In power transmission, communication cables, marine engineering, and new energy sectors, increasingly stringent demands are placed on the conductivity, mechanical strength, aging resistance, and electromagnetic shielding effectiveness of cable materials. While traditional conductive carbon black can impart certain conductivity to rubber, its high loading levels often come at the cost of material flexibility, resilience, and processing performance. Balancing guaranteed electrical conductivity with comprehensive mechanical properties and processing technology has become a key challenge for technological upgrades in the cable industry.

SaneZen Group’s CNT44G Carbon Nanotubes, specifically developed as a high-performance Conductive Carbon Nanotube solution, with their unique nanostructure and excellent comprehensive properties, offer a novel conductive enhancement solution for the cable industry. This article systematically elaborates on the application performance and technical advantages of CNT44G in cable materials, based on the latest experimental data and technical information, focusing on its role for conductive rubber compounds.

I. Carbon Nanotube Technology Introduction: Why Choose CNT44G?

Carbon Nanotubes, specifically Multi walled Carbon Nanotube structures, are nano-scale tubular structures formed by carbon atoms via sp² hybridization, possessing the following core characteristics:

- Ultra-high Electrical Conductivity: Electrical conductivity approximately 10,000 times that of copper, enabling the construction of efficient conductive networks at very low loadings, making Carbon Nanotube ideal for cable shielding application.

- Exceptional Mechanical Properties: Tensile strength approximately 100 times that of steel, significantly enhancing material tensile and tear resistance.

- Excellent Thermal Conductivity: Effectively dissipates heat generated during cable operation, delaying aging.

- Nano-Reinforcement Effect: Forms strong interfacial bonds with the rubber matrix, disperses stress, and inhibits crack propagation.

CNT44G, a Multi walled Carbon Nanotube product specifically developed by SaneZen Group for rubber systems, retains the aforementioned properties while offering processing advantages such as ease of dispersion, good compatibility with rubber, and minimal impact on vulcanization characteristics, positioning it as a Cost effective Carbon Nanotube for wire and cable.

II. Performance of CNT44G in Cable Materials

1. Significantly Enhanced Conductivity, Achieving Low Resistance and High Shielding Effectiveness

According to a test report from collaboration between SaneZen Group and Dongfang Cable, adding 6 phr CNT44G + 30 phr conductive carbon black in an EPDM cable compound (a key application of Carbon Nanotube for EPDM cable) achieved a volume resistivity of 38 Ω·cm, while maintaining an elongation at break of 390%, demonstrating excellent conductivity and retention of elasticity.

Further tests indicate that increasing the CNT44G loading to 7 phr can reduce volume resistivity below 10 Ω·cm, fully meeting the high conductivity requirements for electromagnetic shielding layers, especially suitable for applications with stringent shielding performance demands such as Carbon Nanotube marine cable and high-voltage cables, effectively Improve cable shielding with Carbon Nanotube. This performance is also delivered through our specialized High conductivity CNT masterbatch.

2. Enhanced Mechanical Properties, Extending Cable Service Life

In EPDM compounds, the addition of CNT44G not only shows no significant impact on vulcanization characteristics but also markedly improves:

- Tensile Strength and Modulus (M100)

- Tear Strength

- Abrasion Resistance

These improvements make cables more resistant to mechanical damage during installation and operation, particularly outstanding in dynamic installation environments like submarine cables, underscoring the value of Carbon Nanotube for submarine cable insulation and reinforcement.

3. Excellent Aging Resistance, Low Compression Set

In hot air aging tests at 120°C × 70 hours, CNT44G-modified EPDM materials exhibit:

- Minimal Hardness Change

- High Retention of Tensile Strength

- Significantly Reduced Compression Set

This means cables can maintain good sealing performance and structural stability even under long-term high-temperature operating conditions, a critical factor for materials that Carbon nanotube for wire coating

III. Typical Application Scenarios for CNT44G in Cables

| Application Area | Performance Requirements | CNT44G Solution |

| Medium/Low Voltage Cables | Anti-static, Flexibility | 1–3 phr achieves anti-static (<10⁴ Ω) |

| High Voltage Shielded Cables | High Conductivity, EMI Shielding (a key function of Submarine cable EMI shielding material) | 5–7 phr achieves volume resistivity <10 Ω·cm |

| Submarine & Special Cables (e.g., Carbon Nanotube marine cable) | Water Resistance, Corrosion Resistance, Fatigue Resistance | Enhances mechanical strength, improves shielding effectiveness |

| Flexible Cables & Robot Cables | High Resilience, Flex Endurance | Maintains elasticity at low loadings, extends service life |

IV. SaneZen Group: Rooted in Rubber Material Technology, Driving Industry Innovation and Sustainable Development

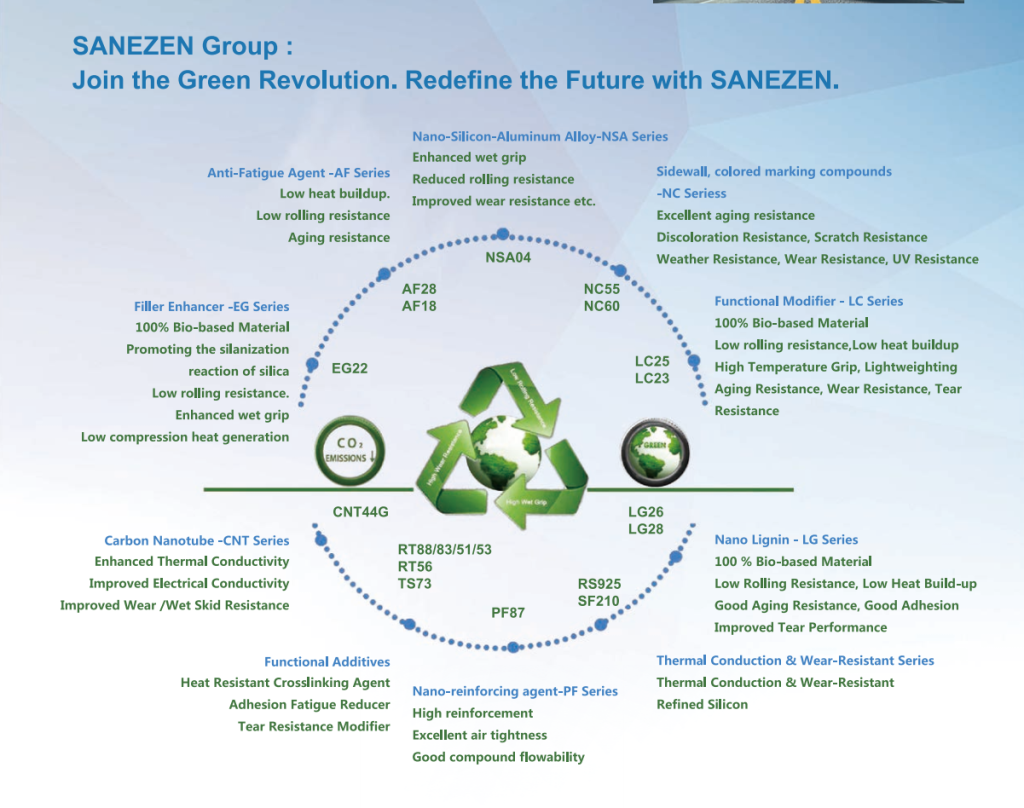

SaneZen Group is a global developer and producer of high-end rubber materials, driven by the mission of “Technology Powering a Sustainable Future.” We understand that high-performance rubber is indispensable across numerous industrial fields, from high-speed tires – where we are also recognized among leading Carbon Nanotube tyre industry Suppliers China and global Carbon Nanotube tyre industry Manufacturers – to cables ensuring energy transmission. To this end, we have established three technical centers in Shanghai, Anhui, and Changzhou, building a comprehensive R&D network covering basic research, application development, and industrial transformation.

In the specific field of cable materials, we do not simply provide a single product. Instead, based on a deep understanding of polymer structure and properties, we offer customers integrated material solutions. CNT44G Carbon Nanotubes is one of the star products born from this philosophy. Beyond this, we possess a complete portfolio of high-performance, functional, and eco-friendly products to help cable manufacturers meet increasingly stringent performance and environmental challenges, solidifying our role as a key Carbon Nanotube tyre industry Supplier for advanced materials.

Core Product Series Tailored for the Cable Industry:

- CNT Series Carbon Nanotubes: Not only efficient Conductive Carbon Nanotube but also exceptional nano-reinforcements, comprehensively enhancing cable conductivity, thermal conductivity, abrasion resistance, and mechanical strength, perfect for conductive rubber compounds.

- PF Series Nano-Reinforcing Agent: Provides lightweight reinforcement, enhances modulus and tear resistance while maintaining compound flexibility, suitable for cable sheathing requiring low weight and flexibility.

- RT/TS Thermal Conduction & Wear-Resistant Series: Specifically designed to improve the thermal conductivity of compounds, helping to rapidly dissipate internal heat generated during cable operation, while imparting excellent surface wear resistance, extending service life in outdoor and mobile scenarios.

- RS Series Adhesion Promoters: Ensure strong adhesion between rubber and metal shielding layers, fiber reinforcement layers, or different rubber components, safeguarding the integrity and reliability of cable structure.

- EG Series Fully Bio-based Filler Enhancer & LG Series Nano-Lignin: Offer bio-based solutions for customers pursuing green environmental protection and reduced carbon footprint, demonstrating excellent performance in improving processability, reducing rolling resistance (particularly important for moving cable reels), and enhancing aging resistance.

AF Series Anti-Fatigue Agents: Effectively reduce heat generation in compounds under dynamic use, preventing premature failure due to thermal aging, especially suitable for frequently flexing cables like robot cables and port machinery cables.

Driven by the dual engines of “Material Innovation + Process Excellence” and guided by our proprietary Dynamic Reinforcement Model for optimizing filler network structures, we achieve breakthroughs not only in performance but also help customers reduce energy consumption during mixing, minimize heat buildup, and enhance production efficiency. We are committed to advancing the cable industry towards higher performance, lower energy consumption, and greater sustainability.

Conclusion

CNT44G Carbon Nanotubes have demonstrated significant application potential in the cable industry, owing to their comprehensive advantages in conductivity, mechanical enhancement, and processing friendliness, making them a superior choice for cable shielding application and other demanding uses. SaneZen Group is ready to collaborate with cable manufacturers, leveraging solid experimental data and mature rubber material expertise to provide full-process technical solutions from material selection and compound formulation optimization to process support, offering a Cost effective Carbon Nanotube for wire and cable.

SaneZen Group – We are deeply rooted in rubber material technology. We are not only your reliable supplier but also your trusted technical partner.