In the rubber industry, the term “Carbon Black Dispersant” is often mentioned but rarely explored in depth. From a traditional perspective, dispersants are categorized as “Rubber Processing Aid“, their value confined to improving processes. However, based on in-depth research into filler-rubber interface science, we believe that superior dispersion is not an auxiliary process, but the core engineering task to unlock the full reinforcing potential of fillers and achieve a leap in product performance.

This article systematically explains how SaneZen Group New Materials elevates dispersion technology from an “art” to a predictable, controllable “science” through our GreenThinking® DP series products, delivering value beyond traditional understanding for our customers.

I. Deep Insight: The Nature and Multi-dimensional Cost of Poor Dispersion

The real technical challenge begins with the accurate diagnosis of the root cause.

- The Fundamental Contradiction in Silica Systems: The Trade-off between Reinforcement and Processability

Silica achieves reinforcement through its silanol (Si-OH) groups forming a hydrogen bond network. However, this same chemical characteristic leads to high bound rubber content and Mooney viscosity, creating the industry dilemma: “enhancing reinforcement makes processing difficult”. Traditional treatment agents often address one issue at the expense of another, either affecting cure or compromising physical properties. Therefore, finding a High Efficiency Dispersant specifically for silica is crucial. Many seek How to reduce Mooney viscosity in silica compounds, which points directly to the need for an effective Mooney Viscosity Reducer and a specialized Dispersante de sílice. - The Hidden Cost in Carbon Black Systems: Agglomerates and Defect Generation

Carbon black agglomerates are not only stress concentration points, reducing fatigue life, but also act as “nucleation sites” for bubbles and micro-defects in the compound. These defects propagate under dynamic loads, leading to premature product failure. Eliminating agglomeration is a prerequisite for enhancing product reliability and consistency, underscoring the importance of a high-performance Carbon Black Dispersant. - The Systemic Impact of the Efficiency Bottleneck

Mixing is the energy consumption focal point in rubber production. Poor dispersion directly leads to extended mixing cycles, soaring energy consumption, and creates a “flow bottleneck” for the entire production process (calendering, extrusion, molding), systemically capping the production capacity upper limit. Utilizing an Additive to reduce mixing energy consumption and a Compound Dispersing Agent or Rubber High Efficiency Dispersant becomes essential to Improve mixing efficiency.

II. Our Solution: Precision Interface Engineering Based on Molecular Design

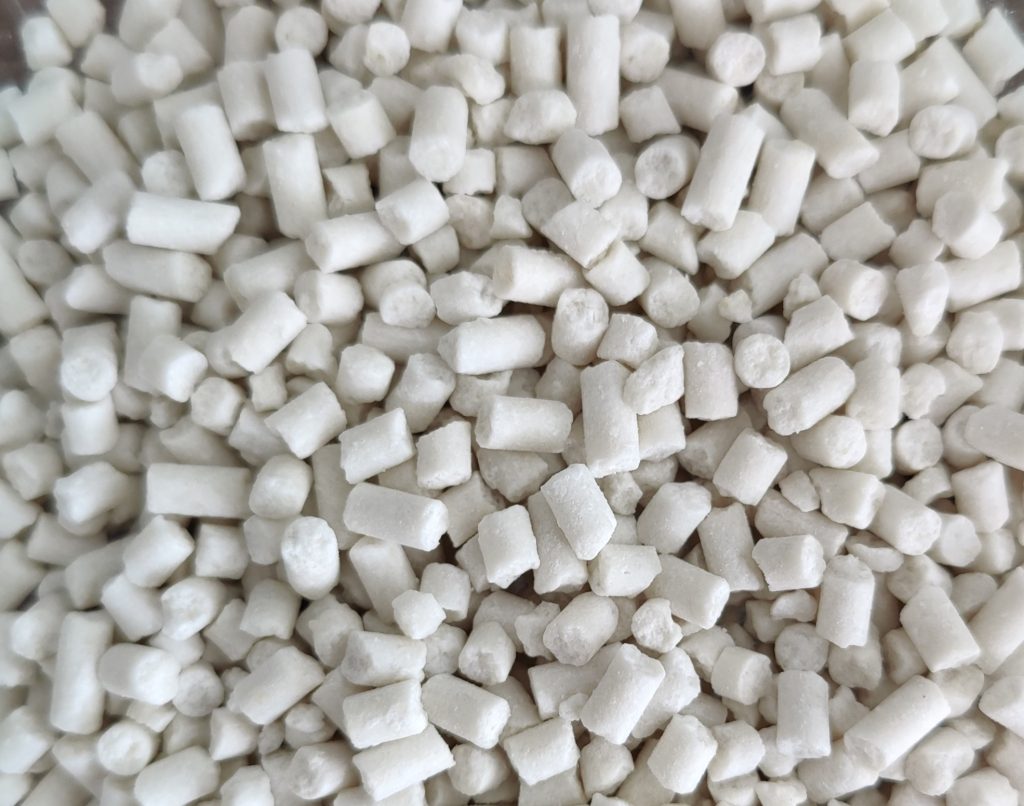

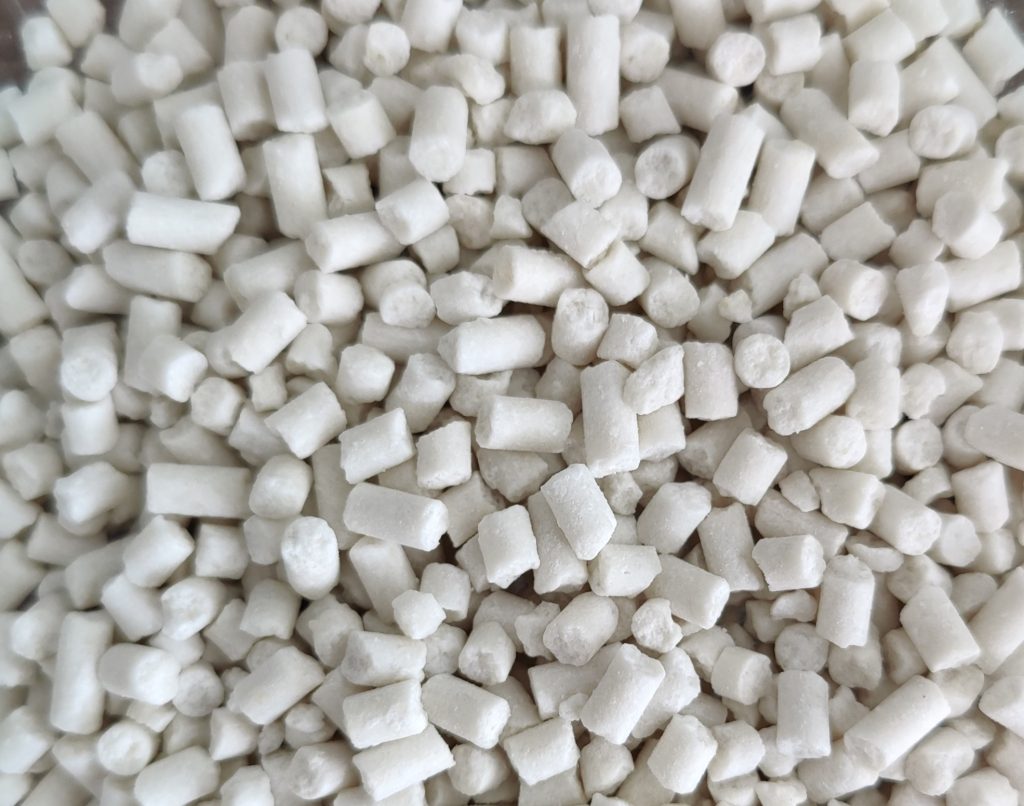

We do not aim to provide a “universal solution” but are committed to offering “specific targeted solutions” for different dispersion challenges.DP20W / DP25W: Chemical Decoupling Strategy for Silica Dispersion

- Technical Core: The molecular design of DP20W contains functional groups that can selectively react with the silanol groups on the silica surface. Its action is not simple physical isolation but fundamentally decouples the hydrogen bond network of silica by forming a stable chemical coating, granting the compound excellent flowability without sacrificing its reinforcing effect. This makes it a premier Dispersante de sílice.

- Propuesta de valor:

- Designed for high-performance silica-filled compounds: Particularly suitable for “green tire” tread compounds pursuing low rolling resistance and high wet grip, ensuring key dynamic mechanical properties (tan δ spectrum) are met while enabling processability.

- Guarantees interface adhesion: Its chemical properties ensure compatibility with the rubber matrix, having no negative impact on the adhesion between the compound and skeleton materials, resolving inherent deficiencies of many dispersants in this aspect.

DP86B: Physico-Chemical Synergy for Carbon Black Dispersion and Defect Control

- Technical Core: DP86B combines the ability to anchor onto carbon black surface functional groups with excellent surface activity. It reduces the surface energy of carbon black particles through encapsulation while simultaneously lowering the overall viscosity of the compound, synergistically achieving both “dispersion” and “bubble elimination” effects. It acts as an effective Carbon Black Dispersant and can contribute to the Method to eliminate rubber bubbles.

- Propuesta de valor:

- Optimized for industrial products pursuing reliability: In applications such as all-steel radial truck tires, conveyor belts, and hydraulic seals, its exceptional bubble-eliminating capability directly translates to lower product defect rates and higher sealing reliability.

- Performance empowerment: By achieving ultimate dispersion of carbon black, fully unlocking its reinforcing potential, simultaneous improvements in wear resistance, modulus, and flex resistance are often observed.

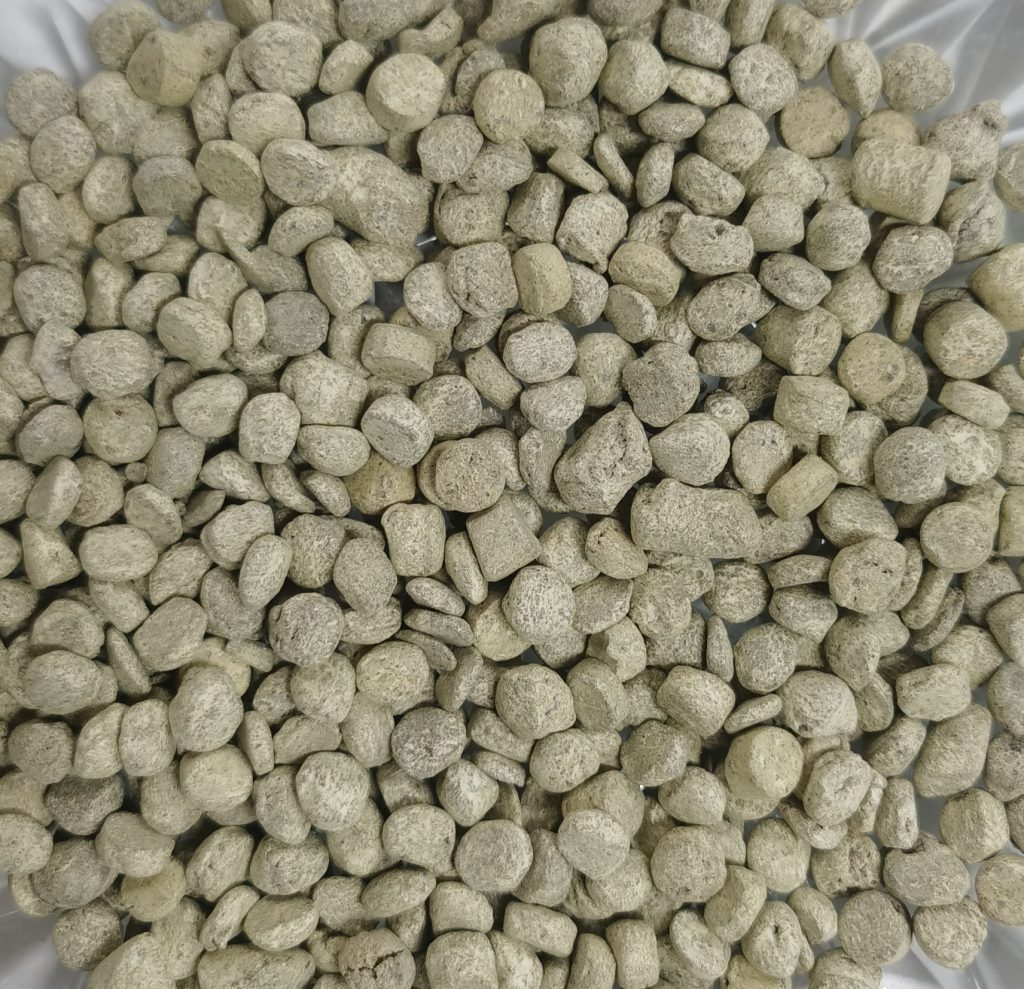

DP21 / DP26: Systemic Optimization of Processing Rheology

- Technical Core: These two are highly efficient internal lubrication systems that systematically optimize the compound’s rheological behavior by reducing friction between rubber molecular chains and at the filler-rubber interface. They are potent Mooney Viscosity Reducer options and key Aditivo de caucho for processing.

- Propuesta de valor:

- DP21: Suitable for extreme demands on appearance and efficiency. It provides unparalleled flowability and mold release for precision injection-molded products and high-surface-finish extruded products, directly enhancing product grade and production efficiency. It can also function as a Rubber surface brightening agent.

- DP26: Provides a reliable choice for cost-sensitive mass production. While maintaining core functionality, it offers better economy, making it a powerful tool for cost reduction and efficiency improvement in standardized products. It’s a versatile Rubber Processing Aid.

III. Evidence and Quantification: From Lab Data to Production Benefits

We understand that technical decisions must be based on credible data. The following case demonstrates the effect of DP20W in an NR/BR/SiO₂ tread compound:

| Indicador de resultados | Reference Formula | Reference Formula + 2.5 phr DP20W | Value Interpretation |

| Mooney Viscosity ML(1+4)100°C | 68 | 55 | Processing window significantly widened, extrusion surface quality improved |

| Payne Effect (ΔG’) | 1.85 MPa | 1.12 MPa | Filler network effectively broken, dispersion significantly improved |

| Mixing Time to Uniformity | 180 sec | 145 sec | Energy consumption reduced by ~20%, production capacity potential unlocked |

| Resistencia a la tracción | 22.5 MPa | 22.8 MPa | Key physical properties fully maintained |

| tan δ @60°C | 0.105 | 0.098 | Rolling resistance reduced, contributing to fuel economy |

Conclusion: DP20W systematically solves the processing challenges of silica compounds without compromising performance.

IV. Why Partner With Us: Driving Customer Success with Knowledge

Choosing SaneZen Group means you are selecting not just a supplier, but an R&D partner focused on rubber material science. As a specialized Aditivo de caucho y Environmental rubber dispersant manufacturer, we focus on:

- Depth over Breadth: We focus on the core area of filler dispersion and strive for excellence.

- Precision over Generality: Our product line is based on a deep understanding of different system mechanisms, providing targeted solutions. We can help you find a Dispersant to replace stearic acid or select the best Tire compound dispersant.

- Value over Price: We are committed to creating comprehensive value far exceeding the product price itself by enhancing your product performance and production efficiency.

- Transparency and Sharing: We are eager to share our research findings and technical insights to jointly promote industry technological progress.

V. Conclusion: Starting a Technical Dialogue on Efficiency and Performance

In today’s environment with dual pressures from raw material costs and environmental regulations, tapping internal potential through material innovation and process optimization has become a necessary path for companies to maintain competitiveness. The precision dispersion technology represented by the SaneZen Group DP series is a key lever on this path. We are a committed Rubber flow dispersant manufacturer y Silica dispersant supplier ready to assist.We invite you, who are equally committed to technological upgrading and value creation, to start a deeper dialogue. Let’s work together, based on your specific formulation system and process conditions, to jointly verify how the GreenThinking® DP series can empower your products and show you How to improve compound flowability.