NBR PVC Rubber Plastic Blends

NBR PVC Rubber Plastic Blends

NBR PVC Rubber Plastic Blends

NV rubber and plastic blend is a blend of nitrile rubber and PVC. The rubber compound is vulcanized and molded after the vulcanizing agent is added (the vulcanizing agent is selected according to the process requirements).

product details

Applications: NV rubber and plastic blend rubber has excellent properties such as oil resistance, high strength and high hardness, so it is suitable for manufacturing oil pipes, rubber pipes, wires and cables, sheaths, belts, soles, rollers and other products.

Special properties:

- Rapid calendering and extrusion and smooth surface

- The storage stability is good

- Excellent wear and tear resistance

- Excellent ozone & weather resistance

- Excellent grease and solvent resistance

- Excellent antistatic property

- Good low temperature resistance

- excellent in flame retardancy

Characteristics

| Product name | NV2355 | NV3355A | NV5090 |

| Type | NBR+PVC | ||

| B-AN% | 23 | 33 | 50 |

| ML 1+4@100℃ | 55±10 | 55±10 | 90±5 |

| Color | Yellow | Light yellow | White |

Vulcanization performance:1. Sulfur, overspeed thiuram accelerators TMTD and TETD, and sulfenamide accelerators are added.

2.Accelerator CZ and thiazole accelerator DM were vulcanized at 170 ℃ for 6 min.

Standard formula

| Name of raw material | NV2355 | NV3355A | NV5090 |

| Basic copy, phr | |||

| Rubber-plastic blend | 100 | 80 | 100 |

| Nitrile rubber | 20 | ||

| Carbon black reinforcing agent, N550 | 55 | 55 | 10 |

| Heavy calcium carbonate, 5-QY | / | 10 | / |

| Natural Gas Semi-Reinforcement, N770 | / | / | 55 |

| Silica, 136 | 5 | 10 | / |

| Plasticizer, DPHP | 20 | 25 | / |

| Plasticizer, ATBC | / | / | 30 |

| Zinc oxide, ZNO | 5 | 5 | 5 |

| Stearic acid, STA | 1 | 1.5 | 1.5 |

| Antioxidant, RD | 1 | 1 | 1 |

| Antioxidant, 4010 NA | 1.5 | 1.5 | 1 |

| Protective agent, paraffin | 2 | 1 | 3 |

| Internal release agent, 985P | 1 | 1.5 | / |

| Resin, HM601 | 2 | / | / |

| Vulcanizing agent, S-80 | 0.65 | 0.62 | / |

| Vulcanizing agent, MC-2 | / | / | 0.5 |

| Accelerator, TMTD | 1.2 | 1 | 0.9 |

| Accelerator, DM | 0.65 | 0.5 | / |

| Accelerator, TETD | / | / | 0.9 |

| Accelerator, CZ | 1.5 | 1.2 | 1.6 |

Product performance: NBR + PVC compound and vulcanized rubber

| Product name | NV2355 | NV3355A | NV5090 | ||

| Project | Test method | Unit | Classical value | ||

| Mooney viscosity (ML 1+4@ 100 ℃) | 42 | 35 | 31 | ||

| Sulfur change performance test: 180 ℃ × 5min × 1arc | |||||

| Minimum torque | ASTM D2048 | lb-in | 0.38 | 0.25 | 0.21 |

| Maximum torque | lb-in | 4.78 | 4.77 | 5.64 | |

| Scorch time TS2 | Sec | 77 | 77 | 59 | |

| Optimum vulcanization time TC90 | Sec | 114 | 116 | 111 | |

| 1. Mechanical properties 1.1 175 ℃ × 5 min after vulcanization | |||||

| Specific gravity | ASTM D297 | g/cm3 | 1.201 | 1.249 | 1.226 |

| Hardness (Shore A) | ASTM D2240 | Points | 65 | 65 | 55 |

| Tearing strength | ASTM D412 | Kg/cm2 | 11.56 | 12.41 | 14.84 |

| Elongation at break | % | 441 | 561 | 650 | |

| M100 | Kg/cm2 | 3.49 | 2.57 | 2.35 | |

| 1. Mechanical properties 1.2 changes in properties after aging at 100 ℃ for 70 hours | |||||

| Hardness (Shore A) Change | ASTM D2240 | Points | +8 | +5 | +5 |

| Change in breaking strength | ASTM D412 | % | -22.5 | -15.4 | -12.05 |

| Change in elongation at break | ASTM D412 | % | -24.5 | -20.75 | -20.74 |

| 2. Oil resistance 2.1 Performance change after aging in ASTM 901 oil at 100 ° C for 70 hours | |||||

| Hardness (Shore A) Change | ASTM D2240 | Points | +5 | +3 | +2 |

| Change in breaking strength | ASTM D412 | % | +5.75 | +3.29 | +1.07 |

| Change in elongation at break | ASTM D412 | % | -20.78 | -14.79 | -9.87 |

| Change in volume change rate | ASTM D471 | % | -10.24 | -4.28 | -2.08 |

| 2. Oil resistance 2.2 Performance change after aging in ASTM 903 oil at 100 ° C for 70 hours | |||||

| Hardness (Shore A) | ASTM D2240 | Points | -9 | -5 | -3 |

| Tearing strength | ASTM D412 | % | 7.78 | 10.08 | 12.89 |

| Elongation at break | ASTM D412 | % | 324 | 478 | 579 |

| Volume change rate | ASTM D471 | % | +25.8 | +19.54 | +14.78 |

| 2. Performance change of oil-resistant 2.3 after aging in fuel C at 40 ℃ for 48 hours | |||||

| Volume change rate | ASTM D471 | % | +38.89 | +34.23 | +30.69 |

| 3. The compression permanent deformation is 100 ℃ for 70 hours (the vulcanization condition of the sample used in the experiment meets 170 ℃ × 10 min). | |||||

| Deformation rate | ASTM D395 | % | 39.74 | 40.79 | 45.34 |

| 4. Ozone resistance 80pphm × 20% elongation × 40 ℃ × 120 hours | |||||

| Whether it is cracked | ASTM D1171 | / | No | No | No |

| 5. Low temperature retraction performance | |||||

| / | GB/T 7758 | ℃ | -48 | -42 | -43 |

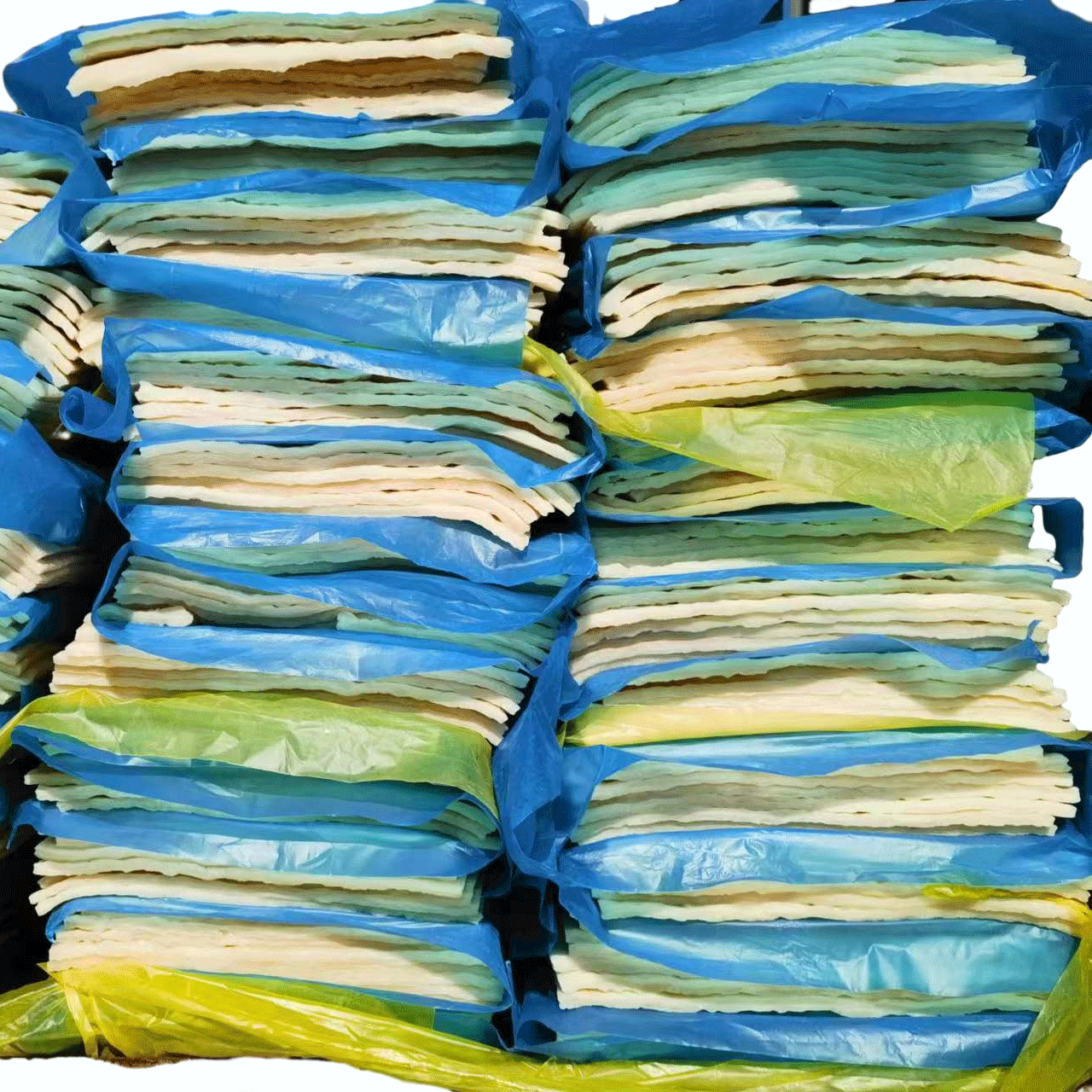

Packing: NBR + PVC rubber and plastic blend shall be packed and transported in 25 kg/carton.

Storage and shelf life :NBR + PVC rubber and plastic blends in unopened original packaging at a temperature below 40 ° C from the date of production indicated on the packaging .Keep for 18 months from the date of expiration.

For More Product Information, Please Visit Our Website: www.sanezenrubber.com

| Contact:

Plant Address: No.6, Xinqing Road, Xuanzhou North Economic Development Zone, Xuancheng City, Anhui Province Commercial Address: Room 1606-1608, Boda Commercial Buildings, No. 11 Puhuitang Road Xuhui District, Shanghai, China 200030 Tel: +86 21 6487 9251 Fax: +86 21 5106 2693 E-mail: yorichen@sanezen.com |

| Warning to the users:

The information contained in this document is given in good faith based on our current knowledge. It is only an indication and is in no way binding, particularly as regards infringement of or prejudice to third party rights through the use of our products. Sanezen guarantees that its products comply with its sales specifications. This information must on no account be used as a substitute for necessary prior tests which alone can ensure that a product is suitable for given use. Determination of the suitability of product for the uses and applications contemplated by users and others shall be the sole responsibility of users. Users are responsible for ensuring compliance with local legislation and for obtaining the necessary certifications and authorisations. Users are requested to check that they are in possession of the latest version of this document and Sanezen is at their disposal to supply any additional information. |

Poduct

Search by Product lines

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!