Abstract

This technical article provides a comprehensive analysis of the GreenThinking® FR98 RP, a high-efficiency, Halogen free flame retardant for rubber compound developed by Sane ZenChem. Leveraging data from application-specific test reports and product documentation, this paper details its mechanism of action, performance characteristics in various rubber matrices—with a focus on Natural Rubber (NR)—and its key differentiators within the broader FR series. FR98 RP is engineered to deliver an exceptional balance of high flame retardancy, robust mechanical property retention, and excellent processing attributes, establishing it as a superior Flame retardant substitute for antimony trioxide and a prime choice among Halogen free environmentally friendly flame retardant Suppliers for environmentally compliant, high-safety rubber components.

1. Introduction: The Need for Advanced Halogen-Free Flame Retardancy

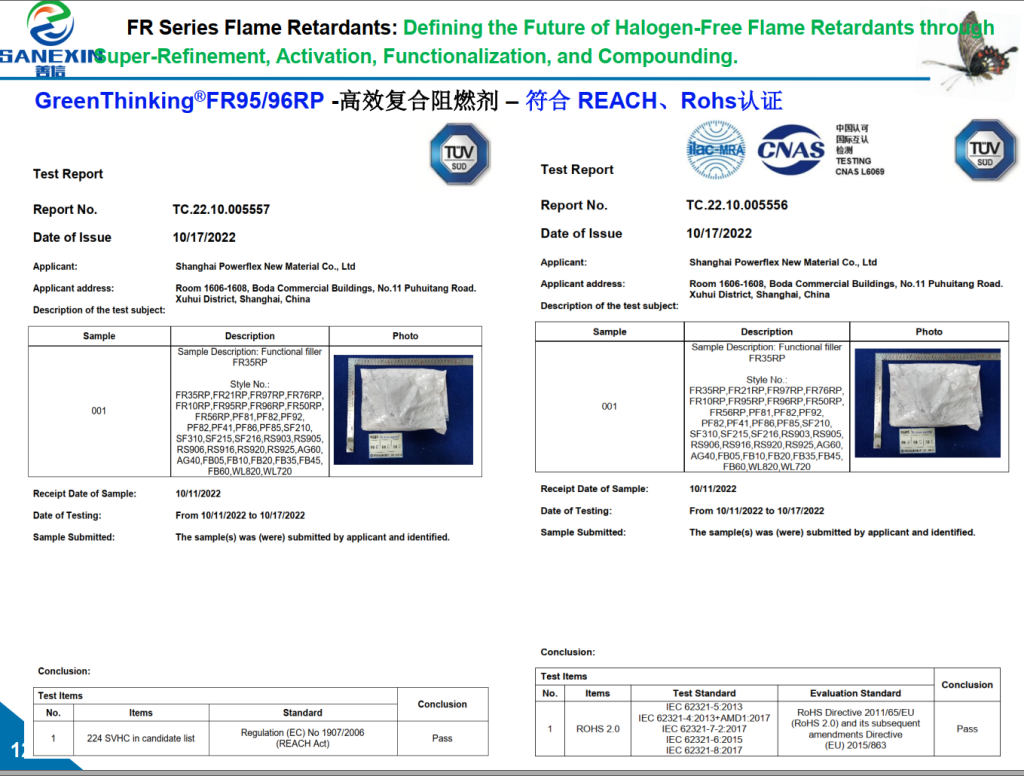

The global shift towards stricter environmental and safety regulations, such as REACH, RoHS, and WEEE, has driven the rubber industry to seek alternatives to traditional halogenated flame retardants. These alternatives must not only provide reliable fire safety, often requiring stringent certifications like Flame retardant UL94 V0, but also preserve the critical physical properties of the rubber compound and maintain efficient processability. The challenge lies in overcoming the typical trade-off where high flame-retardant loading degrades mechanical performance, elasticity, and aging resistance.

The GreenThinking® FR series, offered by leading Productos ignífugos sin halógenos Fabricantes, addresses this challenge through advanced super-refinement, activation, functionalization, and compounding technologies. Within this portfolio, FR98 RP stands out as a specifically formulated, high-performance, Halogen Free Flame Retardant factory product designed to meet these multifaceted demands, particularly excelling as a Flame Retardant for NR compound where maintaining key physical properties is paramount alongside achieving top-tier fire safety.

2. Product Overview and Core Technology

GreenThinking® FR98 RP is a composite flame retardant system characterized by its platelet structure, advanced surface treatment, and optimized particle size distribution. This design ensures superior dispersibility within the rubber matrix, a critical factor for consistent performance and compound homogeneity. The product is 100% halogen-free, containing no bromine, chlorine, fluorine, or antimony trioxide, ensuring full compliance with international environmental directives and positioning it as a true Environmentally Friendly Flame Retardant and a Halogen free flame retardant comply with RoHS Reach.

Flame Retardant Mechanism: The efficacy of FR98 RP is based on a synergistic multi-mode action. Upon exposure to heat and flame, it decomposes and expands on the polymer surface, forming a viscous, insulating charred crust and a porous protective layer. This robust barrier effectively isolates the underlying material from oxygen, retards heat transfer, and traps combustible volatiles. Concurrently, its decomposition promotes reactions that terminate free radical chain reactions (H· and OH·) responsible for flame propagation. This combined physical barrier formation and chemical quenching action results in highly efficient flame suppression with low smoke emission, making it a low smoke halogen free flame retardant.

3. In-Depth Performance Analysis in Natural Rubber (NR)

A dedicated experimental report highlights FR98 RP’s exceptional performance as a Halogen free flame retardant for NR formulation in a 45 Shore A hardness Natural Rubber formulation for molded parts. The data validates its core value proposition: achieving the highest flame retardancy standard without sacrificing fundamental mechanical integrity, truly a flame retardant not affecting hardness.

3.1 Flame Retardancy Performance:

- Result: With an addition level of 45 parts per hundred rubber (phr), a 2mm thick NR test specimen achieved a UL94 Horizontal Burn rating of V-0, characterized by self-extinguishment after flame removal, providing Environmentally friendly flame retardant with UL94 V0 certification.

- Significance: This demonstrates that FR98 RP provides extremely effective Rubber flame retardant low loading high efficiency at a technically viable and commercially relevant dosage, enabling NR components to pass critical safety standards for applications like electrical seals, industrial gaskets, and specialized components.

3.2 Mechanical Property Retention (The Critical Advantage):

The most compelling evidence of FR98 RP’s advanced formulation is its ability to maintain excellent physical properties even at high loading levels, a common pain point with many flame retardants.

- Tensile Strength: The compound retained a tensile strength ranging between 8.45 and 11.81 MPa across tested samples. This indicates that FR98 RP maintains strong polymer chain interactions and does not act as a significant stress concentrator.

- Elongation at Break: Remarkably, the elastomeric nature of the NR was preserved, with elongation at break values between 427% and 497%. This high elasticity is crucial for components undergoing deformation in service.

- Modulus: The modulus values at 100% (M100 ≈ 1.8-1.9 MPa) and 300% elongation (M300 ≈ 5.3-5.8 MPa) indicate a well-reinforced, functional compound suitable for load-bearing applications.

Conclusion for NR: The experimental data conclusively shows that FR98 RP, as an effective NR Flame Retardant, successfully breaks the traditional compromise between flame retardancy and mechanical performance in Natural Rubber. It delivers V-0 safety while preserving the material’s inherent toughness and elasticity, making it an ideal Flame Retardant for NR for high-performance, flame-retardant NR parts.

4. Comparative Performance in Other Rubber Matrices

The FR Series technical document provides a comparative analysis between FR98 RP and its sibling product, FR99 RP, in EPDM and NBR, offering a broader perspective on its behavior.

4.1 In EPDM Formulations:

- Flame Retardancy: Both FR98 RP and FR99 RP enable EPDM compounds (at 70A and 50A hardness) to achieve a UL94 V-0 rating. Notably, FR98 RP consistently delivers a higher Limiting Oxygen Index (LOI)—up to 42.3% compared to 35.4% for FR99 RP in a 70A formula—indicating a superior inherent ability to suppress combustion in a controlled oxygen environment.

- Curing & Physical Properties: The data indicates FR98 RP has a moderating effect on the cure state, resulting in a slightly lower crosslink density (MH-ML) and a longer optimal cure time (TC90) compared to FR99 RP. While FR99 RP shows advantages in tensile strength and heat aging resistance in these specific EPDM formulations, FR98 RP’s performance profile—combining very high LOI with acceptable mechanicals—makes it a potent choice where ultimate flame resistance is the primary driver.

4.2 In NBR Formulations:

- Performance Trade-off Highlighted: In a 70 Shore A NBR base, FR98 RP again demonstrates superior flame retardancy, reflected in a higher LOI (37.8% vs. 32.6%). It yields a vulcanizate with higher elongation at break (522% vs. 455%) and lower modulus. This suggests that in polar rubbers like NBR, FR98 RP can be the preferred option when the application demands maximum flame retardancy coupled with high flexibility and elongation.

5. Key Product Advantages and Application Benefits

Synthesizing the data from all reports, the defining advantages of GreenThinking® FR98 RP are:

- Proven High-Efficiency, Halogen-Free Flame Retardancy: Guarantees compliance with global environmental regulations (RoHS, REACH) while reliably achieving top fire safety ratings like UL94 V-0, making it a key product from retardante de llama sin halógenos respetuoso con el medio ambiente Fabricantes China.

- Exceptional Balance with Mechanical Properties: Particularly outstanding in Natural Rubber, where it preserves high tensile strength and excellent elongation at effective loading levels, solving a major industry challenge and living up to its promise as a flame retardant not affecting hardness.

- Superior Processing Characteristics: Its engineered particle morphology and surface treatment ensure excellent dispersion, improved compound fluidity, and smooth extrusion profiles. This leads to better dimensional stability in finished products and lower mixing energy consumption.

- Specific Performance Leadership: Holds a distinct advantage in maximizing the Limiting Oxygen Index (LOI) across multiple polymer types and provides a favorable property set (high elongation, good flexibility) in certain rubber matrices like NBR.

- Versatile Application Scope: Its validated performance in NR, EPDM, and NBR makes it suitable for a wide range of high-safety rubber components, including but not limited to:

Wire & Cable: Insulation and jacketing requiring V-0 rating.

Industrial Seals & Gaskets: Where flame resistance and elasticity are both critical.

Transportation Components: Seals, hoses, and mounts in mass transit and automotive.

Electrical & Electronic Parts: Connectors, insulators, and protective components.

6. Conclusión

GreenThinking® FR98 RP represents a significant advancement in halogen-free flame retardant technology for the rubber industry. It is not merely a drop-in additive but a strategically engineered solution that masterfully addresses the triad of modern manufacturing demands: regulatory compliance (halogen-free), uncompromised safety (high LOI, V-0 rating), and preserved material performance (mechanical & processing properties).

The experimental evidence, particularly in Natural Rubber, underscores its capability to enable the production of safe, durable, and high-quality components. While the choice between FR98 RP and other members of the GreenThinking® FR series (like FR99 RP) may depend on the specific rubber polymer and the final performance priority—be it ultimate flame resistance, optimal heat aging, or highest tensile strength—FR98 RP stands as the definitive choice for applications where pushing the boundaries of flame retardant efficiency without breaking the backbone of the rubber’s physical properties is the primary objective. It’s important to note that alongside FR98 RP, we have also developed FR99 RP to cater to a different set of performance profiles. We can provide customized solutions based on your specific application requirements. For detailed technical information on FR99 RP, please click here to view the data sheet.

Sane ZenChem (Shanghai) Co., Ltd., a prominent Halogen free flame retardant Suppliers China, is not only a provider of innovative material solutions but also a partner with robust in-house manufacturing capabilities. To ensure the consistent excellence and reliable supply of our GreenThinking® FR Series halogen-free flame retardants, we have established dedicated, advanced production lines specifically for the FR Series within our customized silicone and specialty material manufacturing facilities.

Our manufacturing strengths are demonstrated in the following areas:

- Dedicated Lines for Focused Production: These lines are designed specifically for the precision manufacturing of the FR Series, ensuring that the entire process—from raw material handling and compounding to packaging—takes place in a controlled, dedicated environment. This eliminates cross-contamination and guarantees exceptional batch-to-batch consistency.

- End-to-End Quality Control: Leveraging the R&D and production foundation of our group company, Anhui Sanexin Polymer Fine Material Co., Ltd., we implement comprehensive quality control across the entire chain, from core raw material selection and formulation optimization to scaled production. Our FR laboratories work in close synergy with the dedicated production lines, ensuring every batch shipped meets stringent performance standards.

- Flexible, Customized Production Capacity: With our deep technical understanding of flame retardants and a flexible production system, we can not only reliably supply standard grades like FR98RP and FR99RP but also offer customized product development and production services tailored to specific client needs, such as unique rubber matrices, extreme performance requirements, or specialized processing techniques.

- Scalability and Compliance Assurance: Our professional production lines signify our capacity for large-scale, high-efficiency manufacturing, capable of fulfilling bulk order requirements from global clients. Simultaneously, the entire production process strictly adheres to environmental regulations, ensuring continuous compliance with international standards such as REACH and RoHS.

From innovative formulations in the lab to precise manufacturing on dedicated lines, we have built a complete value chain. This means that when you choose the GreenThinking® FR Series from Halogen free environmentally friendly flame retardant Manufacturers, you receive not only a proven technical solution but also high-quality products traceable to our own facilities and backed by responsive customization services. We are committed to transforming this solid manufacturing capability into a competitive advantage for your product success and market leadership.

Partner with us to co-develop and define the future.