Introduction: Material Selection Determines Equipment Fate in Extreme Conditions

In 2022, an offshore drilling platform in Northern Europe suffered a hydraulic system leak due to the embrittlement and failure of conventional silicone rubber seals in low-temperature environments, resulting in direct losses exceeding €1.8 million from production shutdown and repairs alone. Similar cases are not uncommon in high-precision fields such as aerospace, petrochemicals, and military equipment. A recent report in the International Journal of Sealing Technology pointed out: “Over 40% of seal failures stem from insufficient material performance under extreme temperature, media, or radiation conditions.”

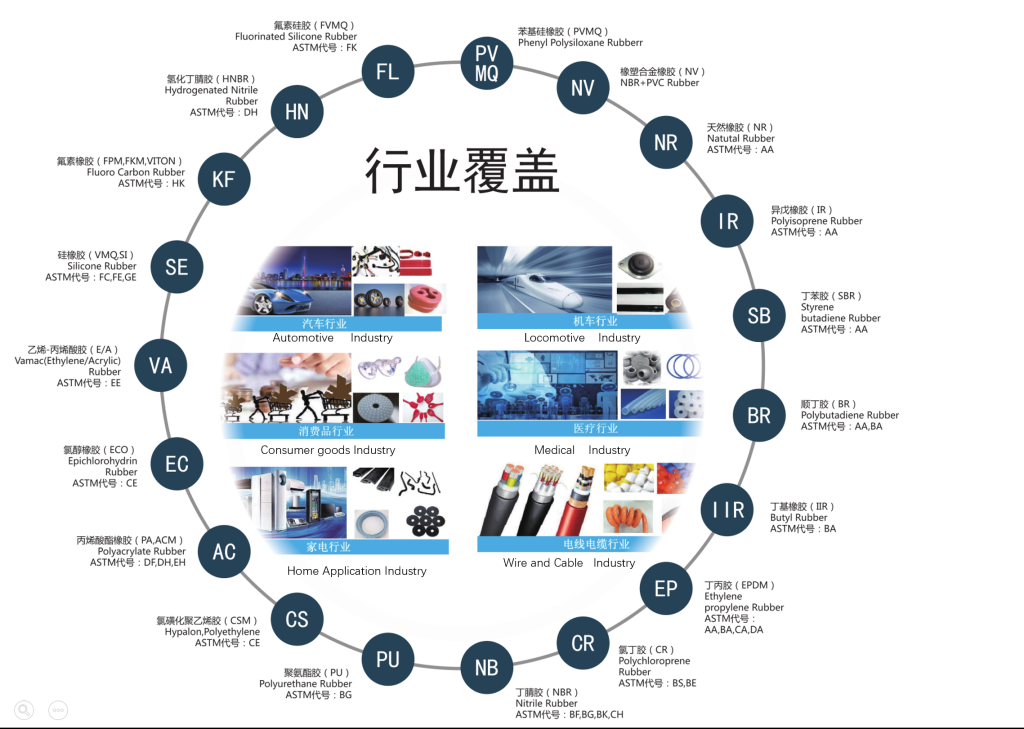

Como líder Phenyl Silicone Rubber (PVMQ) manufacturer in China and a Custom Silicone Compounds factory, we are acutely aware of this critical issue. In response, we have successfully developed the SR32XXUDP series Phenyl Silicone Rubber compound. This series not only redefines the performance boundaries of sealing materials but also, with its exceptional stability and broad adaptability, has become a reliable choice for tackling severe challenges. This product line leverages our advanced manufacturing base in Xuancheng, Anhui – China’s first professional dust-free colored mixing workshop for silicone rubber – ensuring purity and precision throughout the entire process from raw materials to finished products. We stand as a premier PVMQ silicone rubber manufacturer in China y un custom silicone rubber compound manufacturer.

Part 1: Phenyl Silicone Rubber (PVMQ) – A Performance Leap from Molecular Design

1.1 PVMQ vs. Common VMQ: A Dimensional Upgrade in Materials Science

Common Methyl Vinyl Silicone Rubber (VMQ) is widely used for its good temperature resistance and flexibility, yet its performance ceiling remains evident in extreme environments. Phenyl Silicone Rubber (PVMQ), by introducing phenyl groups into the siloxane side chains, achieves a comprehensive breakthrough in performance, making it the best silicone rubber for extreme cold applications and high-temperature scenarios:

Performance Dimension Common Methyl Silicone Phenyl Silicone Key to Performance

Rubber (VMQ) Rubber (PVMQ) Improvement

Low-Temperature Approx. -60°C Down to -100°C The introduction of phenyl groups disrupts the regularity of molecular chains, significantly lowering the glass transition temperature, imparting softness and elasticity in extreme cold.

Elasticity Limit

High-Temperature Long-term use ~200°C Long-term use up The steric hindrance and electron cloud shielding effect formed by the benzene ring effectively inhibit molecular chain degradation and rearrangement at high temperatures.

Stability to 250°C

Radiation Resistance Poor Excellent The benzene ring structure can absorb and dissipate radiant energy, protecting the siloxane backbone, meeting requirements for nuclear and aerospace industries – a key feature of radiation resistant silicone for aerospace seals.

Resistance to Fair Significantly Improved resistance to swelling in non-polar solvents (e.g., fuels, lubricating oils), contributing to high performance rubber for oil and gas industry applications.

Solvents/Fuels Improved

Core Mechanism: According to the Chinese National Standard GB/T 5576-1997, the “electron cloud shielding effect” of the phenyl groups in PVMQ acts like a “protective armor” for the siloxane backbone, effectively defending against high-energy radiation, chemical erosion, and thermal-oxidative attack. This is the fundamental reason for its stable performance across a wide temperature range (-100°C to 250°C), making it an ideal rubber material for seals between -100°C to 250°C and a high temperature aging resistant silicone rubber compound.

1.2 Data Speaks: The Measured Performance Profile of the SR32XXUDP Series

Our SR32XXUDP series offers a variety of hardness options to meet the needs of different sealing structures. Below are its core mechanical property data (tested per ASTM standards), demonstrating its capability as a low compression set silicone rubber for hydraulic seals:

Basic Physical Properties

Grade Hardness Tensile Elongation at Tear Strength Brittleness

(Shore A) Strength Break (%) (kN/m) Temperature

(MPa)

SR3250UDP 50 ±5 ≥ 9.5 ≥ 550 ≥ 28 ≤ -100°C

SR3270UDP 70 ±5 ≥ 10.2 ≥ 400 ≥ 35 ≤ -100°C

SR3280UDP 80 ±5 ≥ 9.2 ≥ 140 ≥ 19 ≤ -100°C

Property Retention After Thermal Aging (72 hours at 225°C)

- Hardness Change: Increases by only 2-8 points (common VMQ may surge by 40+ points), indicating an extremely slow hardening trend.

- Tensile Strength Retention: > 90%

- Elongation Retention: SR3270UDP can maintain >77.5%

- Key Value: Minimal property changes mean the seal can maintain reliable contact pressure and sealing compensation ability after long-term high-temperature service, avoiding failure due to material hardening, ensuring high reliability seals for chemical processing plants.

Part 2: Conquering Industry-Specific Challenges – PVMQ in Practical Application

2.1 New Energy Vehicles & Power Equipment: Addressing New Demands for High Voltage and Thermal Management

Industry Pain Point: The three-electric systems (battery, motor, electronic control) of electric vehicles impose new sealing requirements: resistance to high/low-temperature cycling, flame retardancy, insulation, and low volatility. Traditional materials struggle to balance all.

PVMQ Solution:

- Wide-Temperature Sealing: Battery pack cooling system seals need to remain elastic from -40°C cold starts to above 100°C thermal shock. PVMQ fully covers this range.

- Arc & Tracking Resistance: Excellent inherent electrical insulation, combined with customizable high flame-retardant formulations (UL94 V-0 certified), suitable for high-voltage connector and charging pile seals.

- Case Study: A leading domestic battery manufacturer adopted our custom SR3270UDP formula as fire-proof sealing strips between battery modules, successfully withstanding the harsh test of high-temperature ejecta during nail penetration tests.

2.2 Semiconductor & Photovoltaic Manufacturing: The Guardian of Reliability in Ultra-Clean Environments

Industry Pain Point: In chip processing and photovoltaic laminate processes, seals must not only withstand high temperatures and corrosive cleaning gases (e.g., O₃, NF₃) but also be absolutely clean, eliminating ionic contamination and particle outgassing.

Our Edge:

- Cleanroom Production Guarantee: All products for this field are mixed, extruded, and packaged in our Class 1000 cleanrooms, controlling contamination at the source – a testament to our capability in providing cleanroom produced silicone for contamination sensitive applications.

- Low Volatility, Low Extractables: Optimized formulations keep volatile organic compounds (VOCs) and extractables at extremely low levels, meeting SEMI standards.

- Application Points: O-rings for wafer handling robots, door seals for CVD equipment, high-temperature sealing blankets for photovoltaic laminators, etc.

2.3 Deep Earth Exploration & Marine Engineering: Beyond Extreme Pressure and Chemical Corrosion

Industry Pain Point: High temperature (>150°C), high pressure, H₂S/CO₂-rich acidic environments in 10,000-meter deep wells, and the need for long-term seawater corrosion resistance in deep-sea equipment.

PVMQ’s Outstanding Performance:

- Exceptional Resistance to Acidic Gases: Volume swell <3% in 10% H₂SO₄ solution (ASTM D471), far superior to many specialty rubbers.

- Good Shape Retention Under High Pressure: Even under high pressure and temperature cycling, its compression set is significantly lower than ordinary silicone rubber, ensuring lasting seal effectiveness, ideal for demanding oil and gas industry needs.

- Track Record: Our materials have been applied in Christmas tree valve seat seals for onshore sour gas fields and hydraulic system seals for Deep-sea ROVs (Remotely Operated Vehicles), with stable service performance.

Part 3: Core Advantages – Why Choose Us as Your PVMQ Partner?

3.1 Manufacturing Backbone from Xuancheng, China’s “Silicone Valley”

Our factory is located in Xuancheng, Anhui, renowned as the “Hometown of China’s Four Treasures of the Study”. This area boasts not only a beautiful natural environment and consistently excellent air quality but has also fostered a high-precision eco-system for new chemical materials. Here, we have built China’s first professional dust-free colored mixing workshop for silicone rubber. This is not merely a hardware investment but the cornerstone of our commitment to “pure quality,” solidifying our position as a leading Phenyl Silicone Rubber compound manufacturer in China.

3.2 Visible Quality: Full Process Control from Workshop to Warehouse

1. Intelligent Production Workshops

Our production lines are equipped with fully automatic batching systems, internal mixers, and open mills. Key process parameters (temperature, pressure, time) are monitored and recorded in real-time by a central control system. The Class 1000 cleanrooms ensure that products, especially light-colored or highly transparent ones, are free from dust contamination.

2. Rigorous Laboratory Verification System

The factory laboratory is equipped with comprehensive testing equipment, including Mooney viscometers, Moving Die Rheometers (MDR), universal material testing machines, high/low-temperature chambers, ozone aging test chambers, etc. Every batch of raw materials is inspected upon receipt, and every batch of product is tested upon completion. Data is directly linked to production batches, enabling full traceability.

3. Standardized & Efficient Warehousing & Logistics

The finished product warehouse is temperature and humidity controlled (<30°C, <50% RH), ensuring product performance remains as fresh throughout its 12-month shelf life. Products are packaged in 20 kg/box vacuum moisture-proof packaging, effectively preventing moisture absorption that could affect subsequent processing. Our in-house logistics team works closely with multiple international logistics companies to ensure safe and timely delivery to customers worldwide – a crucial aspect for clients looking for where to buy custom silicone rubber compound.

3.3 Deep Customization Capability: Your Needs, Our Formulation

Como specialty silicone rubber supplier and a Custom silicone manufacturer for military applications and other demanding sectors, we reject a “one-size-fits-all” approach. Our technical team, with over 25 years of industry experience, can perform deep customization based on your specific application scenario:

- Performance Customization: Hardness (10-90 Shore A), tensile strength, tear strength, flame retardancy rating (UL94), conductive/insulative properties, etc.

- Process Adaptation: Formulas can be adjusted for suitability in molding, extrusion, calendaring, or Liquid Silicone Rubber (LSR) injection molding.

- Appearance Customization: Leveraging dust-free colored mixing technology, we can accurately match any Pantone or RAL color code with stable, non-migrating, non-fading colors.

- Compliance Support: Assistance with product certifications such as FDA (for Silicone rubber with FDA certification for food contact), USP Class VI, RoHS, REACH, UL, etc.

3.4 Empowering Customer Technical Service Network

We sell not just products, but solutions:

- Free Material Selection Consultation: A team of over 30 senior engineers provides technical support to help you make the optimal choice from a vast array of materials.

- Rapid Prototyping Response: We offer quick sample services. For standard products, sample mold lead times can be shortened to 7 working days.

- On-Site Failure Analysis: For critical applications or failure cases, our engineers can provide on-site technical support and root cause analysis.

Part 4: Collaboration for Mutual Success – The Process of Partnering with a Leading Phenyl Silicone Rubber Supplier

4.1 Our Closed-Loop Quality Management

- Source Control: All base polymers and fillers undergo instrumental testing like FTIR (Fourier Transform Infrared Spectroscopy) before warehousing to ensure purity and consistency.

- Process Monitoring: Online rheometers are used during production to monitor curing characteristics in real-time, ensuring process stability for every batch.

- Finished Product Release: Every batch of finished product undergoes full physical property testing. Accelerated aging tests (e.g., 72-hour hot air aging) are conducted regularly to verify long-term performance.

- Continuous Improvement: A system linking customer feedback with production data is established for continuous optimization of formulas and processes.

4.2 Easy Pathways to Start Cooperation

For R&D & Engineers:

- Document Access:

The Selection Guide for Phenyl Silicone Rubber (PVMQ) in Extreme Environments

- Sample Request: Request a free SR32XXUDP series sample kit (including 3 common hardness grades)

For Procurement & Supply Chain Teams:

- Direct Contact:

- Email: yorichen@sanezen.com

- Phone: +86 21 6487 9251 -114

- WhatsApp: +86 136 7164 1995

- Visit & Tour: Welcome to schedule a visit to our advanced production base in Xuancheng, Anhui, to witness the birth of quality firsthand.

Conclusion: Defining the Future of Sealing Materials with Chinese Innovation

In today’s reshaping global industrial chain, choosing a supplier is not just about selecting a product, but also about choosing the manufacturing system, quality philosophy, and innovation capability behind it. While ordinary proveedores de caucho de silicona still compete in the red ocean of price, as a Phenyl Silicone Rubber (PVMQ) manufacturer grown in China, we insist on pursuing a high-value path centered on “Performance per Cost Yuan.”

Our factory in Xuancheng has an annual production capacity of 50,000 tons of high-performance silicone rubber compounds, supported by over 20 modern production lines. However, scale is not our only pride. Our unique competitive edge is built upon ±0.5% batch-to-batch consistency control precision, 72-hour rapid prototyping response, and that one-of-a-kind dust-free colored mixing workshop in China. Together, these constitute our irreplicable core competencies. It is precisely for these reasons that we have become a trusted partner for numerous industry leaders across 37 countries worldwide – including multiple Fortune 500 companies – in the field of specialty sealing solutions.

The future is here. As we move towards industrial challenges with higher/lower temperatures, stronger radiation, and more complex media, Phenyl Silicone Rubber (PVMQ) is playing an increasingly critical role. We look forward to leveraging excellent materials science and robust Chinese manufacturing to open a new chapter in sealing technology with you, safeguarding your critical equipment, and driving the world’s safe operation.