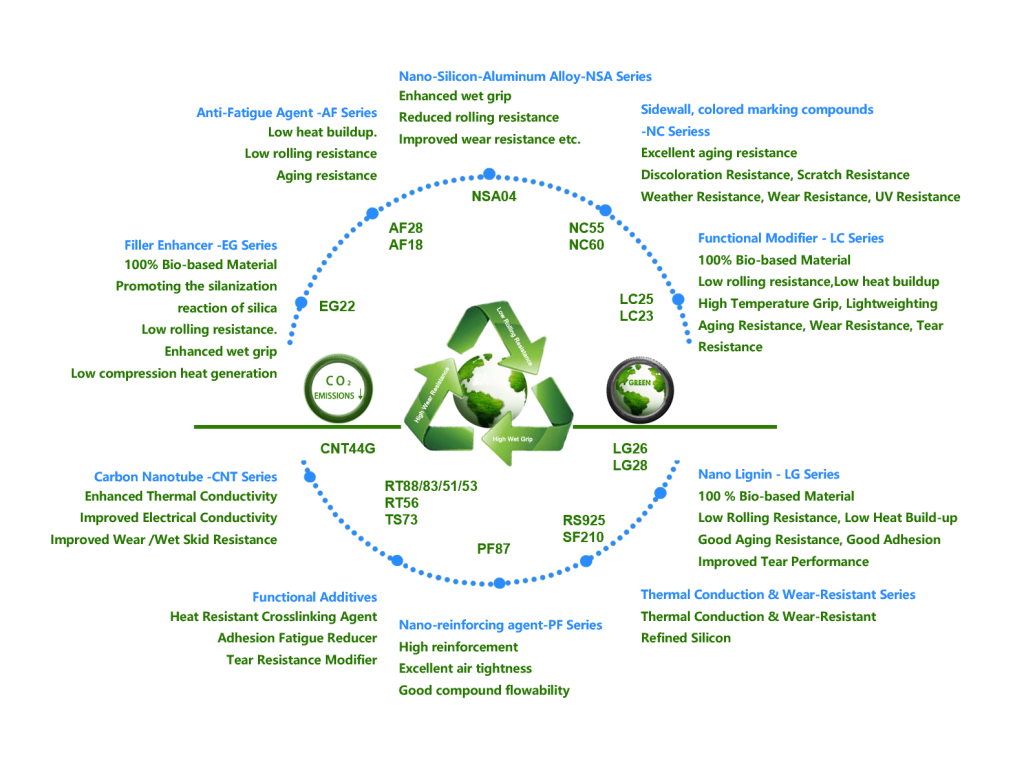

This article provides an in-depth interpretation of key experimental data on the impact of tire wear on vehicle performance, quantitatively analyzing the severe effects of tire wear on braking performance and noise, and systematically proposing Tire Wear Performance Solutions. Based on conclusive evidence of performance degradation, we analyze the material science roots and introduce Sane Zenchem’s Sustainable Tire Additive Solutions, including innovative materials such as EG22 bio-based filler enhancer, AF28 anti-fatigue agent, CNT44G carbon nanotubes, NSA04 nano silicon aluminum alloy, and LC series bio based modifiers. These materials aim to optimize the filler network, enhance wear resistance and wet grip, reduce heat buildup and rolling resistance, and improve aging resistance, providing tire manufacturers with a comprehensive, data- and material science-based solution that significantly improves Tire Lifecycle Performance Enhancement. Additionally, this article addresses industry concerns such as How to reduce tire wear and tear и Improve wet grip on worn tires, highlighting the leading role of Tire additive Suppliers China in technological innovation.

Chapter 1: Introduction——The Paradigm Shift from “New Tire Performance” to “Full Lifecycle Performance”

In the increasingly competitive tire industry, the race for performance indicators has extended from single “new tire condition” to the entire service life, which is the core of Tire Lifecycle Performance Enhancement. An excellent tire should not only perform outstandingly when leaving the factory but also maintain the stability of its key safety and performance characteristics after tens of thousands of kilometers of driving. However, reality often falls short of ideal, especially in achieving Wet Grip Rolling Resistance Balance. Through rigorous scientific experiments, we gain a valuable data perspective on this issue. The research goes beyond theoretical speculation, using actual road wear tests to accurately quantify the substantial impact of tire wear on vehicle performance, providing an empirical basis for Solutions for tire performance degradation.

This article will first present the core data from the study, revealing the harsh facts of performance degradation. Then, we will analyze the deep-seated mechanisms from a material science perspective. Finally, we will systematically introduce Sane Zenchem’s series of innovative additive solutions, which are designed to directly address the challenges revealed by the data, helping tire manufacturers achieve a strategic leap from “new tire performance” to “full lifecycle performance” and assisting companies in meeting the high standards of How to achieve EU Tire Label Grade A.

Chapter 2: Empirical Data Reveals——Quantitative Impact of Tire Wear on Performance

The study selected five brands (A-E) of 205/55R16 tires for approximately 21,000 km of actual road wear testing, comparing the performance of new and worn tires. The data clearly depicts a spectrum of performance degradation, directly related to the need for How to reduce tire wear and tear and the application of Advanced materials for tire durability.

2.1 Table 1 Wear Degree of Different Brand Tires at Various Wheel Positions

| Wheel Position | Initial Tread Depth (mm) | Worn Tread Depth (mm) | Wear Degree (%) |

| Brand A Tire | |||

| Left Front | 6.48 | 2.10 | 43.0 |

| Right Front | 6.46 | 2.07 | 42.6 |

| Left Rear | 6.43 | 1.12 | 23.2 |

| Right Rear | 6.51 | 1.27 | 25.9 |

| Brand B Tire | |||

| Left Front | 7.45 | 4.06 | 69.4 |

| Right Front | 7.49 | 4.06 | 68.9 |

| Left Rear | 7.61 | 2.02 | 33.6 |

| Right Rear | 7.55 | 2.24 | 37.6 |

| Brand C Tire | |||

| Left Front | 7.00 | 3.56 | 65.9 |

| Right Front | 6.90 | 3.25 | 61.3 |

| Left Rear | 6.90 | 1.72 | 32.5 |

| Right Rear | 6.94 | 2.03 | 38.0 |

| Brand D Tire | |||

| Left Front | 6.55 | 1.92 | 38.8 |

| Right Front | 6.51 | 1.89 | 38.5 |

| Left Rear | 6.57 | 0.90 | 18.1 |

| Right Rear | 6.60 | 1.04 | 20.8 |

| Brand E Tire | |||

| Left Front | 6.87 | 1.90 | 36.1 |

| Right Front | 6.88 | 2.00 | 37.9 |

| Left Rear | 6.92 | 0.94 | 17.7 |

| Right Rear | 6.91 | 1.04 | 19.6 |

Data Interpretation and Technical Challenges:

- Front tire wear is much higher than rear tires: All brands show that the front tires, as driving wheels, have nearly twice or higher wear than the rear tires. This indicates that the front tire compounds endure harsher driving, steering, and braking stresses, urgently requiring Tire Wear Performance Solutions.

- Significant differences in wear resistance: Under the same mileage, the front tire wear of brands B and C (~65-69%) is significantly higher than that of brands A, D, and E (~36-43%). This directly reflects huge differences in wear resistance and tear resistance among different formulations, highlighting the importance of Tire compound for lower rolling resistance и Cost effective tire compounding solutions.

Material Science Perspective: The essence of wear is the microscopic tearing and fall of rubber material under repeated stress from the road surface. Improving the tear strength, abrasion resistance (e.g., reducing DIN abrasion), and dynamic fatigue life of the tread compound is the core of solving this problem, which is also the focus of Advanced materials for tire durability R&D.

2.2 Reversal of Braking Performance: A Safety Concern

Table 3 Wet Braking Distance of New vs. Worn Tires for Different Brands

| Tire Brand | New Tire Braking Distance (m) | Worn Tire Braking Distance (m) | Performance Decay Rate |

| Brand A | 26.73 | 29.85 | +11.7% |

| Brand B | 27.23 | 29.37 | +7.9% |

| Brand C | 28.03 | 30.14 | +7.5% |

| Brand D | 27.56 | 30.42 | +10.4% |

| Brand E | 27.74 | 29.41 | +6.0% |

**Average decay rate approx. +8.7%**

Table 5 Dry Braking Distance of New vs. Worn Tires for Different Brands (Source: Research)

| Tire Brand | New Tire Braking Distance (m) | Worn Tire Braking Distance (m) | Change |

| Brand A | 37.86 | 36.75 | -2.9% |

| Brand B | 38.42 | 35.95 | -6.4% |

| Brand C | 38.33 | 35.78 | -6.7% |

| Brand D | 36.81 | 36.92 | +0.3% |

| Brand E | 41.20 | 38.37 | -6.9% |

Data Interpretation and Technical Challenges:

- Wet braking performance generally deteriorates: The wet braking distance of worn tires for all brands increases significantly, with an average increase of nearly 10%. This is a critical safety hazard, directly pointing to the urgent need for Improve wet grip on worn tires. The root cause is the reduced drainage capacity due to shallower tread patterns, but the deeper reason is that when the patterns cannot effectively drain water, the microscopic wet grip of the tread compound itself is insufficient to provide adequate friction.

- Complex changes in dry braking performance: The dry braking distance of most brands’ worn tires shortens, mainly due to increased contact area and possibly rougher surfaces after compound wear. However, this cannot be considered performance improvement but rather a manifestation of broken performance balance. The real challenge for formulators is how to extremely enhance wet grip without sacrificing dry braking, achieving Wet Grip Rolling Resistance Balance.

Material Science Perspective: Wet braking requires the compound to effectively puncture and drain the water film at the microscopic level, forming close contact with the road surface. This relies on the dynamic viscoelasticity of the compound, specifically represented by the tan δ value (loss factor) around 0°C to 10°C. A higher tan δ @ 0°C usually indicates better wet grip performance, which is also the direction of technological breakthroughs for Tire additive to prevent heat buildup и Bio based filler for tire manufacturing.

2.3 Continuous Decline in Noise Comfort

Tables 8-10 Interior Noise Level of New vs. Worn Tires at Different Vehicle Speeds [dB(A)]

| Tire Condition | 60 km/h | 80 km/h | 100 km/h |

| New Tires (Average) | 56.1 | 59.0 | 62.2 |

| Worn Tires (Average) | 56.5 | 59.7 | 63.7 |

| Noise Increase | +0.4 | +0.7 | +1.5 |

Data Interpretation and Technical Challenges:

- At all speeds, the interior noise of worn tires is higher than that of new tires.

- As speed increases, the noise gap between worn and new tires gradually widens. At 100 km/h, the average noise increase reaches 1.5 dB(A), a difference that occupants can clearly perceive.

- The reason is that after pattern wear, the pump effect and pipe resonance effect intensify, and the dynamic modulus and damping characteristics of the compound itself may change after long-term use, leading to increased vibration and noise. This requires material formulations to balance Solutions for tire performance degradation and comfort optimization.

Material Science Perspective: Optimizing the dynamic mechanical properties of the compound (e.g., modulus at different frequencies and strains) and improving filler dispersion to reduce the Payne effect help reduce the internal friction and vibration of the compound itself, thereby assisting in reducing tire noise, which is also a focus of Tire filler Manufacturers China и Bio Based tire filler Manufacturers China in R&D.

Chapter 3: Material Science Solutions to Address Challenges

Facing the three major challenges revealed by the data——wear resistance, wet braking safety, noise and comfort——Sane Zenchem believes that introducing precisely designed functional additives into the polymer composite system is key to breakthroughs. Our Sustainable Tire Additive Solutions system works synergistically from four levels: filler network optimization, polymer chain modification, nano-level enhancement, and interface functionalization, providing the industry with Tire Wear Performance Solutions и Cost effective tire compounding solutions.

3.1 Solution One: Optimizing the Filler Network, Laying the Foundation for High Performance

Goal: To establish a more efficient and stable filler-rubber matrix foundation platform for improving various performances. This is crucial for high-fill silica/carbon black systems and reflects the technological innovation of Tire additive Suppliers China.

- Core Technology: GreenThinking® EG22 Bio-Based Filler Enhancer

- Mechanism: EG22 is a silane reaction promoter specifically designed for high-filler compounds. It significantly improves the degree and efficiency of the silanization reaction of silica and other fillers. This means:

- Better dispersion: Promotes rapid incorporation and dispersion of fillers, reducing mixing energy consumption, and forming a more homogeneous composite system.

- Significantly reduced Payne effect: Reduces the formation of filler networks, making the compound’s modulus more stable under different strains, which is crucial for dynamic heat buildup and handling.

- Enhanced interface bonding: Improves reinforcement and dynamic performance by enhancing the coupling between fillers and rubber.

- Data Support:

- In the same formulation, adding 4phr EG22 can significantly reduce Mooney viscosity, improving processability.

- RPA strain sweep shows that EG22 can greatly reduce the Payne effect, indicating greatly improved filler dispersion.

- Dynamic performance analysis (DMA) proves that EG22 achieves the optimal combination of wet grip improvement (11%) and rolling resistance reduction (14%), directly contributing to How to achieve EU Tire Label Grade A.

Application Value: EG22 is the “cornerstone” for building high-performance tread compound formulations. It first optimizes the state of the most critical component—filler—from the root, creating an ideal environment for subsequent products like AF28 and NSA04 to exert their maximum effects, making it one of the core technologies for Tire Lifecycle Performance Enhancement.

- Mechanism: EG22 is a silane reaction promoter specifically designed for high-filler compounds. It significantly improves the degree and efficiency of the silanization reaction of silica and other fillers. This means:

3.2 Solution Two: Comprehensively Improving Wear Resistance and Mechanical Property Retention

Goal: To address the severe wear shown in Table 1, especially the high wear rate of front tires, extend tire service life, and directly respond to market demands for How to reduce tire wear and tear.

- Core Technology: GreenThinking® CNT44G Highly Dispersed Multi-Walled Carbon Nanotubes

- Mechanism: CNT44G can more effectively form a three-dimensional nano-enhancement network in the filler-rubber matrix optimized by EG22. Its extremely high tensile strength (about 100 times that of steel) and aspect ratio greatly enhance the compound’s tear strength, modulus, and wear resistance. This nano-scale fiber network effectively prevents the propagation of micro-cracks, thereby delaying the wear process.

- Synergistic Effect: CNT44G also has excellent thermal conductivity, helping to dissipate heat generated during wear, avoiding accelerated wear due to thermal softening, embodying the function of Tire additive to prevent heat buildup.

- Auxiliary Technology: GreenThinking® LC Series Bio-Based Functional Modifiers

- Mechanism: The LC series mainly consists of modified nano-lignin and nano-cellulose. Their natural rigid aromatic ring structure and porous characteristics provide reinforcement while partially replacing carbon black, achieving lightweight. Their active functional groups enhance rubber-filler interaction, further improving tear strength and cut resistance.

- Data Support: In application experiments, LC series products can increase tear strength by 10-40% and positively contribute to wear resistance, serving as a model for Bio based filler for tire manufacturing.

Application Value: Introducing CNT44G and the LC series into tread compounds, especially for front tire formulations, can directly address the high wear problems shown by brands B and C, flattening the wear curve, achieving longer service life and more stable contact patterns, representing a comprehensive embodiment of Advanced materials for tire durability.

3.3 Solution Three: Fundamentally Improving Wet Braking Safety

Goal: To overcome the industry challenge of significantly increased wet braking distance of worn tires shown in Table 3, achieving a safety breakthrough in Improve wet grip on worn tires.

- Core Technology: GreenThinking® NSA04 Nano-Silicon-Aluminum Alloy

- Mechanism: NSA04 is a functional material that revolutionarily reacts with silane coupling agents during vulcanization to form hard Al-O-Si bond compound particles. These uniformly dispersed nano-scale hard particles act as “micro-anchors” on wet roads, effectively puncturing the water film between the tire and the road surface, greatly enhancing the microscopic wet grip of the compound itself.

- Data Support:

- In PCR tread formulations, adding 12.5 phr NSA04 can increase tan δ @ 0°C (wet grip indicator) by 8.3%-10.3%.

- Crucially, it simultaneously reduces tan δ @ 60°C (rolling resistance indicator) by 10.4%-11.6%, breaking the “magic triangle” of performance and achieving Wet Grip Rolling Resistance Balance.

- Correlation with the Study: Even when the pattern is worn and drainage capacity decreases, the tread compound containing NSA04 can rely on its excellent microscopic grip to provide braking performance far exceeding traditional compounds, directly compensating for the performance loss due to reduced pattern depth, making it a key technology for Solutions for tire performance degradation.

3.4 Solution Four: Maintaining Low Rolling Resistance and High Durability

Goal: Although not directly measured in the study, heat buildup and increased rolling resistance are inevitable results of tire wear. The combination of EG22, AF28, and CNT44G provides a multi-level solution, focusing on Tire compound for lower rolling resistance и Tire additive to prevent heat buildup.

- Core Technology: GreenThinking® AF28 Anti-Fatigue Agent

- Mechanism:

- Reduce hysteresis heat buildup: AF28 molecules can cap the ends of natural rubber molecular chains, reducing chain segment friction, fundamentally reducing dynamic heat buildup.

- Inhibit reversion: It stabilizes polysulfidic crosslinks, preventing network structure degradation due to high temperatures during long-term use, thereby maintaining modulus and hardness, extending service life.

- Data Support: Adding 1.0 phr AF28 can significantly reduce compression heat buildup by about 30%, and reduce rolling resistance (tan δ @ 60°C) by 18.4%, contributing to How to achieve EU Tire Label Grade A.

- Mechanism:

- Synergy with EG22 and CNT44G:

- EG22 contributes to reducing rolling resistance by lowering the Payne effect.

- AF28 reduces heat buildup from the chemical level.

- CNT44G enhances heat dissipation from the physical level.

The synergy of the three constitutes a comprehensive guarantee from the filler network to the polymer chain to thermal management, ensuring that the tire maintains excellent fuel/electric energy efficiency and resistance to thermo-oxidative aging throughout its lifecycle, serving as a model for Cost effective tire compounding solutions.

Chapter 4: Building Future-Oriented Tire Formulation Strategies: Integration of Data and Materials

Based on the interpretation of research data and analysis of solutions, we propose the following systematic formulation design recommendations, integrating Tire Wear Performance Solutions, Tire Lifecycle Performance Enhancement, и Sustainable Tire Additive Solutions:

| Performance Dimension | Core Challenge (Data Revealed) | SaneZen Solution | Expected Outcome |

| Foundation Platform | Poor filler dispersion, high Payne effect, unreleased performance potential | EG22 Bio-based Filler Enhancer | Optimizes filler network, improves dispersion, reduces rolling resistance and heat buildup, laying the foundation for high performance. |

| Wear Life & Durability | Extremely high front tire wear rate (>60%), significant variation between brands (Table 1) | CNT44G + LC Series | Improves tear strength and wear resistance, flattens the wear curve, extends service life. |

| Safety Performance | Average increase in wet braking distance for worn tires >8% (Table 3) | NSA04 | Enhances the intrinsic wet grip of the compound, compensating for performance loss after tread wear. |

| Energy Efficiency / Durability | (Implicit challenge) Heat buildup leads to increased rolling resistance and accelerated aging | AF28 + EG22 + CNT44G | Multi-level, multi-mechanism synergy to minimize hysteresis heat generation, inhibit reversion, and maintain low rolling resistance throughout the lifecycle. |

| Comfort | Noise of worn tires increases significantly with speed (Tables 8-10) | EG22-led system-wide optimization of filler dispersion | Reduces Payne effect, optimizes dynamic modulus, helping to suppress noise increase. |

Formulation Application Guidelines:

- EG22: Add in the first mixing stage, dosage 2-5 phr, as the core for optimizing the filler network.

- NSA04: Add in the first mixing stage, used together with silane coupling agent and EG22, dosage 10-30 phr.

- AF28: Must be added in the first mixing stage together with NR, dosage 1~1.6 phr.

- CNT44G: Add in the first mixing stage, recommended dosage 3-6 phr.

- LC Series: Add in the first stage together with silica/carbon black, dosage 5-30 phr.

These guidelines reflect the practical experience of Tire filler Manufacturers China и Bio Based tire filler Manufacturers China in formulation optimization, providing technical support for Tire additive Suppliers China.

Chapter 5: Conclusion

The research on the impact of tire wear on vehicle performance tells us with irrefutable data that tire performance lifecycle management is a core issue related to safety, efficiency, and user experience. The wear differences in Table 1, the wet braking degradation in Table 3, and the noise that worsens with speed collectively point to deficiencies in tire formulation technology regarding durability and performance retention, urgently requiring Tire Wear Performance Solutions и Tire Lifecycle Performance Enhancement.

Sane Zenchem’s series of innovative products——EG22, AF28, CNT44G, NSA04, LC series——constitute a hierarchical, synergistic systematic technology toolbox. EG22 serves as the cornerstone, optimizing the entire filler-rubber composite system foundation; CNT44G and LC series provide extreme physical enhancement and sustainable solutions; NSA04 specifically tackles the safety pain point on wet roads; and AF28 guards the tire’s durability and energy efficiency from the molecular level. They work together from different dimensions, providing tire engineers with comprehensive and powerful weapons to address full lifecycle performance challenges, representing an outstanding example of Sustainable Tire Additive Solutions.

In the electric vehicle era, requirements for low rolling resistance and durability are becoming more stringent; in the global market, standards for safety performance are increasingly elevated. By adopting Sane Zenchem’s data- and material science-supported solutions, tire manufacturers will be able to create next-generation tire products that not only lead in the new tire stage but also continuously win consumer trust throughout their entire lifecycle, while achieving strategic goals such as How to achieve EU Tire Label Grade A и Cost effective tire compounding solutions.