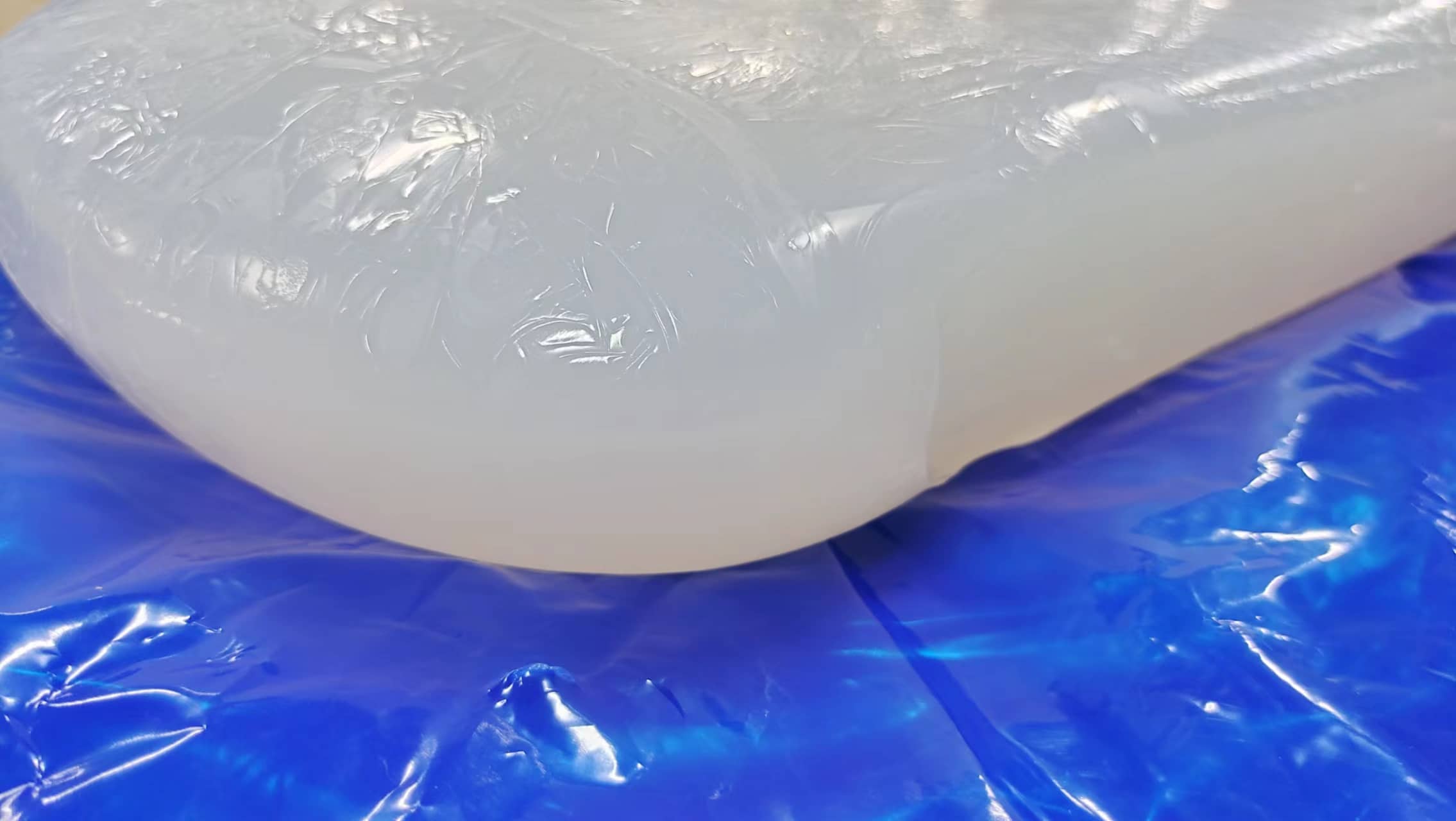

Oil Resistant Silicone Rubber Compound

Oil Resistant Silicone Rubber Compound

Oil Resistant Silicone Rubber Compound

Series of SR 2100 UOR are silicone rubber compounds which are vulcanization molding by adding curing agents. (The curing agents should be chosen according to process requirements.)

product details

The Sanesil® SR2100 UOR Series represents a premium line of silicone rubber compounds designed for vulcanization molding with tailored curing agents. As a leading Custom Silicone Rubber Manufacturer and Supplier, SANEZEN Group combines advanced material science with sustainable manufacturing to deliver high-performance solutions for demanding industrial applications.

These compounds excel in mechanical strength, thermal stability (up to 225°C), and oil resistance, making them ideal for Special Silicone Rubber applications requiring low compression set and durability. Whether for molding, injection, or extrusion processes, our Custom Silicone Rubber Factory capabilities ensure formulations meet precise client specifications.

Special properties:

- Excellent physical strength of raw rubber.

- Barely structured in a long-term storage.

- Low compression set.

- Good thermalstability, up to 225℃

- Excellent resistance to oil (low swelling).

- Being able to be mixed with other rubbers.

Main applications:

- SR2100 UOR series can be used to manufacture mechanical rubber goods which require low compression set and good oil resistance. This series is suitable for molding, injection, extrusion process.

Characteristics:

Type (according to GB/T 5576-1997)…………………………..MVQ

Natural color…………………………………………………………….White

Curing Condition:

After addition of 1.2% of 2.5-dimethyl bis -(tertiobutyl peroxy) 2.5-hexane (50%) and vulcanization for 5 min. at 175°C, with post curing at 200℃×4.

Mechanical properties:

| Item | Test Method | Unit | Technical date | |||

| SR2150UOR | SR2160UOR | SR2170UOR | SR2180UOR | |||

| 1 Mechanical properties,1.1after a single curing | ||||||

| Density | ASTM D792 | g/cm3 | 1.19 | 1.25 | 1.32 | 1.37 |

| Hardness

(Shore A) |

ASTM D2240 | 51 | 62 | 71 | 82 | |

| Tensile Strength | ASTM D412 | MPa | 7.8 | 7.5 | 8.2 | 8.5 |

| Elongation | ASTM D412 | % | 350 | 300 | 220 | 160 |

| Tear Strength (Crescent) | ASTM D 624 B | kN/m | 16 | 15 | 15.2 | 13.2 |

| 1 Mechanical properties,1.1after secondary curing | ||||||

| Hardness

(Shore A) |

ASTM D2240 | 52 | 62 | 72 | 83 | |

| Tensile Strength | ASTM D412 | MPa | 7.7 | 7.5 | 8.3 | 8.6 |

| Elongation | ASTM D412 | % | 320 | 280 | 190 | 150 |

| Tear Strength (Crescent) | ASTM D 624 B | kN/m | 15 | 14 | 15.3 | 13 |

| Compression Set

(22hr/177℃) |

ASTM D395

Method A |

% | 10 | 10.9 | 8.2 | 7.9 |

| 1 Mechanical properties,1.3 Performance changes after 70 hours of aging at 225℃ | ||||||

| Hardness

(Shore A) |

ASTM D2240 | 55 | 65 | 74 | 85 | |

| Tensile Strength | ASTM D412 | MPa | 7.1 | 6.5 | 6.4 | 6.84 |

| Elongation | ASTM D412 | % | 310 | 235 | 150 | 130 |

| 2 Oil resistance: 2.1 Performance changes after 70 hours of aging in ASTM 903 oil at 150℃ | ||||||

| Hardness

(Shore A) |

ASTM D2240 | 36 | 48 | 56 | 69 | |

| Tensile Strength | ASTM D412 | MPa | 3.5 | 3.8 | 5.7 | 6.3 |

| Elongation | ASTM D412 | % | 430 | 400 | 340 | 274 |

| Volume change rate | ASTM D 471 | % | 37 | 35 | 36 | 34 |

| 2 Oil resistance: 2.1 Performance changes after 70 hours of aging in ASTM 901 oil at 150℃ | ||||||

| Hardness

(Shore A) |

ASTM D2240 | 49 | 60 | 69 | 80 | |

| Tensile Strength | ASTM D412 | MPa | 6.7 | 6.8 | 7.5 | 7.4 |

| Elongation | ASTM D412 | % | 420 | 350 | 310 | 285 |

| Volume Change Rate | ASTM D 471 | % | 5.4 | 5.2 | 3.4 | 2.3 |

Packaging:20 kg per cardboard boxes.

Storage and shelf life:

SR2100 UOR series may be stored in its original unopened packaging at a temperature below 40°C for up to 12 months as from the date of manufacture.

For More Product Information, Please Visit Our Website: www.sanezenrubber.com

| Contact:

Plant Address: Baishou Road, North District of Xuan Zhou Economic Development Zone, Xuan Cheng City Anhui Province, China. Commercial Address: Room 1606-1608, Boda Commercial Buildings, No. 11 Puhuitang Road Xuhui District, Shanghai, China 200030 Tel: +86 21 6487 9251 Fax: +86 21 5106 2693 E-mail: yorichen@sanezen.com |

| Warning to the users:

The information contained in this document is given in good faith based on our current knowledge. It is only an indication and is in no way binding, particularly as regards infringement of or prejudice to third party rights through the use of our products. Sanezen guarantees that its products comply with its sales specifications. This information must on no account be used as a substitute for necessary prior tests which alone can ensure that a product is suitable for given use. Determination of the suitability of product for the uses and applications contemplated by users and others shall be the sole responsibility of users. Users are responsible for ensuring compliance with local legislation and for obtaining the necessary certifications and authorisations. Users are requested to check that they are in possession of the latest version of this document and Sanezen is at their disposal to supply any additional information. |

Poduct

Search by Product lines

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!