit after secondary curing, with strength slightly increasing to 8.6 MPa. This stability stems from a mature formulation system and curing process, ensuring batch-to-batch consistency for this high-performance Silicone rubber Compound.

2.2 Excellent Thermal Stability, Ensuring Long Service Life

After 70 hours of aging in 225°C hot air, this High temperature oil resistant silicone rubber compound demonstrates the robustness characteristic of a classic material.

- The tensile strength retention rate for all models exceeds 80%, with a mild change in hardness (+4 to +5 points), indicating its stable siloxane backbone structure and cross-linked network effectively resist thermo-oxidative aging, avoiding rapid material degradation.

2.3 Outstanding Oil Resistance: The Embodiment of Core Value

The “UOR” (Ultimate Oil Resistance) characteristic of SR2100UOR has been fully validated in various oils, with its Silicone rubber ASTM #901 oil resistance being particularly notable.

- In Harsh ASTM #903 Oil: The volume swell rate remains stable within an acceptable range of 34-37%, and sufficient mechanical strength is maintained after swelling (e.g., SR2180UOR tensile strength remains at 6.3 MPa after swelling), ensuring basic sealing function upon accidental exposure to harsh oils.

- In Common ASTM #901 Oil: Its performance is even more outstanding, with the volume change rate strictly controlled at a very low level of 2.3% to 5.4%. This means the seal dimensions remain almost unchanged after long-term immersion in oil, which is key to ensuring long-term sealing reliability. Its high retention of mechanical properties in this environment makes it an ideal choice for manufacturing Hydraulic seal silicone rubber material and Silicone rubber for automotive engine oil seals, representing an economical alternative to higher-cost FKM.

2.4 Extremely Low Compression Set: The Cornerstone of Long-Lasting Seals

Tested at 177°C for 22 hours, the compression set of the SR2100UOR series is all below 11%, with the best value reaching 7.9%. This data, verified through countless tests, is the “ID card” of this classic Low Compression Set Silicone rubber. It directly translates into longer seal life and lower maintenance costs for equipment, providing customers with long-term and quantifiable value.

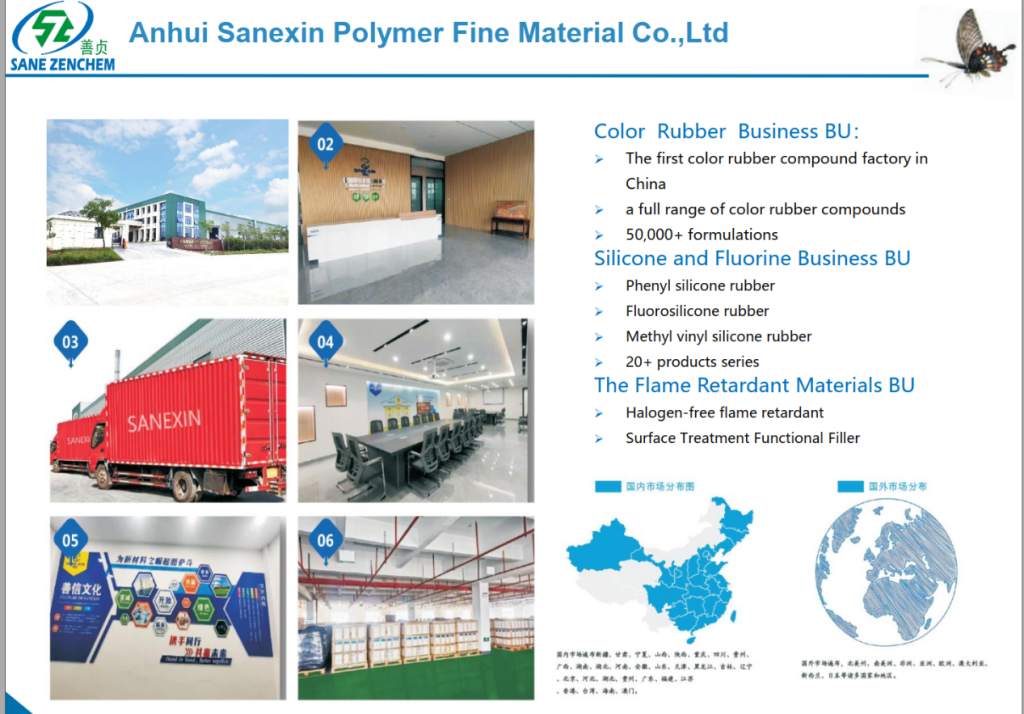

III. Profound Heritage: How Sanexin Polymer Forges Classic Quality

The reliability of a mature product ultimately stems from the profound heritage and rigorous systems of its manufacturer. As a well-known Oil resistant silicone Manufacturers China and Oil resistant silicone Suppliers China, Sanexin Polymer consistently adheres to high standards.

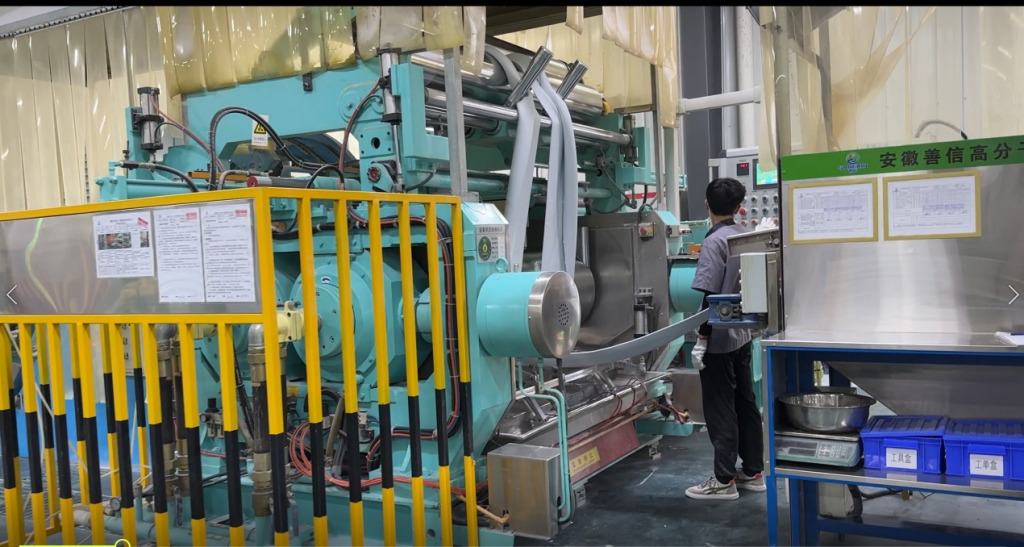

3.1 Unification of Scale and Stability

With its annual production capacity of thousands of tons, Sanexin Polymer ensures ample supply and excellent batch stability for the SR2100UOR series products. For customers seeking reliable Oil resistant silicone Manufacturers and Oil resistant silicone Suppliers, this means no need to revalidate product performance due to batch changes, reducing quality risks and management costs.

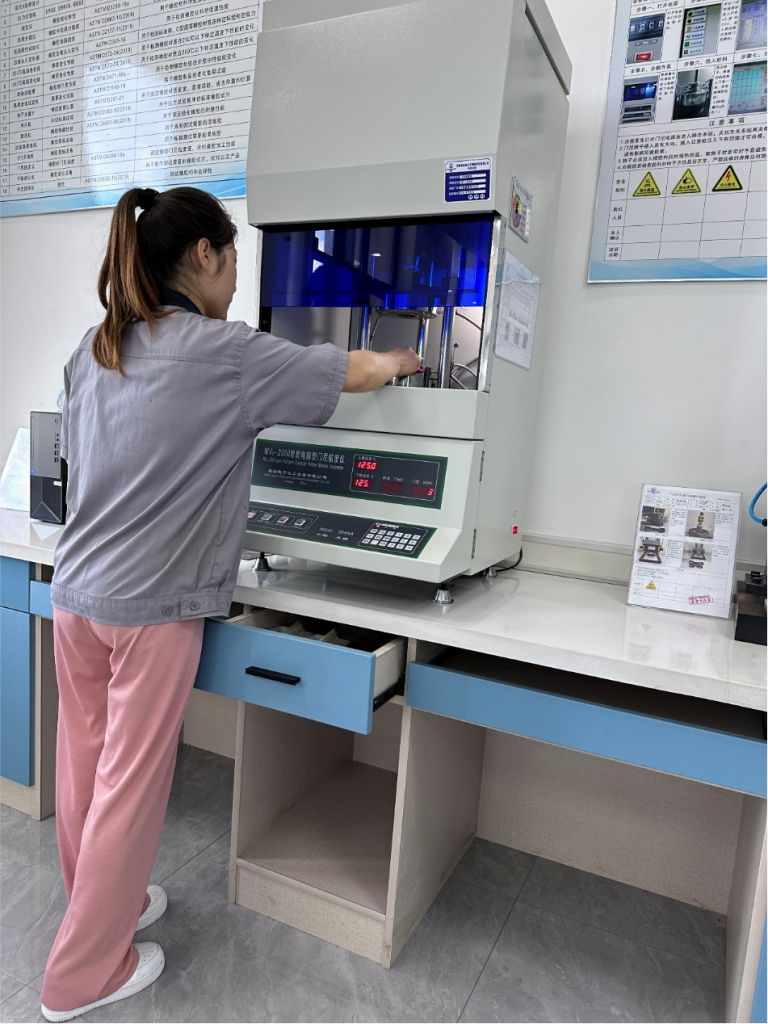

3.2 Class 10,000 Cleanroom: Practicing the Commitment to Consistency

This series is produced in a Class 10,000 cleanroom. This not only guarantees extremely high product cleanliness, avoiding seal failure caused by impurities, but also embodies the precise control of its production process. This extreme requirement for the production environment is the physical guarantee for delivering high-performance, highly consistent Silicone rubber for Extrusion and other molded products.

3.3 Focus on Customization Capabilities

As a mature product, the SR2100UOR series itself is a mature platform. Leveraging the R&D strength of the SaneZen Group, Sanexin Polymer can provide flexible Custom oil resistant silicone rubber compound services on this basis. Whether it’s color matching, adjustment of curing rates, or formula fine-tuning for specific media, professional and rapid response is available.

3.4 Market-Validated Quality System

Behind every technical parameter of the SR2100UOR series is the strict quality management system implemented by Sanexin Polymer. Full-process traceability and rigorous inspection, from raw materials and processes to finished products, ensure the consistent performance data of this product over the years, winning long-term market trust for this top-tier Oil resistant silicone Manufacturers.

IV. Classic Application Scenarios: Wide Versatility of the Solution

Through years of market application, the SR2100UOR series has proven its value in the following fields:

- Automotive Industry: As an excellent Silicone rubber for automotive engine oil seals, it is widely used in engine valve cover gaskets, oil pan seals, turbocharger pipe connection seals, etc., tolerating high-temperature engine oil and engine bay ambient temperature fluctuations.

- Industrial Equipment: Used for seals, O-rings in hydraulic and pneumatic systems, its reliability as a Hydraulic seal silicone rubber material ensures stable performance in standard hydraulic oils like ASTM #901.

- Energy & Heavy Machinery: In oilfield equipment, large generator sets, and other applications requiring long life and low maintenance, its advantage as a Low compression set silicone rubber for seals is fully utilized.

- Specific Consumer Sectors: Suitable for sealing components in household appliances and kitchen equipment that require contact with grease and high temperature resistance, demonstrating its versatility as a multi-functional Oil Resistant Silicone Rubber.

Conclusion: Choosing a Classic is Choosing Reliability and Efficiency

The SR2100UOR series is not a product chasing trends. Its value lies in its time-tested performance stability, excellent comprehensive metrics, and fundamental solving ability for industrial sealing challenges. In a market filled with various new material claims, choosing a fully validated mature High Temperature Silicone rubber and Oil resistant silicone rubber compound like SR2100UOR means lower design risk, faster time-to-market, and more controllable total cost of ownership for engineers. Partnering with a reliable Oil resistant silicone Manufacturers China like Sanexin Polymer further ensures supply chain security.

Sanexin Polymer will continue to use this classic product as a benchmark, adhering to consistent rigorous standards and manufacturing philosophy to serve global industrial customers, providing a solid material foundation for building a more reliable and efficient industrial system.