In today’s industrial materials sector, NBR PVC Rubber Compounds, as high-performance NBR PVC rubber blends, are becoming the preferred choice for industries such as automotive, wires & cables, and petrochemicals due to their exceptional comprehensive properties. With continuously rising global demands on material performance, these compounds have secured a significant market position thanks to their unique NBR PVC Rubber Compound Oil Resistance, abrasion resistance, flame retardancy, and aging resistance. This article delves into the technical characteristics, application scenarios, and market prospects of NBR PVC Rubber Compounds, combining the core strengths of our company – a leading Professional Rubber Compound Manufacturer China with over 20 years of experience – to provide a comprehensive reference for industry users.

1. Market Background and Industry Demand

As industrial automation and environmental requirements increase, the limitations of traditional rubber materials in terms of oil resistance, solvent resistance, and weather resistance are becoming increasingly apparent. NBR PVC rubber blends, by blending Nitrile Butadiene Rubber (NBR) with Polyvinyl Chloride (PVC), effectively combine the elasticity of rubber with the rigidity of plastic. This not only addresses the performance shortcomings of single materials but also expands application boundaries. According to industry data, the global rubber-plastic blends market is growing at an annual rate of over 8%, with NBR PVC Rubber Compounds being one of the fastest-growing segments due to their cost-effectiveness and high performance, driving demand for reliable NBR PVC rubber blends Manufacturers China.

In the automotive manufacturing sector, with the popularization of electric vehicles, requirements for high-temperature resistance, flame retardancy, and anti-static properties of seals, oil pipes, and cable sheaths have significantly increased. This creates excellent opportunities for Custom Rubber compound Manufacturers to develop specialized solutions. In the wire and cable industry, environmental regulations are driving the demand for replacements of low-smoke, zero-halogen materials. Meanwhile, components like industrial conveyor belts and rollers require materials with high wear resistance and long service life. These trends collectively drive the market penetration of NBR PVC Rubber Compounds, making them a key material for technological upgrades.

2. Product Overview and Technical Characteristics

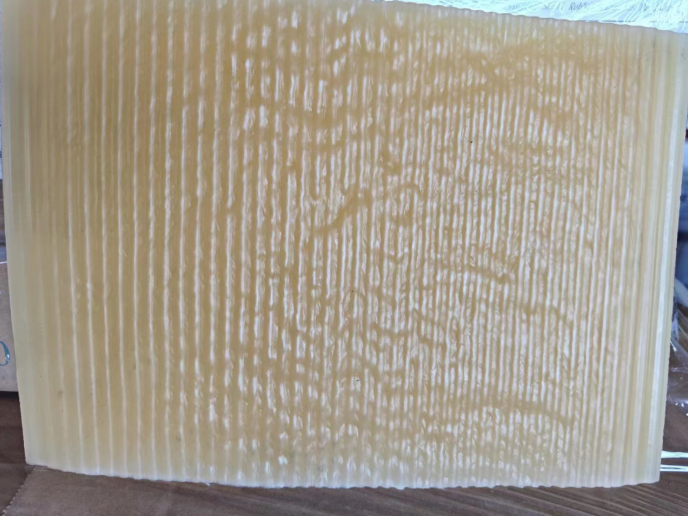

NBR PVC Rubber Compounds are composite materials created through the scientifically proportioned blending of NBR and PVC. Their core advantage lies in the synergistic effect of molecular chains, optimizing performance. As experienced Custom Rubber compound Suppliers China, we offer various models such as NV2355, NV3355A, NV5090, and NV7030, all of which have passed stringent international standard tests (e.g., ASTM) and demonstrated excellent performance in practical applications.

Oil and Solvent Resistance

The outstanding NBR PVC Rubber Compound Oil Resistance is one of their most prominent features. According to TDS data, after immersion in ASTM No. 1 oil for 70 hours, the volume change rate of the product is only -10.24% (NV2355), while after 48 hours in Fuel C, the volume swelling rate is controlled within +38.89%. This indicates that the material can maintain dimensional stability and mechanical strength even in extreme oily environments, making it suitable for critical components like oil pipes and sealing rings.

Mechanical Strength and Abrasion Resistance

The tear strength of the material can reach 14.84 Kg/cm² (NV5090), with an elongation at break as high as 650%, while the M100 modulus remains above 2.35 Kg/cm². This combination of high elasticity and high strength ensures product durability under dynamic loads, making it particularly suitable for high-wear scenarios like conveyor belts, rollers, and shoe soles.

Flame Retardancy and Anti-static Properties

The Flame Retardancy of NBR PVC rubber blends is certified by standards like UL94, with a Limiting Oxygen Index (LOI) that can exceed 28, effectively inhibiting flame spread. Furthermore, the material’s surface resistivity is as low as 10^6-10^8 Ω, possessing Excellent Anti-static Characteristics, making it suitable for explosion-proof environments such as mining and chemical industries.

Weather Resistance and Environmental Advantages

The product shows no cracks in ozone resistance tests (80 pphm, 40°C, 120 hours), and low-temperature retraction tests indicate a brittleness temperature as low as -48°C (NV2355), suitable for frigid climates. Simultaneously, our use of environmentally friendly plasticizers (e.g., DPHP, ATBC) ensures compliance with RoHS and REACH regulations, meeting global green manufacturing needs.

3. Application Fields and Case Studies

The Application Fields of NBR PVC rubber blends cover multiple industrial branches, and their versatility makes them an ideal replacement for traditional rubber and plastic. Here are typical application scenarios:

Automotive Industry: Used for manufacturing fuel hoses, brake hoses, and cable sheaths. For example, the high hardness (65 Shore A) and oil resistance of NV3355A ensure the long-term stable operation of components in the high-temperature, oily environment of the engine compartment.

Wires and Cables: As insulation and sheathing materials, the ozone resistance and flame retardancy of NBR PVC Rubber Compounds effectively enhance cable safety in outdoor and complex environments. Test data for NV7030 in this field shows a volume change rate of only +0.20% in ASTM No. 903 oil, far superior to ordinary PVC.

Industrial Components: Including conveyor belts, seals, and rollers. The high elongation at break (650%) and low compression set (45.34%) of NV5090 make it perform excellently in high-speed transmission systems, extending equipment service life.

Consumer Goods and Footwear: Utilizing the material’s flexibility and slip resistance for producing shoe soles and tool handles. Its surface smoothness also supports rapid extrusion and calendering, improving production efficiency.

4. Company Core Advantages and Technical Support

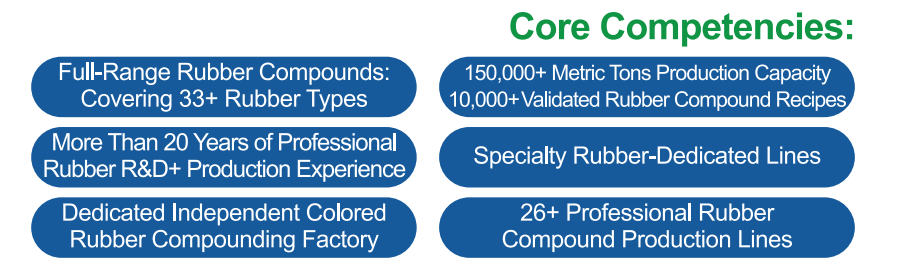

As an enterprise with over 20 years of professional rubber R&D and production experience, our company has accumulated profound expertise as Professional Rubber Compound Manufacturers China. Our core competitiveness is reflected in the following aspects:

Comprehensive Product Portfolio

We are a Full range of rubber compound supplier providing over 33 rubber types of compound solutions, including NBR, EPDM, Silicone Rubber, etc., capable of meeting the Customized rubber compound needs of different industries. For instance, we have developed heat-resistant grade NBR PVC rubber blends for high-temperature environments and dedicated independent production lines for colored compounds to ensure color consistency and stability.

R&D and Production Capabilities

Through 26+ professional rubber compound production lines, we achieve seamless integration from formula design to mass production. The standard formulas in the TDS (e.g., NV7030 using carbon black N774 and DOP plasticizer) are all optimized to ensure the product achieves optimal performance after vulcanization. As a leading Custom Rubber compound Manufacturers China, we use advanced equipment like ODR rheometers to monitor process parameters, guaranteeing batch-to-batch consistency.

Quality Control and Certification

All products pass international standard tests such as ASTM and GB/T, and we provide complete technical data support. For example, the vulcanization characteristics (like TC90 time controlled at 111-116 seconds) and mechanical property data of the NV series products are transparently disclosed, helping customers make precise selections.

Sustainable Development Philosophy

We reduce the product carbon footprint by using bio-based plasticizers (e.g., ATBC) and recycled fillers. Simultaneously, our positioning as a Full range of rubber compound Manufacturers enables us to provide customers with one-stop Rubber Plastic Blend Customization Services, including technical consultation, sample customization, and after-sales support.

5. Industry Trends and Future Outlook

With the advancement of smart manufacturing and the green economy, Market Trends for High-Performance Rubber Materials are moving towards multifunctionality, environmental friendliness, and intelligence. NBR PVC Rubber Compounds possess great potential in blending and modification due to their adjustable molecular structure. For example, enhancement with nano-fillers (like silica) can further improve the material’s thermal conductivity and mechanical strength; while blending with materials like TPE can expand its applications in the medical and consumer goods sectors.

Our company will continue to invest in R&D, promoting the upgrade of our Rubber Compound R&D Capabilities, and plans to launch biodegradable NBR PVC rubber blends before 2025, responding to global carbon neutrality goals. At the same time, we will strengthen cooperation with universities and research institutions to explore innovative applications of materials in new energy and electronic packaging.

6. Conclusion

NBR PVC Rubber Compounds, as a significant breakthrough in rubber-plastic material technology, not only solve pain points in multiple industries but also bring tangible value through cost reduction and efficiency improvement for enterprises. Choosing an established NBR PVC Rubber Compound Manufacturer is key to ensuring product performance and reliability. With our full product range as a Full range of rubber compound supplier, profound experience, and comprehensive Rubber Plastic Blend Customization Services, our company is committed to becoming the most trusted partner for global customers. For more information on our Customized rubber compound solutions or technical parameters, please feel free to contact us via our website or contact details. We will provide you with professional technical support.