Introduction

Carbon nanotubes (CNTs) have attracted significant interest in material science due to their exceptional electrical, thermal, and mechanical properties. As a high-performance rubber functional filler, multi-walled carbon nanotubes like CNT44G offer a compelling balance of performance and processability. This technical document summarizes the benefits of integrating CNT44G into fluorocarbon (FKM compound) and ethylene-propylene-diene (EPDM compound) rubber formulations, supported by experimental data and aligned with contemporary research trends.

CNT44G Overview

CNT44G is a highly structured multi-walled carbon nanotube specifically engineered for elastomer reinforcement and conductivity enhancement. Sourced from leading carbon nanotube manufacturers and carbon nanotube suppliers, this advanced functional filler enables the formation of conductive networks at low loading levels, making it ideal for applications requiring antistatic protection, EMI shielding, and improved mechanical performance in various rubber compound systems.

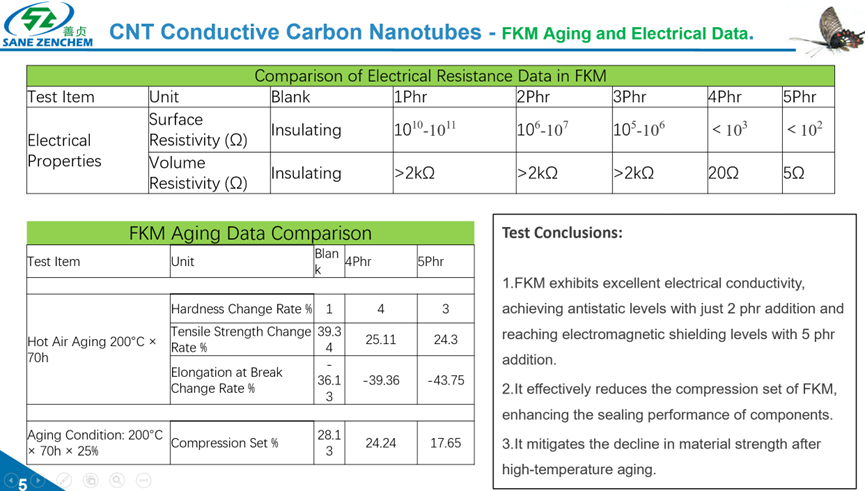

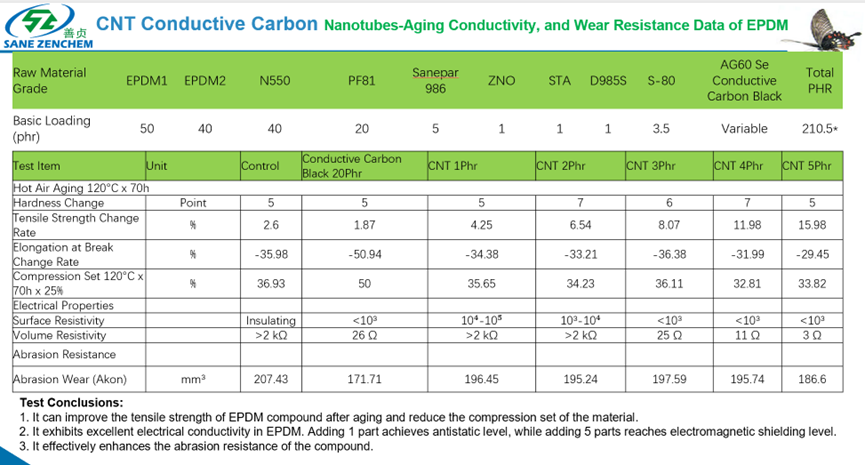

- Efficient Conductive Network Formation

CNT44G facilitates percolation at very low loadings. In FKM compound, surface resistivity falls below 10³ Ω with only 4 phr, reaching electromagnetic shielding levels (<10² Ω) at 5 phr. Similarly, in EPDM compound, antistatic performance (10⁴–10⁵ Ω) is achieved with just 1 phr, and EMI shielding is possible with 3–5 phr. - Enhanced Mechanical Properties

The nanotube structure contributes to notable improvements in modulus, tensile strength, and tear resistance. In FKM compound, tear strength increased from 27.16 kN/m (control) to 40.52 kN/m with 5 phr CNT44G. EPDM compound also exhibited improved tear strength and modulus with low loadings (1–5 phr), outperforming conventional carbon black-filled compounds. - Aging and Compression Set Resistance

CNT44G helps maintain mechanical integrity under thermal aging. In FKM compound aged at 200°C for 70 hours, the compression set was reduced from 28.13% (control) to 17.65% with 5 phr CNT44G. EPDM compound also showed improved aging resistance and lower compression set values compared to conductive carbon black references. - Processing Benefits

Unlike conductive carbon black, which requires high loadings (e.g., 20 phr in EPDM compound) to achieve conductivity, CNT44G enables equivalent or superior performance at ≤5 phr, resulting in lower compound viscosity, easier processing, and better retention of elastomeric properties.

Experimental Data Summary

- FKM compound:

Vulcanization acceleration observed (reduced TC90).

Mechanical properties enhanced even after thermal aging.

Excellent conductivity achieved with 4–5 phr. - EPDM compound:

Minimal impact on curing characteristics.

Mechanical reinforcement and conductivity at 1–5 phr loadings.

Superior abrasion resistance and aging performance compared to carbon black.

Alignment with Current Research

Recent studies emphasize the importance of CNT dispersion and network stability in polymer matrices (e.g., Composites Science and Technology, 2023). Sourced from professional rubber functional filler manufacturers and rubber functional filler suppliers, CNT44G’s surface compatibility with polar and non-polar rubbers aligns with these findings, supporting its effectiveness in both FKM compound and EPDM compound without requiring extensive chemical modification.

Applications

CNT44G is particularly suited for:

- Static-dissipative and conductive seals/gaskets (automotive, aerospace)

- Conductive hoses and tubing

- EMI shielding components

- Industrial rolls and conveyor belts

- Explosion-proof and antistatic rubber products

Manufacturing Strength and Support

Backed by our manufacturing base at Anhui Lixin Rubber Technology Co., Ltd.—one of China’s top five rubber mixing factories with an annual output of over 150,000 metric tons—we ensure material quality, batch consistency, and comprehensive technical support across a full range of rubber types. As experienced FKM compound manufacturers and EPDM compound manufacturers, our core competencies include coverage of 33+ rubber types, more than 20 years of professional R&D and production experience, a dedicated independent colored rubber compounding facility, 26+ professional compound production lines including specialty rubber-dedicated lines, and a portfolio of 10,000+ validated rubber compound recipes. Should you require compounds such as FKM, EPDM, or full-range formula design incorporating materials like CNT44G—available through trusted carbon nanotube suppliers and rubber functional filler suppliers—we welcome sample requests and technical collaboration.

Conclusion

CNT44G offers a technically advanced and economically efficient functional filler for enhancing the electrical and mechanical properties of FKM compound and EPDM compound. Its ability to provide stable conductivity, improve mechanical performance, and support processing efficiency makes it a suitable choice for high-value rubber applications in demanding environments.