Introduction: Challenges and Opportunities for High-Performance Sealing Materials in Extreme Environments

As modern industry advances towards higher precision and sophistication, equipment faces increasingly harsh environments – from the high temperature and pressure within new energy vehicle battery packs to the extreme heat and cold of aerospace engines; from the pure yet corrosive gases in semiconductor manufacturing to the strong acids and alkalis in the petrochemical industry. Traditional rubber sealing materials often fall short under these extreme conditions, with performance degrading rapidly, becoming a weak link in system reliability.

Fluorocarbon Rubber (FKM) has emerged as a solution. With its exceptional high-temperature resistance, excellent chemical resistance, and outstanding long-term aging performance, it has become the “ace material” in the high-end sealing field. However, FKM is also notoriously “effective yet difficult to use”: its compounding process is complex, vulcanizing agents are difficult to disperse, and achieving consistent performance is challenging, discouraging many manufacturers.

This article will delve into the typical applications of FKM in key industries, reveal common industry pain points, and systematically introduce how Anhui Lixin Rubber Technology Co., Ltd., under the SaneZen Group, leverages innovative FKM Premix Technology and robust Intelligent Manufacturing Capabilities to provide customers with stable, reliable, and high-performance sealing material solutions. As a leading High Performance FKM Compound Supplier y Custom FKM Rubber Compound Manufacturer, we help Chinese high-end manufacturing overcome material bottlenecks.

I. Typical Application Fields of FKM Materials: The “Safety Line” Guarding Critical Systems

1. New Energy Vehicles: Sealing Upgrades in the Electrification Wave

The proliferation of electric vehicles (EVs) and hybrid electric vehicles (HEVs) brings new demands for sealing materials in their powertrain systems, making FKM Premixed Rubber for Automotive highly sought after.

- Battery System Sealing: Battery modules and packs require seals with excellent resistance to coolants (often ethylene glycol-based), long-term heat resistance (>150°C), and superior electrical insulation, along with extremely low volatile organic compound (VOC) emission to prevent battery corrosion. This creates a strong demand for specialized FKM compound for electric vehicle battery seals.

- Motor and Electric Control Sealing: High-speed motors generate significant heat, requiring bearing seals and housing seals to maintain elasticity under sustained high temperatures. FKM’s resistance to thermal aging makes it an ideal choice.

- Fuel System and Hydrogen Energy System Sealing: For plug-in hybrids or hydrogen fuel cell vehicles, seals must withstand new fuels like biodiesel (RME), synthetic fuels, or high-pressure hydrogen. FKM’s excellent tolerance to various fuels and additives ensures long-term sealing safety, positioning it as a key Fuel Resistant FKM Compound Formulation.

2. Aerospace and Defense: Reliable Assurance in Extreme Environments

This is one of the most demanding fields for material performance, where FKM is an irreplaceable key material, especially for High Temperature FKM Sealing Material y FKM Rubber Compound for Aerospace.

- Engine System Sealing (e.g., O-rings, gaskets): Constantly exposed to high-temperature lubricating oils and hot air exceeding 200°C, requiring materials with extremely low compression set and excellent thermal aging stability, often fulfilled by high temperature FKM O rings for aerospace.

- Hydraulic and Fuel System Sealing: Systems operate under extremely high pressure with media including phosphate ester hydraulic oils, jet fuel, etc., across a very wide temperature range (-55°C to over 200°C). FKM’s broad temperature operating range and media compatibility are crucial, making it a preferred FKM premix for hydraulic seals in industrial machinery and for aerospace.

- Vacuum and Inert Gas Sealing: Used for spacecraft hatches, observation windows, and propulsion systems. FKM’s extremely low gas permeability and resistance to space radiation and atomic oxygen erosion ensure long-term in-orbit sealing for spacecraft.

3. Petrochemical and Energy: The “Steel Great Wall” Against Chemical Media

In highly corrosive environments, seal failure can lead to catastrophic consequences, driving the need for FKM Compound for Harsh Environments y FKM Premix for Oil and Chemical Resistance.

- Valve, Pump, and Reactor Sealing: Directly contacting various highly corrosive media such as sulfuric acid, hydrochloric acid, hydrocarbon solvents, and amines. FKM’s outstanding chemical resistance makes it the first choice for sealing in chemical process equipment, establishing SaneZen as a reliable chemical resistant FKM gasket material supplier.

- High-Temperature Steam and Superheated Water Sealing: Used in power plant valves and steam pipelines. FKM maintains mechanical strength and sealing performance in high-temperature, high-pressure steam environments, preventing “steam erosion,” thus serving as a critical FKM material for high pressure steam applications.

4. Semiconductor and Electronic Manufacturing: The “Dust-Free Guardian” in Ultra-Pure Environments

The purity of the manufacturing process directly determines chip yield.

- CVD/PVD Equipment Sealing: Operates in plasma environments and various high-purity, highly reactive process gases (e.g., silane, carbon tetrafluoride, helium), requiring materials resistant to plasma erosion, with low outgassing and no metal ion leaching. This necessitates specialized FKM premixed rubber for semiconductor equipment.

- Ultra-Pure Water and Chemical Delivery System Sealing: Used in wafer cleaning and etching processes. FKM’s high cleanliness and low extractables meet the semiconductor industry’s demand requirements for contamination control.

II. Pain Points and Challenges in Industry Application: Four Major Difficulties in FKM “Implementation”

Despite FKM’s superior performance, the path from material to reliable component is fraught with obstacles, which a proficient FKM Rubber Compound Manufacturer in China must address.

Table 1: Analysis of Main Pain Points in FKM Industry Applications

| Pain Point Category | Specific Manifestations | Consequences |

| Complex Processing | High Mooney viscosity of raw gum leads to high mixing energy consumption; Vulcanizing agents (e.g., Bisphenol AF/BPP) are extremely difficult to disperse, prone to clumping. | Uneven mixing, fluctuating product performance; Low production efficiency, high energy consumption; Localized over-cure or under-cure, causing defects. |

| Difficulty Ensuring Performance Consistency | Batch-to-batch variations in Mooney viscosity, curing curves, mechanical properties; Difficulty predicting long-term thermal aging and media immersion performance decay curves. | Unstable end-product yield; Unreliable equipment seal life, increasing maintenance costs and risks. |

| Cost and Delivery Pressure | High-end FKM raw gum relies on imports, is expensive and price-volatile; Slow response to small-batch, multi-variety customization demands. | High comprehensive costs; Long new product development cycles, affecting market responsiveness. |

| Environmental and Compliance Requirements | Need to comply with hazardous substance restriction regulations like RoHS, REACH; Industry-specific certifications required for automotive, medical, etc. | Limited material selection and formulation design; High barriers to entry for export markets. An ISO certified FKM compound supplier in China like SaneZen helps navigate these. |

These pain points constrain the willingness and ability of many enterprises, especially small and medium-sized ones, to use high-performance FKM. They urgently need a ready-to-use, stable performance , supply-reliable FKM compound solution.

III. Technical Advantages of SaneZen FKM Premix: Confronting Pain Points, Providing Stable Solutions

Addressing the above industry pain points, Anhui Lixin Rubber Technology has launched the LXF Series FKM Premix. This product is not simply a mix of raw rubbers but a systematic solution based on deep understanding.

1. Core Technology: Premix Process, Solving Processing Challenges

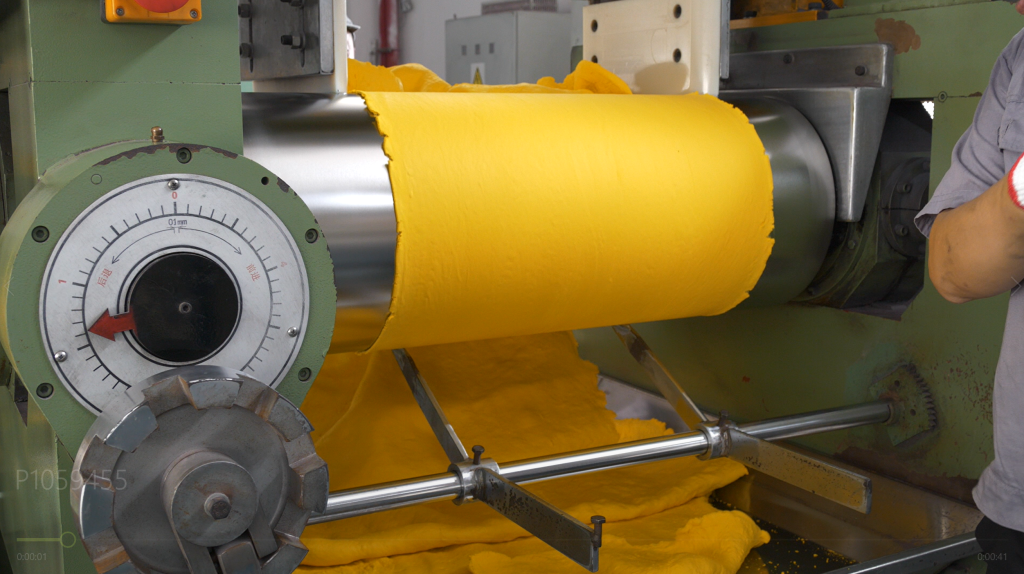

We pre-mix FKM raw gum with the complete vulcanization system additives (vulcanizing agents, accelerators, acid acceptors, etc.) and some processing aids and fillers under strictly controlled processes, and sheet out the compound into a uniform “Premix”.

The significance of this innovation is:

- Greatly Simplifies Customer Production Process: Customers no longer need complex multi-phase batching and long mixing times; they only need to briefly mix the premixed sheets with the remaining reinforcing fillers (e.g., carbon black N990), significantly lowering the technical threshold and energy consumption.

- Achieves Optimal Dispersion of Vulcanizing Agents: During the premix stage, special processes ensure uniform dispersion, fundamentally solving the core pain point of vulcanizing agent “clumping” and uneven distribution, ensuring highly consistent curing characteristics for every batch.

Enhances Processing Safety & Convenience: The premixed compound in sheet form reduces heat generation and scorch risk, and facilitates easy weighing, handling, and feeding, making subsequent processes like calendering and extrusion smoother and more efficient.

2. Excellent and Verifiable Comprehensive Performance

Our models like LXF100CA/LXF200CA undergo rigorous internal and third-party testing, with transparent and reliable performance data, exemplifying a Low compression set FKM compound manufacturer‘s commitment to quality.

Table 2: Key Performance Data Overview of SaneZen FKM Premix (Example: LXF100CA)

| Performance Category | Norma de ensayo | Unidad | Valor típico | Performance Interpretation |

| Basic Physical Properties | ||||

| Dureza (Shore A) | ASTM D2240 | Punto | 70 | Moderate hardness, balancing sealing force and assemblability. |

| Resistencia a la tracción | ASTM D412 | MPa | 11.28 | Provides sufficient mechanical strength to withstand pressure冲击. |

| Alargamiento a la rotura | ASTM D412 | % | 257 | Good toughness, adapting to complex installation and deformation. |

| Heat Aging (200°C×504h) | ||||

| Cambio de dureza | ASTM D2240 | Punto | 3 | Minimal change, excellent hardness stability at high temperature. |

| Tensile Strength Change Rate | ASTM D412 | % | -4.2 | High strength retention rate, excellent long-term thermal aging performance. |

| Oil Resistance (FAM B, 23°C×48h) | ||||

| Cambio de dureza | ASTM D2240 | Punto | -6 | Good oil swell resistance. |

| Volume Change Rate | ASTM D471 | % | 10.5 | |

| Biodiesel Resistance (RME, 80°C×504h) | Relevant for FKM rubber for biodiesel fuel system seals. | |||

| Volume Change Rate | ASTM D471 | % | 3.1 | Excellent tolerance to new biodiesel fuels. |

| Compression Set (150°C×24h) | ASTM D395 | % | 26.48 | Strong elastic recovery ability, a key indicator for ensuring long-term sealing effectiveness. |

| Low-Temperature Performance (TR10) | GB 7758 | °C | -20 | Meets the low-end requirements of most wide-temperature-range applications, offering FKM rubber compound with good low temperature flexibility. |

3. Future-Oriented Customization Capabilities

We not only provide standard grades but also possess strong “Formulation Library”-supported customization capabilities.

- Media-Specific Optimization: Formulas can be adjusted based on the specific media customers encounter (e.g., specific types of lubricating oil, coolant, chemicals) to achieve optimal resistance.

- Process Adaptability Adjustment: The compound’s rheological properties can be adjusted for different customer processes like extrusion, molding, and injection molding to improve production efficiency and yield.

- Functional Modification: Can provide special FKM compounds with conductivity, thermal conductivity, high wear resistance, or coloration.

IV. SaneZen Group Manufacturing Strength and Capacity Assurance: The Solid Foundation Behind excellent Performance

Excellent product performance and stable supply rely on a strong R&D and manufacturing system. SaneZen Group’s production base in Xuancheng, Anhui, embodies this solid foundation.

Illustration: Overview of the core competitiveness of SaneZen Group’s rubber compounding business.

1. Full Industry Chain Coverage and Profound Technical Accumulation

- 33+ Rubber Types Full Coverage: From general-purpose NR, SBR, EPDM to special types like FKM, HNBR, VMQ, AEM, we possess a comprehensive material knowledge base and formulation technology, able to provide cross-material system solutions.

- 20+ Years of Professional Experience and Extensive Formulation Library: Over 20 years of industry dedication have accumulated over 10,000 verified rubber formulations. This is not just a database but crystallized experience for solving various application challenges, enabling rapid response to customer customization needs.

2. Large-Scale, Specialized Intelligent Manufacturing Capacity

- Annual Output 150,000+ Tons: Huge production capacity ensures our ability to guarantee supply for large customers and long-term orders, enabling stable delivery even during market fluctuations.

- 26+ Specialized Production Lines: Production lines are configured professionally according to rubber type and process characteristics. Among them, special rubber dedicated production lines (including FKM dedicated lines) are completely independent, eliminating the risk of cross-contamination during production with other rubber types.

- Independent Color Matching Workshop: Dedicated to the production of colored rubber products, independently controlled from batching to mixing, ensuring color consistency and purity, meeting stringent color requirements in automotive, consumer electronics, and other fields.

3. Strict Quality Control and Compliance System

We have established a full-process quality monitoring system from raw material to storage to finished product out of factory, with key raw material batches traceable and production process parameters monitored in real-time. The factory has passed international management system certifications like ISO 9001 and is committed to meeting stricter standards like IATF 16949 for the automotive industry, ensuring every batch of FKM premix delivered meets specifications.

V. Conclusion: Partner with SaneZen to Drive Industrial Upgrade Through Material Innovation

In today’s increasingly competitive high-end manufacturing landscape, the performance boundaries of materials often determine the technological height of products. As the pinnacle of sealing materials, the depth and breadth of FKM application directly reflect the reliability level of a country’s high-end equipment.

The SaneZen Group and its subsidiary Anhui Lixin Rubber Technology are not merely an FKM Rubber Compound Manufacturer in China but strive to be a strategic partner for customers on their material application journey. We address processing pain points through innovative premix products, convey performance confidence through transparent and verifiable data, and ensure supply security through a large-scale, specialized manufacturing system.

We look forward to partnering with leading companies in new energy vehicles, aerospace, semiconductors, petrochemicals, and other fields to jointly to solve sealing challenges under extreme operating conditions. Through breakthrough material innovation, we aim to empower Chinese and global high-end manufacturing, co-creating a more reliable, efficient, and sustainable industrial future.

To learn more about our products or obtain technical support, please visit: www.sanezenrubber.com

Or contact:

- Business & Technical Support Center: Room 1606-1608, Boda Business Building, No. 11 Puhuitang Road, Xuhui District, Shanghai, China

- Phone/WhatsApp : +86 136 7164 1995

- Email: yorichen@sanezen.com