In high-silica-filled tire compound systems, the dispersion state of fillers and interfacial interactions are key to determining dynamic mechanical properties. Through systematic rheological and dynamic mechanical analysis, this paper elucidates how SaneZen Group’s EG22 Filler Enhancer (as an efficient Silica Reinforcement Enhancer y Tire Filler Dispersion Agent) effectively weakens the Payne Effect (providing a Payne Effect Solution) and reconstructs the filler network by promoting silanization reactions and steric hindrance effects. Experimental data show that this technical approach can simultaneously achieve a significant reduction in rolling resistance (60°C tan δ) (through Chemicals improves Low Rolling Resistance) and a notable improvement in wet grip (0°C tan δ) without sacrificing any single performance, while ensuring comprehensive optimization of processability, tear strength, and heat aging resistance. This provides a first-principles-based Chemical solution for Payne effect for breaking the “magic triangle” of tires. Additionally, this study explores the potential application of Bio based tire filler to support sustainable development.

1. Introduction: The Scientific Challenge from “Performance Trade-offs” to “Essential Optimization”

In the field of rubber composites, especially in silica-based green tire formulations, the mutual constraints among rolling resistance, wet grip, and wear resistance represent a classic physics challenge. Traditional solutions often rely on empirical adjustments of formulation components, frequently falling into a “trade-off” dilemma. The root cause lies in the strong self-aggregation tendency of high-surface-area silica fillers in non-polar rubber matrices, forming an imperfect filler network. This microstructure manifests as a significant Payne Effect under dynamic deformation—i.e., the storage modulus (G’) decreases markedly with increasing strain amplitude. The strong Payne Effect is the source of three main technical pain points in high-performance tires:

- High hysteresis loss: Friction between filler agglomerates and the destruction-reconstruction process lead to high rolling resistance.

- Non-uniform stress distribution: Weak filler-rubber interfaces limit effective response to road excitations at low temperatures (around 0°C), reducing wet grip.

- Stress concentration points: These cause decreased tear strength and accelerate thermal aging due to localized heat generation.

Therefore, the core issue shifts from “how to balance the three” to “How to reduce Payne effect in tire tread” and “Improve wet grip without sacrificing rolling resistance“. This paper aims to demonstrate the feasibility and superiority of this technical path through experimental data on EG22, providing an essential optimization solution for the Payne Effect.

2. Mechanism of Action: The Dual Roles of EG22 as “Interfacial Compatibilizer” and “Dispersion Stabilizer”

EG22 is not a traditional processing aid or coupling agent; its molecular structure is precisely designed to play two core roles in the complex mixing process:

- “Catalyst” for silanization: Its molecules effectively reduce the energy barrier for the reaction between silane coupling agents (e.g., Si69) and silica surface silanol groups, improving silanization efficiency. This enables more silica particles to connect to rubber molecular chains via chemical bonds rather than physical accumulation.

- “Inhibitor” of filler agglomeration: Through steric hindrance formed by its long-chain alkyl structure on the filler surface, it effectively prevents the re-agglomeration of silica particles during later mixing and storage, ensuring dispersion stability (serving as an efficient Filler enhancer for silica silane system).

The synergy of these two mechanisms is key to transforming the filler network from a fragile “physical agglomeration” structure to a stable “chemical cross-linking” structure. Simultaneously, EG22 acts as a Tire compound processing aid low Mooney viscosity, significantly improving processing fluidity.

3. Experimental Demonstration: Performance Evolution from Rheology to Dynamic Mechanics

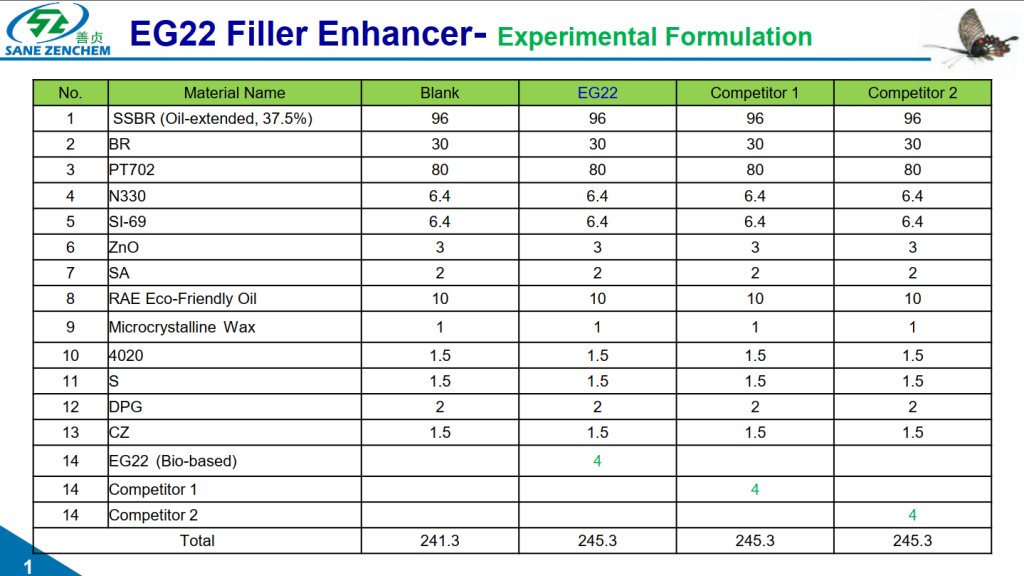

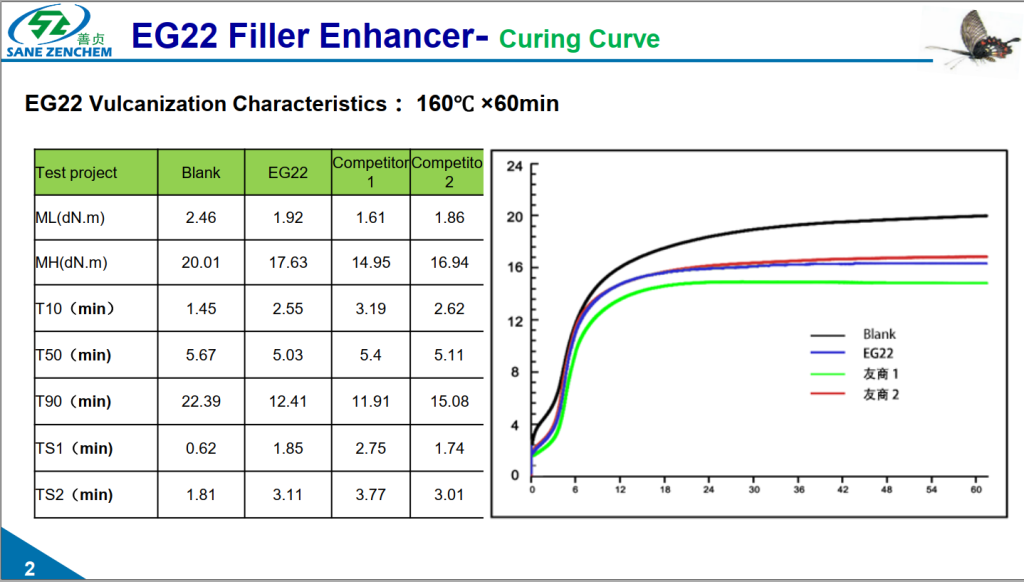

The following data are derived from laboratory comparative tests under strictly controlled variables, systematically evaluated through Dynamic mechanical analysis tire performance improvement.

3.1 Processability and Network Structure: Rheological Evidence

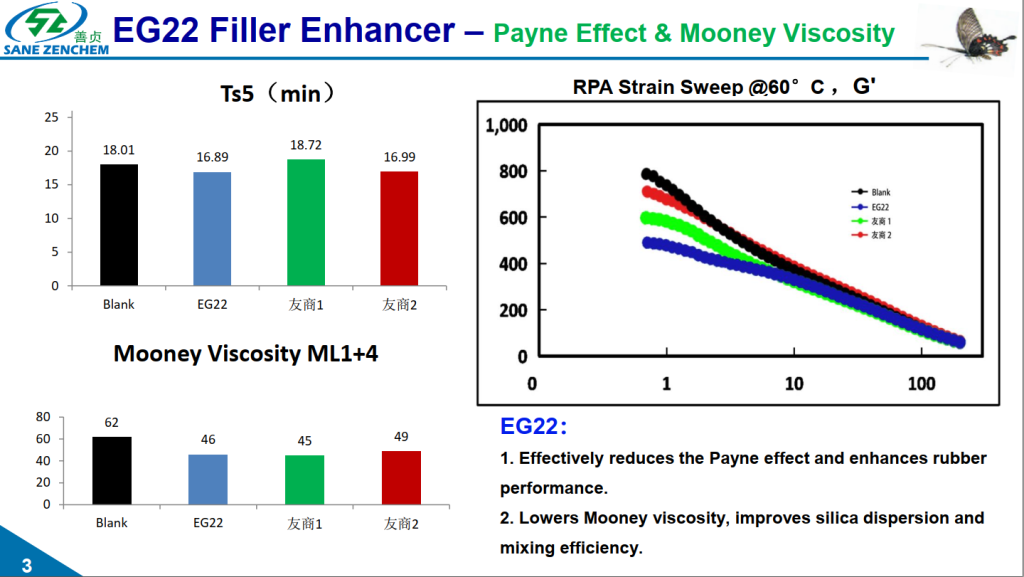

Mooney viscosity analysis: Data show that after adding 4 phr (parts per hundred rubber) EG22, the compound’s Mooney viscosity decreases significantly. Rheologically, this means a reduction in macroscopic viscosity, an increase in the proportion of linear molecular chains, and fewer entanglement points. This is not due to the dilution effect of traditional plasticizers but because EG22 breaks the three-dimensional physical network of fillers, releasing the trapped rubber phase, thus achieving excellent processing fluidity while maintaining high filler loading (embodied as Tire compound processing aid low Mooney viscosity).

- Payne Effect analysis: Strain sweep curves show that the Payne Effect (ΔG’) of the EG22 formulation is greatly weakened. The reduction in the Payne Effect is direct proof of the transformation of the filler network from a “continuous phase” to an “isolated phase”. The higher retention of G’ at high strains indicates that the filler can maintain a more stable structure under dynamic deformation, which is a prerequisite for low heat build-up and excellent dynamic performance, directly addressing “How to reduce Payne effect in tire tread“.

3.2 Breakthrough in Dynamic Performance: Direct Reflection of Interface Optimization

- 60°C tan δ (characterizing rolling resistance) reduced by 14%: The value of tan δ in the medium-high temperature region (~60°C) mainly reflects the viscous dissipation of the rubber matrix and the friction at filler-filler and filler-rubber interfaces. The significant reduction in this value directly proves that the optimized filler network with EG22 greatly reduces ineffective sliding and friction between filler agglomerates (through Chemicals improves Low Rolling Resistance), directing more energy to propel the vehicle forward rather than converting it into heat.

- 0°C tan δ (characterizing wet grip) increased by 11%: Near the glass transition temperature (Tg), the value of tan δ reflects the resistance to chain segment motion. The increase in this value indicates that the strong interfacial bonding constructed by EG22 enhances the restraint of fillers on rubber chain segments. Under high-frequency (~10 Hz) road excitations, the compound can generate greater viscous response, thereby improving the displacement ability with the road water film and achieving stronger wet grip (achieving Improve wet grip without sacrificing rolling resistance).

- Physics explanation for synergistic gain: The simultaneous optimization of these two parameters overturns conventional understanding. The internal logic lies in the shift in energy dissipation mechanisms—from random internal friction in the filler network (harmful dissipation, contributing to high rolling resistance) to controlled polymer chain segment relaxation (beneficial dissipation, contributing to high wet grip). EG22 guides energy dissipation where needed (0°C) and saves it where not needed (60°C) by strengthening interfaces.

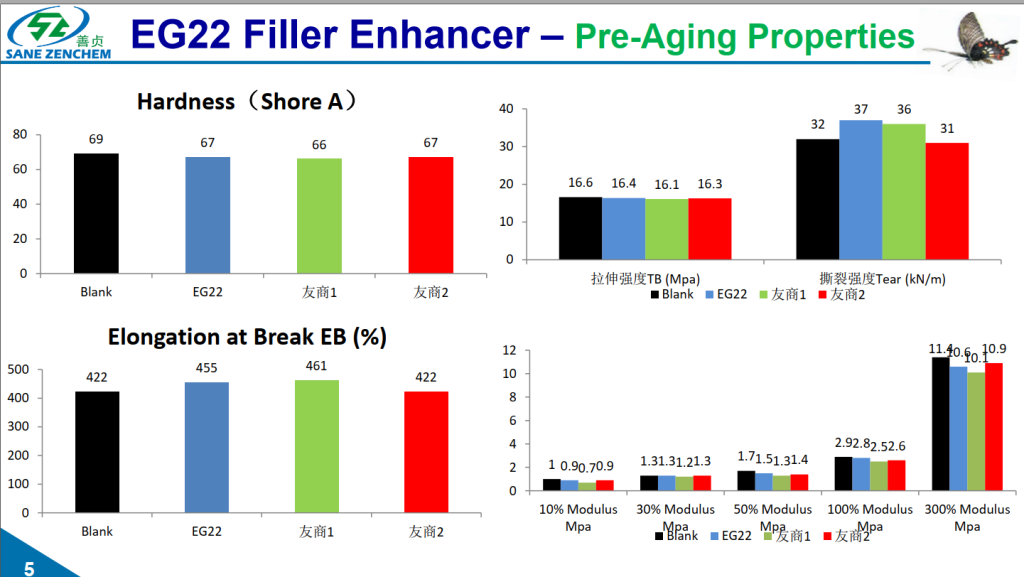

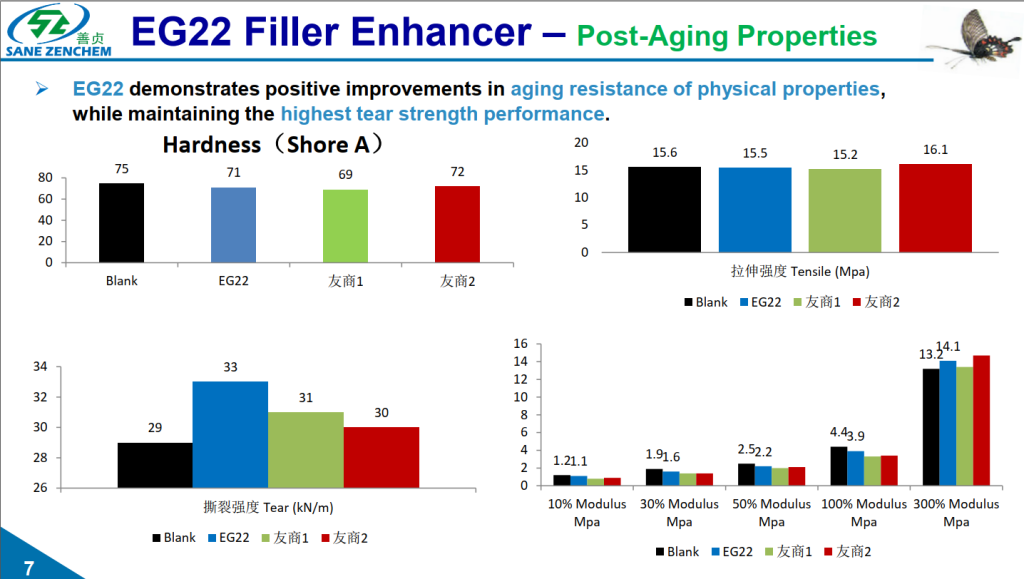

3.3 Cornerstone of Durability: Assurance of Mechanical and Thermal Properties

- Improvement in tear strength: The increase in tear strength is directly attributed to uniform stress distribution. The optimized filler network eliminates large agglomerates as stress concentration points, requiring external forces to overcome more chemical bonds (filler-rubber) to initiate crack propagation.

- Reduction in compression heat build-up: Under constant strain mode, the reduction in heat build-up is an inevitable result of the weak Payne Effect. The more stable filler network undergoes less destruction and reconstruction during cyclic deformation, reducing internal friction heat generation. This is crucial for the durability of tires, especially truck tires.

- Stability of wear performance: The stability in wear performance proves that EG22 does not destroy the continuity of the rubber matrix while improving other properties. Effective filler dispersion avoids aggravated abrasive wear due to agglomerate detachment, and strong interfacial bonding ensures effective resistance of rubber molecular chains during wear.

- Excellent aging retention: The high retention of tear strength after aging stems from lower initial heat build-up slowing the thermal aging rate and possibly the radical scavenging effect of EG22 molecules themselves, delaying polymer oxidative degradation. These results are verified through Dynamic mechanical analysis tire performance improvement.

4. Conclusion and Engineering Significance

This study, through a series of rigorous experimental data, demonstrates that Shanzhen Group’s EG22 Filler Enhancer (as an efficient Silica Reinforcement Enhancer y Chemical solution for Payne effect) achieves essential reconstruction of the silica filler network through its unique “catalytic silanization” and “spatial stabilization” mechanisms. Its technical value can be summarized at three levels:

- At the rheological level: It unifies low viscosity and high network stability in high-filler systems, resolving the contradiction between processability and reinforcement (serving as a Tire Filler Dispersion Agent).

- At the dynamic mechanical level: By optimizing energy dissipation paths, it achieves reduced hysteresis loss in the medium-temperature region and increased hysteresis loss in the low-temperature region, providing a clear physical model for simultaneously meeting low rolling resistance and high wet grip (achieving Improve wet grip without sacrificing rolling resistance).

At the materials engineering level: It endows the compound with a more uniform microstructure, comprehensively enhancing mechanical strength, fatigue resistance, and heat aging performance, and providing a reference for future applications of Bio based tire filler.

For tire engineers, EG22 offers a completely new, first-principles-based formulation design tool. It enables engineers to proceed from the core goal of “regulating the Payne Effect” for forward design, rather than repeated trial and error in the maze of performance contradictions. This technology not only points to a current Payne Effect Solution for the “magic triangle” but also opens new technical paths for developing higher-performance and more sustainable tire materials in the future.