The “explosion-type sidewall bubble” in all-steel radial truck tires has been a major quality issue plaguing the industry for years, making finding effective Sidewall Bubble Solutions an urgent task. This article systematically analyzes the causes of this defect, identifying residual gas and high moisture content in the green tire as the core factors, and proposes a systematic Solution for tire Bubble Problem combining “process optimization” and “material upgrade.” This is crucial for achieving Steel Truck Tire Quality Improvement. It elaborates on how the specifically developed High Performance Sidewall Compound – ColorRubber NC55 sidewall compound by Anhui Shengxin rubber mixing plant – effectively suppresses bubble formation at the source through its characteristics such as low moisture, high air tightness, and excellent processability. As professional Custom Rubber compound Suppliers and Custom Rubber compound Manufacturers, we, along with local experts like Custom Rubber compound Manufacturers China and Custom Rubber compound Suppliers China, are committed to providing reliable material choices for tire enterprises to enhance product qualification rates and strengthen market competitiveness.

1. Introduction

The manufacturing process of all-steel radial truck tires is complex and requires extreme precision. Among numerous finished tire defects, the “explosion-type sidewall bubble” has become a key concern within the industry due to its concealment and severity. This defect not only leads to tire scrap, causing significant economic losses, but also poses potential safety risks. Traditional solutions have mostly focused on adjusting process parameters like shaping and curing. However, practice has proven that relying solely on process optimization often addresses the symptoms, not the root cause. This is the fundamental reason why many enterprises seek How to Solve Steel Belted Tire Sidewall Blistering. Based on over twenty years of rubber R&D experience, Anhui Shengxin mixing plant proposes a breakthrough starting from the material source. By applying high-performance sidewall compounds and combining them with process improvements, this challenge can be systematically overcome, offering a new perspective on Tire Sidewall Bulge Causes and Treatment.

2. Characteristics and Root Cause Analysis of Explosion-Type Sidewall Bubbles

2.1 Defect Characteristics

Explosion-type bubbles mostly occur in the tire horizontal axis area. Their typical characteristics are:

- Appearance: The sidewall compound bulges in an explosive manner or tears, exposing the steel carcass cords in severe cases. This is a typical Sidewall Bubble Defect in Tire Manufacturing.

- Internal: X-ray inspection reveals that the bubbles compress the carcass cords, causing them to become sparse and disordered.

- Location Concentration: Defect points are mostly concentrated in the carcass splice area, where the cord surface often exhibits an abnormal blue sheen.

2.2 Root Cause Analysis

Comprehensive analysis indicates that the formation of explosion-type bubbles results from the coupling of multiple factors. The core roots can be summarized as two points:

- Residual Gas in the Green Tire: During the tire building process, semi-components like carcass ply, inner liner, and sidewall compound are layered together. If the lamination is not tight or rolling/venting is insufficient, gas becomes trapped. In the subsequent curing process, the sidewall area, due to its large curvature and being the last to contact the mold, allows the internal gas to migrate and accumulate towards the less constrained sidewall when heated and expanded, finally forming visible bubbles. Therefore, mastering How to Eliminate Bubbles During Tire Curing is key to process control.

- Excessive Moisture Content in the Green Tire: Moisture attached to the compound or steel cords rapidly vaporizes under the high temperature of curing, generating enormous pressure. Simultaneously, water acts as a medium, accelerating the chemical reaction between the copper coating on the cord surface and sulfides in the rubber, generating blue compounds like copper sulfide and copper oxide, which destroy the adhesion interface between the cord and the rubber, providing a channel for bubble formation and expansion.

3. Systematic Solution: A Dual-Driven Approach by Process and Material

To effectively control sidewall bubbles, a systematic defense line covering process management and material selection must be established.

3.1 Process Optimization Control Measures

This section covers common industry improvement methods aimed at providing a synergistic effect for material upgrades:

- Strictly Control Moisture Content of Semi-Components: Ensure adequate drying time and temperature, control humidity in the calendaring area, and ensure components are thoroughly air-dried after cooling.

- Optimize Carcass Splice Quality: Use carcass stitchers to ensure smooth splices, reducing air pockets caused by uneven joints.

- Refined Rolling and Venting: Adopt segmented rolling devices to apply differentiated pressure and frequency to different areas, ensuring thorough interlayer air removal.

- Bladder Turn-Up System Upgrade: For example, by shortening the bladder length or adding anti-slip mesh, enhance the sidewall turn-up compaction to prevent edge air entrapment.

3.2 Material Upgrade Solution – The Key Role of High-Performance Sidewall Compound

Process control solves the problem of “how to make the product correctly,” while material upgrade addresses the fundamental issue of “what kind of material can make it better and more stable.” This involves Sourcing High Quality Compound for Tire Production and choosing a Reliable Rubber Compound Supplier for Tires. Targeting the causes of sidewall bubbles, the Anhui Shengxin ColorRubber NC55 sidewall compound is genetically designed from its formula inception to tackle this challenge. It is an excellent example to guide you on How to Choose Anti-aging Sidewall Rubber Compound.

Correlation Between NC55 Product Characteristics and Bubble Suppression Capability:

- Targeting “High Moisture Content”: NC55 implements strict low-humidity environment control and drying processes from raw material selection through the entire production process, ensuring the出厂 product itself has extremely low moisture content, fundamentally reducing the source of steam generated during curing.

- Targeting “Residual Gas”:

- Excellent Processing Fluidity: Its Mooney viscosity is stable around 39.6 (ML 1+4 @125°C), with a scorch time as long as 19.42 minutes. This means the compound has better spreadability and fillability during building, more effectively expelling interlayer air while maintaining sufficient operational safety.

- Balanced Curing Characteristics: A reasonable TC90 time ensures the compound can fully flow and complete degassing in the mold cavity before rapidly setting, avoiding gas entrapment due to overly fast curing.

- Enhanced Interface Adhesion and Durability:

- High Rubber Content and Strong Strength System: Provides excellent tensile strength (≥13.58 MPa) and elongation at break (≥721%). The powerful cohesion makes its adhesion to the carcass ply stronger, less prone to interfacial separation due to gas or steam pressure.

- Exceptional Aging Resistance: A unique anti-UV and ozone resistance system effectively prevents the sidewall from developing micro-cracks due to sunlight aging during use, blocking channels for later moisture and oxygen ingress, providing long-term quality assurance, ultimately helping tire manufacturers Improve Tire Durability and Service Life.

4. Anhui Shengxin: A Reliable Partner Backed by R&D StrengthChoosing a material means choosing the technical support and supply chain guarantee behind it. Anhui Shengxin mixing plant is such a trustworthy partner.

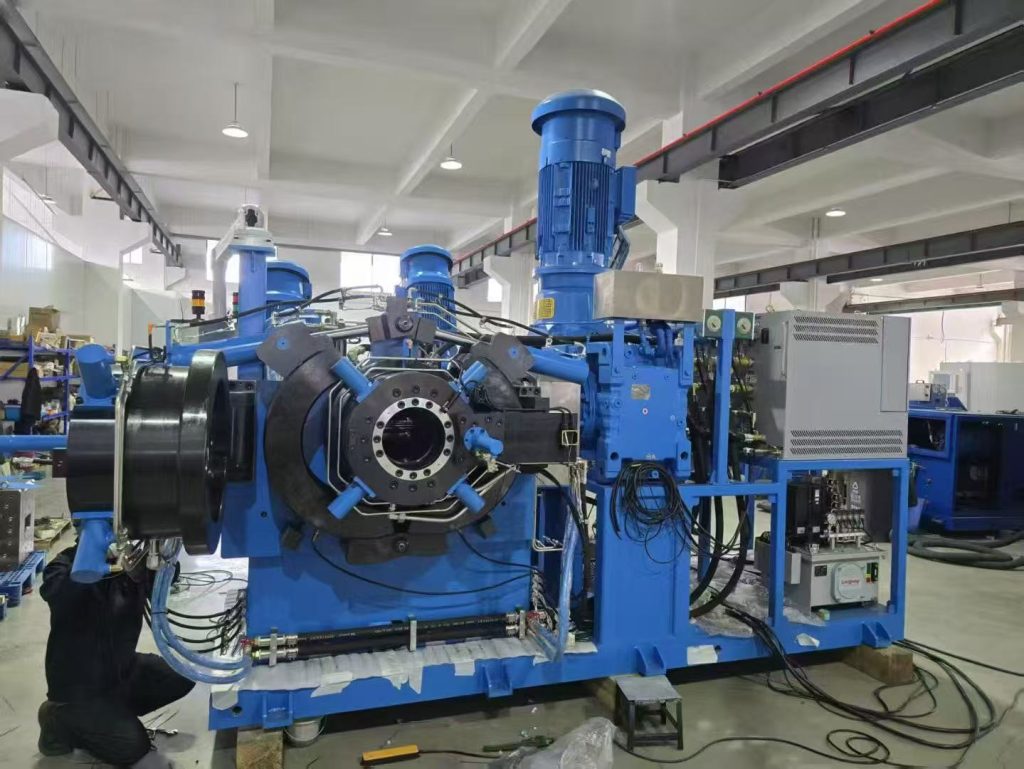

- Scale and Specialized Production Capacity: We have an annual production capacity of 150,000+ tons of mixed compound and operate 26 professional rubber compound production lines, including independent color compound lines, ensuring product consistency and stability.

- Profound R&D Heritage: With over 20 years of deep industry experience, we have accumulated a database of 10,000+ mature rubber formulas. This enables us not only to provide standard products like NC55 with outstanding performance but also to offer efficient custom formula development services according to customers’ specific equipment, processes, and performance requirements, truly achieving “tailor-made” solutions.

5. Conclusion

The explosion-type sidewall bubble issue in all-steel radial truck tires is a typical systemic problem. It can be effectively prevented and controlled through the dual approach of “Refined Process Control” and “High-Performance Material Application”. The ColorRubber NC55 sidewall compound launched by Anhui Shengxin mixing plant, with its low moisture, excellent processing fluidity, strong physical mechanical properties, and exceptional aging resistance, accurately targets the root causes of bubble formation, providing tire companies with an effective solution from the material end.

We firmly believe that through close cooperation with tire manufacturers, using Shengxin’s R&D strength and product performance as the leverage, we will jointly push the product quality of all-steel radial truck tires to new heights.