Based on the experimental findings from the “Study on the Influence of Service Conditions on the Wear Characteristics of Nitrile Rubber Vulcanizates,” this paper deeply analyzes the mechanisms by which harsh operating conditions such as rotational speed, rotation angle, and load exacerbate the wear volume and surface damage of Nitrile Rubber (NBR). Research confirms that traditional NBR formulations have performance boundaries under dynamic loading. To break through this limitation, Anhui Shengxin, as a professional NBR/PVC rubber blends Manufacturers China, proposes high-performance NBR/PVC rubber-plastic blends as an upgrade solution. This article focuses on how this material series, through its unique polymer system, significantly improves wear resistance, mechanical strength, and anti-aging properties while maintaining the excellent oil resistance of NBR. It provides a reliable High wear resistance NBR material selection guide and material selection direction for engineers facing premature wear of rubber components and searching for Wear-resistant NBR rubber solutions или High load resistant rubber material, aiming to achieve effective Rubber parts lifespan improvement methods.

1. Introduction: From Laboratory Phenomenon to Engineering Reality

Nitrile Rubber (NBR) has become a core material for oil seals, oil pipes, rubber rollers, and various oil-resistant gaskets due to its exceptional oil resistance. However, in practical applications, especially under harsh conditions such as high-speed rotation, large angle deflection, or high load, NBR products often suffer from premature wear, tearing, surface roughening, and even failure, seriously affecting equipment operational reliability and service life. This is the fundamental reason many engineers search for How to solve NBR rubber wear under high speed и How to improve dynamic wear performance of nitrile rubber.

Recent research on the influence of service conditions on the wear characteristics of NBR vulcanizates has revealed the intrinsic root of this problem through systematic experimental data. The study clearly states: As rotational speed, angle, and load increase, the wear volume of NBR vulcanizates increases significantly, the wear surface morphology becomes increasingly complex, and surface roughness deteriorates sharply.

This conclusion sounds an alarm in the engineering field: when application conditions become severe, traditional NBR formulations may have reached their performance ceiling. So, where is the key to solving the problem? Anhui Shengxin believes the answer lies in material innovation. Leveraging profound rubber compound development experience and acting as a reliable Пользовательские резиновые смеси производителей Китай, we have launched the NBR/PVC rubber plastic blend series, designed to fundamentally empower NBR to calmly meet severe wear challenges.

2. Academic Research Reveals: How Harsh Conditions “Damage” NBR

To define the problem accurately, we first need to understand the core findings of the aforementioned research. This is crucial for developing effective Rubber tearing solution under high load conditions или How to prevent surface roughening of rubber components.

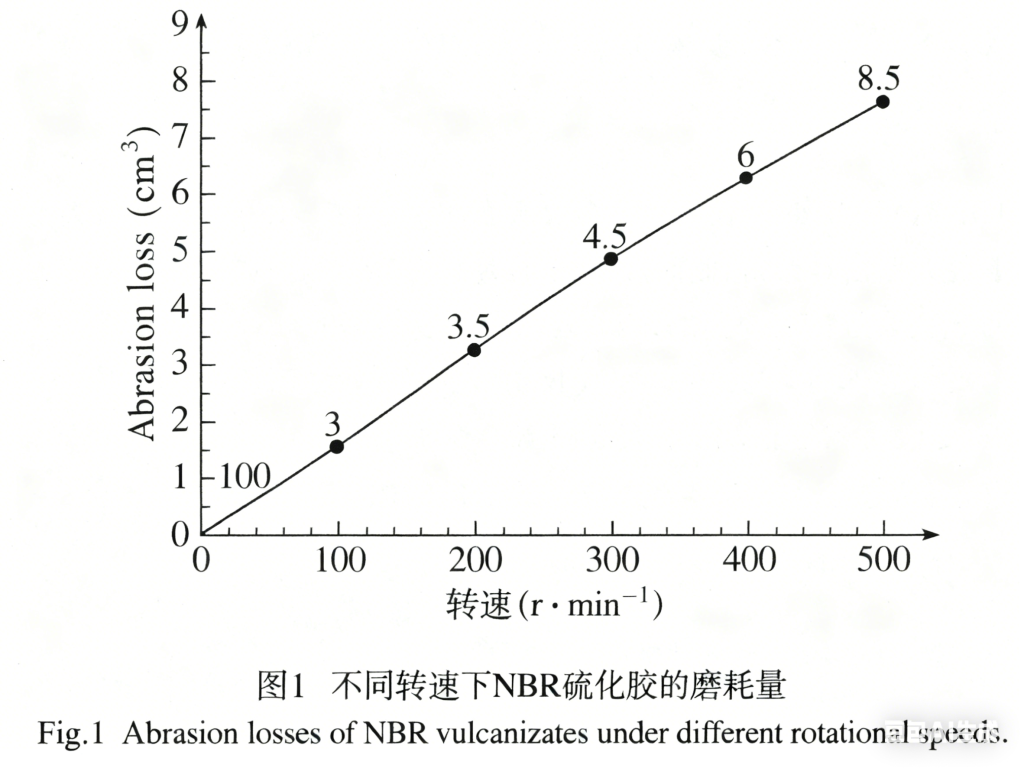

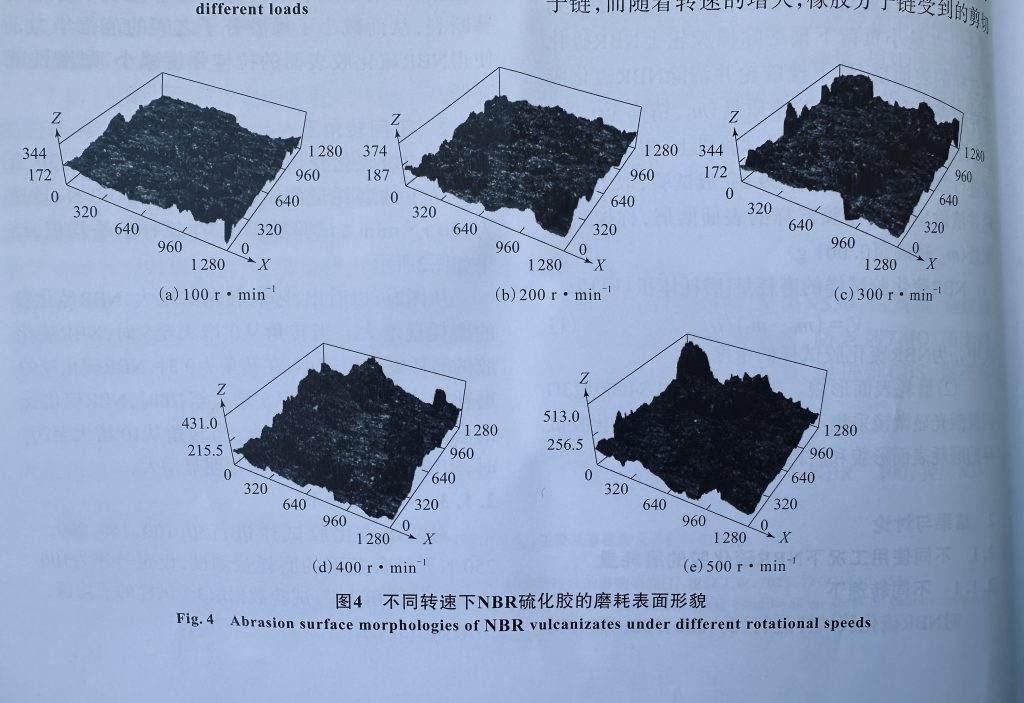

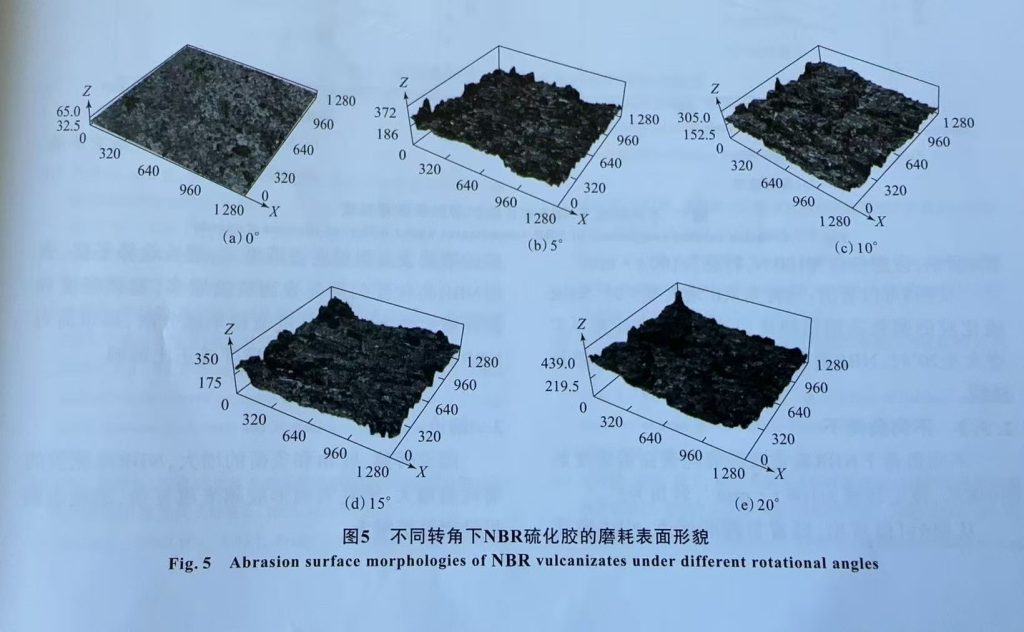

- Impact of Rotational Speed: When the speed increased from 100 r·min⁻¹ to 500 r·min⁻¹, the wear volume of NBR increased substantially. The research indicates that frictional heat generated by high speed activates rubber molecular chains and destabilizes the cross-linked structure, leading to decreased material strength and a sharp reduction in wear resistance. Laser microscope images show that the NBR wear surface under high speed exhibits numerous “protrusion-shaped” tear-like damages.

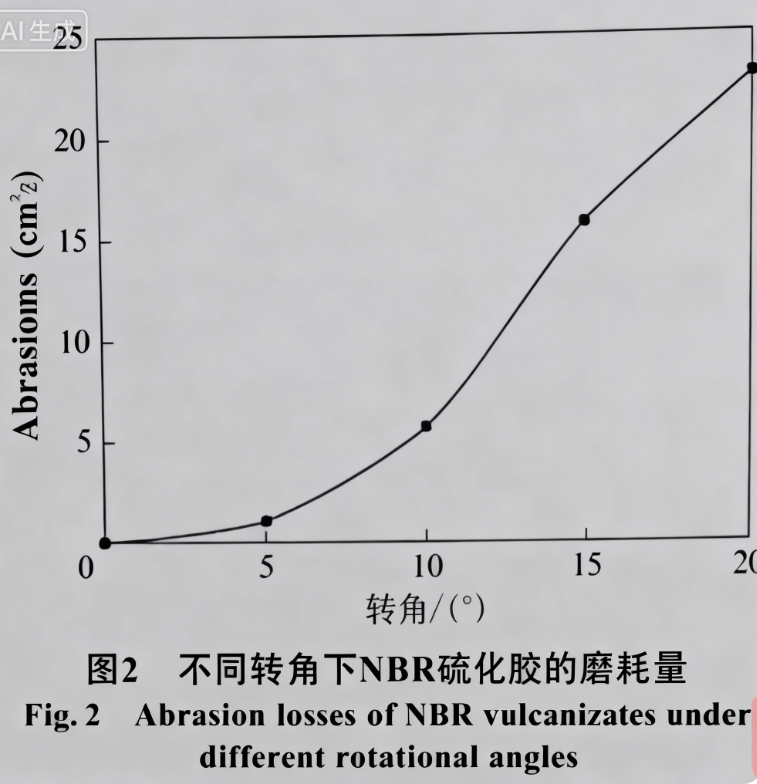

- Shear from Rotation Angle: An increase in the rotation angle exacerbates shear slip wear on the material surface. Even when the angle increased from 5° to 10°, a significant jump in wear volume was observed. This shear action directly damages the material surface, forming gully-like wear.

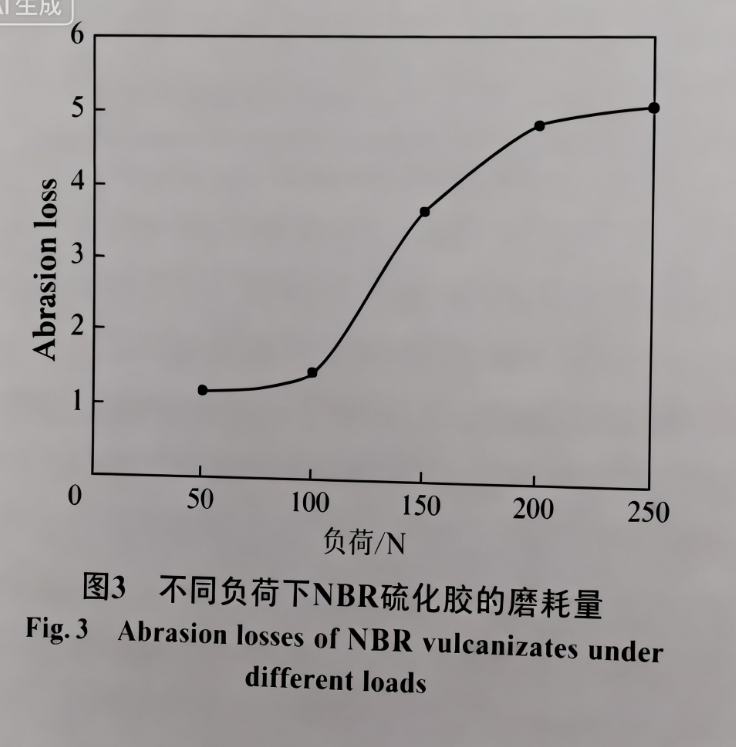

- Pressure from Load: An increase in load directly raises the contact pressure, leading to an increase in wear volume. In the medium load range of 100N to 200N, the growth in wear volume was most significant, indicating severe fatigue wear and abrasive wear occurring within this range.

NBR Wear Volume and Surface Morphology Changes under Different Conditions :

Core Pain Point Summary: This research clearly points to one conclusion—under dynamic, high-energy wear conditions, the inadequacy of pure NBR compound in terms of heat accumulation, tear resistance, and dynamic modulus retention capability is the main cause of its early failure. This directly fuels the market’s urgent need for Oil resistant and aging resistant rubber material recommendation.

3. Solution: Why is NBR/PVC Blend a Better Choice?

Facing the above pain points, simply adjusting the extender oil or carbon black in the NBR formulation often yields limited improvement. Anhui Shengxin’s approach is: By introducing PVC (Polyvinyl Chloride) to blend with NBR at the polymer chain level, constructing a brand new “rubber-plastic alloy” system. As an experienced NBR/PVC rubber blends Suppliers China, we provide comprehensive solutions.

3.1 Core Advantages of NBR/PVC Blends

- Exceptional Wear Resistance and High Strength: PVC is a rigid polymer. After blending with NBR, it significantly improves the compound’s modulus, tensile strength, and tear strength. This means that under the same load and speed, the NBR/PVC compound can better resist deformation and effectively suppress the embedding and cutting of abrasive particles, thereby exhibiting superior wear resistance. This is one of the best answers to How to choose more wear resistant rubber for high abrasion. Our NV3355A grade achieves a tensile strength of 12.41 Kg/cm², providing a solid matrix to resist complex wear.

- Excellent Anti-Aging and Ozone Resistance: PVC itself has excellent ozone and weather aging resistance. Introducing it into NBR fundamentally solves the persistent problem of cracking pure NBR products face in outdoor or ozone-rich environments. This is crucial for rubber components working in harsh environments.

- Smooth Processability and Good Surface Quality: The addition of PVC gives the compound better dimensional stability and surface smoothness during calendering and extrusion. A smooth and dense surface is itself the first line of defense against wear.

- Adjustable Hardness and Wide Adaptability: By adjusting the formulation, we can provide a series of products from low to high hardness. For example, NV2355 and NV3355A have a hardness of 65±5, suitable for applications requiring support; while NV5090 has a hardness of 55±5, combining flexibility and wear resistance, suitable for scenarios with dynamic bending requirements. Understanding the NBR PVC blend effect on oil seal performance can aid in better selection.

3.2 Data Comparison: How Sane Zenchem’s factory Anhui Shengxin rubber NBR/PVC Addresses Research Pain Points

Let’s correlate the product performance data with the pain points revealed by academic research, which is essentially a practical High wear resistance NBR material selection guide:

- Combating High Speed (Heat Buildup & Strength Loss):

- NV3355A, after heat air aging at 100°C × 70 hours, shows a hardness change of only +5 and a tensile strength change rate of only -15.4%. This demonstrates its excellent thermal stability, enabling it to better withstand temperature rise from high speed and maintain performance stability, effectively addressing the challenge of How to solve NBR rubber wear under high speed.

- Combating Large Angle & High Load (Tear Resistance & High Modulus):

- The 300% Modulus (M100) of NV2355 is 3.49 MPa, higher than many traditional NBR formulations. This indicates it possesses a higher modulus, resulting in less deformation and stronger tear resistance when subjected to shear force and high load, effectively suppressing the generation of complex wear surface morphology, providing the material basis for a Rubber tearing solution under high load conditions.

- Comprehensive Fluid Resistance Assurance:

- Data such as volume change rate and strength change rate after immersion in ASTM #1 oil and #3 oil are excellent, ensuring that the material does not soften or suffer strength degradation due to excessive swelling during long-term work in oil environments, thereby maintaining stable wear performance.

4. Sane Zenchem’s factory Anhui Shengxin rubber: Your Reliable High-Performance Rubber Material Partner

Choosing a material means choosing the R&D strength and quality assurance behind it. Anhui Shengxin’s mixing plant is not only a producer but also a partner in tackling challenges on the path of new material application. As a leading Пользовательские резиновые смеси Поставщики Китай и NBR/PVC blend manufacturer, we are committed to providing solutions that best meet your needs.

- Specialized Product System: We possess an independent R&D and production platform for rubber-plastic blends, deeply understanding the compatibility principles and process keys of NBR and PVC, ensuring excellent consistency and stability in every batch of products.

- Strong Custom Development Capability: We understand that “there is no best formula, only the most suitable one.” In addition to standard grades like NV2355, NV3355A, NV5090, we can provide customized NBR/PVC blend formulations based on your specific conditions—whether higher speed, special media, or extreme temperatures—precisely matching your requirements.

5. Conclusion

Cutting-edge academic research has sounded the alarm: the wear problem of traditional nitrile rubber under harsh conditions cannot be ignored. The solution lies in seeking answers from material science. For customers seeking How to improve rubber seal wear resistance in harsh conditions, our materials provide a clear technical path.

Sane Zenchem’s factory Anhui Shengxin rubber’s NBR/PVC rubber plastic blend series, by perfectly combining the elasticity and oil resistance of NBR with the rigidity, wear resistance, and aging resistance of PVC, successfully expands the performance boundaries of nitrile rubber. It is not only a “reinforced NBR” for high-wear conditions but also a strategic material that helps your products build a durability advantage in the fierce market competition. When you consider How to choose more wear-resistant rubber for high abrasion, Sane Zenchem’s factory Anhui Shengxin rubber should be your partner of choice.

When your products face the challenge of wear, Sane Zenchem’s factory Anhui Shengxin rubber is willing to provide you with full support from material selection to formula customization with our professionalism and dedication.