Breaking through the limitations of traditional additives, driving the green upgrade of the rubber industry with molecular-level innovation.

The Green Challenges of the Rubber Industry and Material Innovation

Driven by the global dual trends of carbon neutrality and electrification, the rubber industry is facing unprecedented pressure to upgrade. “Green tires” demand lower rolling resistance to improve energy efficiency, while “long-life products” require materials with excellent anti-fatigue and heat aging resistance. Traditional material formulations are approaching their performance limits, urgently calling for an innovative solution starting at the molecular level.

The AF Series high-performance anti fatigue agents (AF27, AF28), launched under the SaneZen Group, are groundbreaking rubber chemicals developed based on the concept of Molecular Interface Engineering. They are not simple processing aids but functional materials that fundamentally reshape the microstructure of rubber-filler composites through precise chemical coupling, providing manufacturers with a low-carbon path to high performance and sustainable production.

I. Core Technology Mechanism: How Molecular Interface Engineering Works

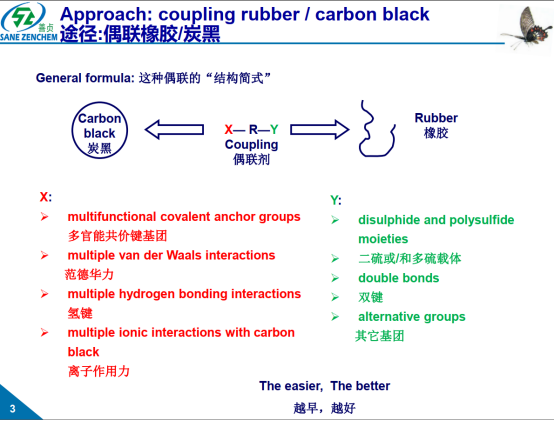

The core technology of the AF Series anti fatigue agents lies in their unique bifunctional group structure, acting like a “molecular bridge.” One end anchors onto the carbon black surface, while the other end chemically reacts with the rubber molecular chains, significantly enhancing the interfacial bonding strength.

- Solving the Century-Old Problem of Carbon Black Dispersion

Carbon Black (CB) is key to rubber reinforcement, but its surface-rich active sites (e.g., carboxyl, phenolic, quinone groups) are prone to agglomeration, leading to uneven dispersion. This is a primary root cause of high dynamic heat build-up and short fatigue life. - Precise Chemical Coupling Action

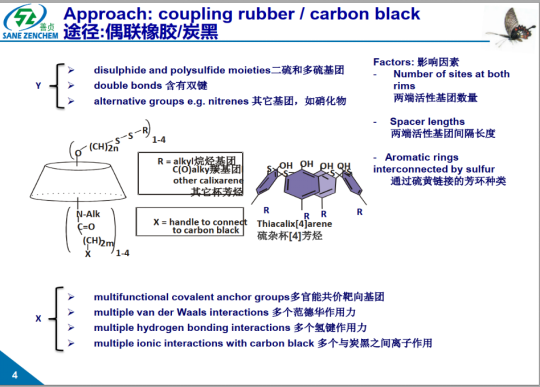

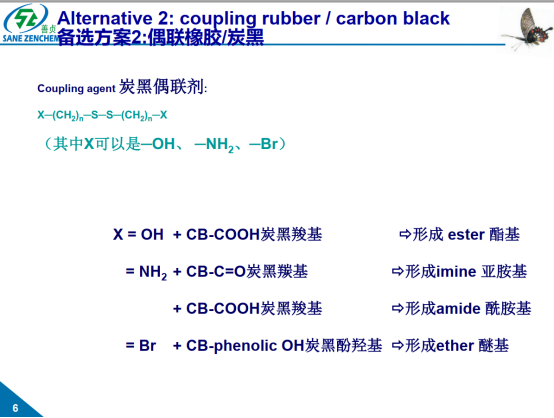

As shown in the technical documentation, the molecular design of AF anti fatigue agents precisely matches the chemical properties of carbon black and rubber:

X-end: Contains various polar functional groups that strongly anchor to the carbon black particle surface through multiple forces such as covalent bonds, hydrogen bonds, and ionic interactions.

Y-end: Contains active groups such as polysulfide bonds and double bonds, which undergo chemical reactions with the terminal aldehyde groups or the main chains of Natural Rubber (NR) molecules during vulcanization, achieving co-crosslinking.

3. Fundamental Changes Achieved

Reduce free ends: Seal the ends of rubber molecular chains, reducing friction and heat generation.

Improve dispersion: Achieve uniform dispersion of carbon black particles, reducing local stress concentration.

Stabilize the crosslink network: Prevent the breakage of polysulfide bonds under thermo-oxidative conditions (i.e., “reversion”), enhancing network stability.

II. Performance Enhancement: Data-Driven Outstanding Performance

Laboratory and application test data fully demonstrate the comprehensive performance improvements brought by the AF Series products.

- Significantly Optimized Dynamic Performance (Suitable for Tires and Damping Products)

Reduce Rolling Resistance/Heat Build-up: The tan δ @60°C value decreased by over 18% (from 0.098 to 0.08), meaning a significant reduction in tire rolling resistance and potential improvement in electric vehicle range.

Enhance Anti-Fatigue Performance: Reduced compression heat build-up and significantly extended dynamic fatigue life.

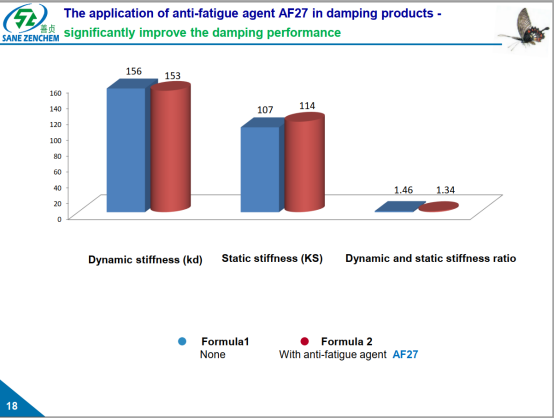

Improve Dynamic Properties of Rubber: The dynamic-to-static stiffness ratio (Kd/Ks) decreased from 1.46 to 1.34, indicating better comfort for damping products.

2. Enhanced Physical-Mechanical Properties and Durability

Prevent Rubber Reversion: After high-temperature prolonged vulcanization, the AF28 formulation maintained higher modulus and crosslink density stability.

Improve Heat Aging Resistance: Higher retention of tensile strength and elongation at break after aging, leading to longer product life.

Maintain Comprehensive Properties: While significantly reducing heat generation, key indicators such as tensile strength and tear strength remain stable or even slightly improved.

Table: Key Performance Data Comparison of AF28 in Tire Compound

| Test Item | Standard Formula | Standard Formula + AF28 | Trend | Test Standard |

| tan δ @60°C | 0.098 | 0.080 | ↓18.4% | ISO-23337 |

| Rebound Resilience (%) | 43 | 49 | ↑14.0% | GB/T 1681 |

| Rolling Resistance Improvement Rate | Baseline (100%) | 81.6% | ||

| T90 Curing Time (min) | 10.21 | 7.21 | ↓29.4% | GB/T 16584 |

| Tensile Strength after Aging | 25.4 MPa | 26.9 MPa | ↑5.9% | ASTM D412 |

III. Environmental and Economic Benefits: Not Bio-based, But a True Low-Carbon Enabler

The environmental value of the AF Series comes not from bio-based raw materials but is achieved through its outstanding “carbon reduction” application effects.

Energy Saving and Consumption Reduction: As an efficient tire additive, it effectively reduces rolling resistance, saving approximately 3-5% fuel/electricity per vehicle. This is the largest carbon emission reduction contribution during the product lifecycle.

Extended Service Life: Used in engineering rubber products (e.g., shock absorbers, seals), its anti fatigue and anti reversion properties can significantly extend product replacement cycles, reducing resource consumption and waste generation.

Improved Production Efficiency: Shortened curing time (T90 reduced by up to ~30%) means lower energy consumption, increased production efficiency, and indirectly reduced carbon emissions.

IV. Application Guide: Keys to Maximizing Product Efficacy

Strict process requirements are crucial to ensure the AF Series anti-fatigue agents for natural rubber achieve maximum effectiveness.

Applicable Systems: Compounds based on Natural Rubber (NR) or NR/BR blends. Effectiveness is limited in systems dominated by synthetic rubber.

Recommended Dosage: 1.0 – 1.6 phr. Can be fine-tuned based on specific performance requirements and cost considerations.

Processing Key: Must be added simultaneously with NR, carbon black, and other raw materials during the first mixing stage (non-productive phase). This ensures sufficient time and shear force for complete dispersion and pre-reaction. Optimal dispersion is achieved in an internal mixer at 110-130°C alongside carbon black.

Conclusion: Partner with SaneZen to Co-create a Green Future

The AF Series anti fatigue agents represent a paradigm shift in the field of rubber chemicals—from physical mixing to chemical customization, from improving processing to enabling performance. It is not only a key to upgrading product grades but also a strategic material for rubber manufacturers responding to the EU Green Deal and meeting downstream customers’ low-carbon demands.

As a leading Special Rubber chemical Manufacturer, Supplier, and Factory, SaneZen provides the optimal solution for tire rolling resistance and rubber reversion prevention. Our expertise helps customers address how to reduce rubber heat buildup and improve the dynamic properties of rubber.

Take action now to get your products ahead of the curve:

Welcome to contact our professional technical team for customized application solutions, free samples, and in-depth technical support.

SaneZen Group – We are professional and dedicated to the future of the rubber industry

*Website: www.sanezenrubber.com

Email yorichen@sanezen.com