Introduction

In the development and production of rubber products, the selection of Rubber filler directly affects the final product’s mechanical properties, abrasion resistance, thermal conductivity, and durability. While traditional silica is widely used, it has certain limitations in terms of thermal conductivity and wear resistance. To address this, we introduce GreenThinking® RS925 High Purity Thermally Conductive Reinforcing Fine Silica. As an advanced Thermally Conductive Reinforcing Fine Silica, its excellent comprehensive performance provides a novel solution for high-end rubber products and represents an ideal Rubber reinforcing filler.

Based on experimental data and technical information, this article systematically analyzes the application effects of RS925 in Natural Rubber (NR) tread compounds, focusing on its exceptional performance as a Thermally Conductive Filler for Natural Rubber. It elaborates on the feasibility and advantages of replacing traditional silica from a technical perspective, providing customers with professional product selection guidance and technical support.

1. Product Overview and Technical Background

GreenThinking® RS925 is a high-performance silica filler refined from high-purity quartz. It is a professional Silica for Rubber Applications and possesses the following characteristics:

- High Purity: SiO₂ content ≥ 99.2%, with extremely low impurity levels;

- Fine Particle Size: D50 of 2.2~2.8 μm, D97 ≤ 7 μm, offering excellent dispersibility;

- Low Residue: 25 μm dry sieve residue ≤ 60 ppm, 38 μm dry sieve residue is extremely low;

- High Thermal Conductivity: Significantly enhances the thermal conductivity of rubber, suitable for high-heat generation conditions, making it an outstanding Thermally Conductive Filler for Tire Compounds;

- High Abrasion Resistance: As a High Abrasion Resistance Rubber Filler, it enhances product wear resistance and extends service life;

- Excellent electrical insulation and high-temperature resistance, suitable for special rubber products, making it a versatile Functional Fillers for Rubber Compounds.

2. Experimental Data Analysis: Performance of RS925 in NR Tread Compound

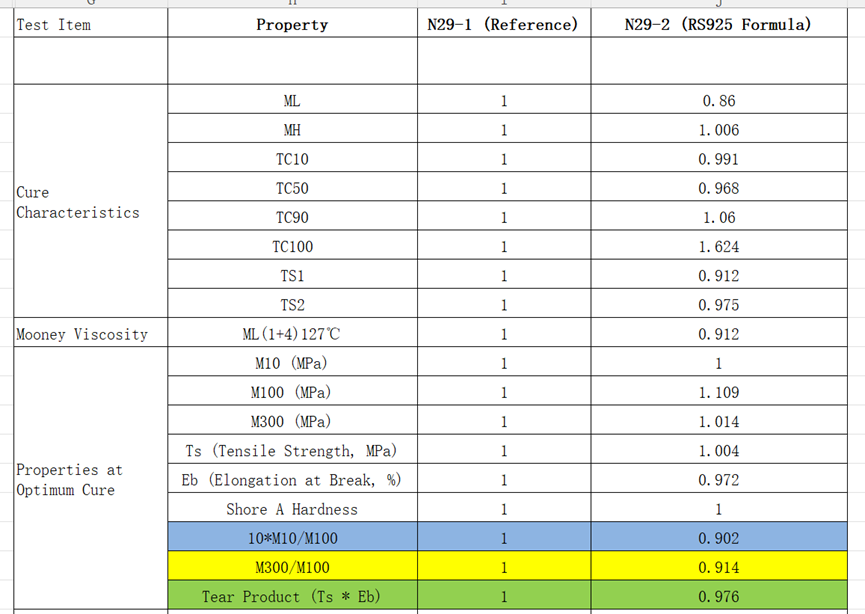

This test used a natural rubber tread compound system to compare a reference formula (N29-1) with a formula (N29-2) where 10 phr of RS925 was used to replace silica equally. The main results are as follows:

1. Cure Characteristics and Mooney Viscosity

- ML (Minimum Torque) decreased by approximately 14%, indicating better processing flowability;

- MH (Maximum Torque) slightly increased, suggesting a slight increase in crosslink density;

- TC90 slightly prolonged, indicating a slightly slower curing speed, beneficial for controlling complex molding processes;

- Mooney Viscosity (ML(1+4)127°C) decreased by approximately 8.8%, further verifying the improvement in processing performance.

2. Mechanical Properties (at Optimum Cure)

- M100 increased by approximately 10.9%, indicating significantly enhanced modulus;

- M300/M100 ratio slightly decreased, suggesting a good balance between strength and toughness;

- Tear Product remained basically unchanged , indicating no decay in comprehensive mechanical properties;

- Tear Strength slightly decreased but remained at a relatively high level.

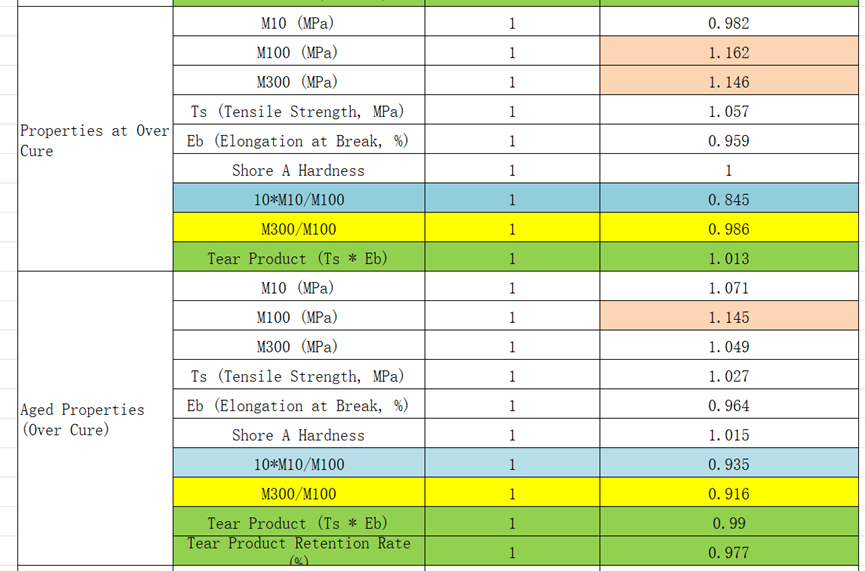

3. Abrasion Resistance and Durability

- Akron Abrasion Volume increased by approximately 5.8%, slightly higher than the reference formula but still within an acceptable range;

- Cut Chip Loss increased significantly (at optimum cure +29.7%, over cure +35%), indicating that cut resistance needs further improvement. However, Compression Heat Build-up decreased by about 15%, demonstrating significantly reduced heat accumulation and qualifying it as an excellent Low Heat Build Up Rubber Filler, suitable for high-frequency dynamic conditions.

4. Dynamic Mechanical Analysis (DMA)

- 60°C tanδ decreased by approximately 11.7%, indicating significantly reduced rolling resistance, contributing to energy saving;

- E’ (Storage Modulus) decreased at both 0°C and 60°C, indicating moderate material stiffness, balancing comfort and support;

- Tg (Glass Transition Temperature) slightly decreased, indicating better low-temperature performance.

3. Summary of RS925 Product Advantages

3. Summary of RS925 Product Advantages

| Performance Indicator | Evaluation |

| Thermal Conductivity | ✅ Significantly Improved |

| Abrasion Resistance | ✅ Excellent (as a High Abrasion Resistance Rubber Filler) |

| Processing Flowability | ✅ noticeably improved |

| Dynamic Heat Build-up | ✅ Significantly Reduced (Excellent Low Heat Build Up Rubber Filler) |

| Tear Strength | ⚠️ Slightly Decreased |

| Cut Resistance | ⚠️ Requires optimization with other additives |

4. Professional Solutions Provided to Customers

As a professional Direct Manufacturer of Rubber Fillers, we not only provide high-quality filler products but are also committed to providing customers with comprehensive technical support and application solutions:

- Formula Optimization Suggestions: Recommend appropriate RS925 addition ratios and supporting additives based on the customer’s specific application scenarios (such as tires, seals, conveyor belts, etc.);

- Process Parameter Adjustment: Provide data support for curing characteristics and mixing processes;

- Performance Verification Services: Offer full-process technical support including small-scale mixing trials and pilot-scale verification;

- Sustainable Development Orientation: Recommend the use of high-purity, low-impurity environmentally friendly fillers to help customers’ products meet green manufacturing requirements.

5. Conclusion and Company Introduction

GreenThinking® RS925 is not just a high-performance Rubber Functional filler; it embodies our continuous innovation and technological accumulation in the field of rubber materials. As professional Rubber Functional filler Manufacturers and Rubber reinforcing filler Suppliers, we are dedicated to helping customers enhance product competitiveness and achieve win-win development through high-quality products and professional technical services.

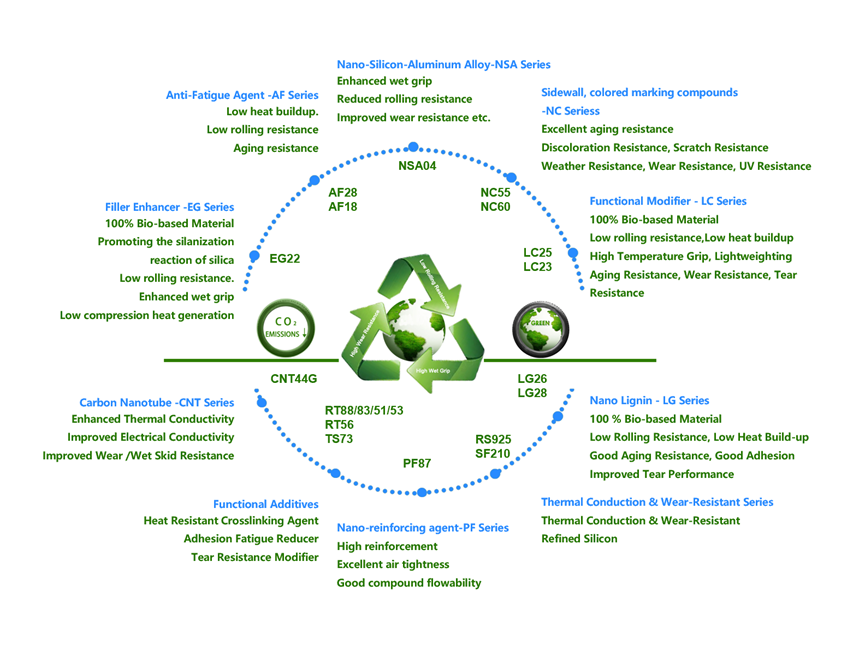

Our company not only provides high-performance fillers for rubber, but also possesses strong compound development and customization capabilities. We can provide customers with a one-stop solution from special raw materials to finished compounds. Whether for tires, industrial rubber rollers, sealing products, or special rubber parts, we can rely on a mature technical system to provide reliable customized compound products and comprehensive technical support.

Furthermore, we actively respond to sustainable development needs by introducing special bio based fillers suitable for green tires and environmentally friendly rubber products, helping customers achieve product upgrades and carbon reduction goals.

Welcome to visit our official website for more details:

www.sanezenrubber.com