In the arena of materials science, flame retardancy and environmental protection were once considered irreconcilable contradictions. Traditional halogenated flame retardants dominated the market for decades due to their high efficiency, but they also buried hidden concerns for the environment and safety—the dense smoke and toxic hydrogen halide gases released during combustion became “invisible killers” in fires. The increasing stringency of global environmental regulations, particularly the EU’s RoHS, REACH, WEEE directives, and China’s mandatory standards for rail transit materials, has completely changed the rules of the game. A profound transformation toward halogen-free, low-smoke, and high-efficiency flame retardant technology is now underway, driving demand for a true high performance halogen free flame retardant.

It is at this historic turning point that Anhui Sanexin Polymer Fine Material Co., Ltd., a leading flame retardant manufacturer in China and a key player among halogen free environmentally friendly flame retardant Manufacturers, leveraging its forward-looking technological layout and deep R&D expertise, has introduced the epoch-making GreenThinking® FR99RP High-Efficiency Composite Halogen Free Flame Retardant. As a premier halogen free flame retardant Suppliers, it is not merely a product but a future-oriented flame retardant solution designed to address the industry’s long-standing core pain point: How can we achieve the perfect unity of flame retardant efficacy, physical/mechanical properties, and processing performance while completely eliminating halogens? This question is central to how to choose UL94 V0 grade halogen-free flame retardant.

Part 1: Confronting the Three Major Industry Pain Points—FR99RP’s Breakthrough Solutions

Pain Point 1: The “Cliff” Between Environmental Compliance and High Performance

With global restrictions on Persistent Organic Pollutants (POPs), brominated flame retardants such as Polybrominated Biphenyls (PBBs) and Polybrominated Diphenyl Ethers (PBDEs) have been explicitly banned or strictly limited. When the market shifted to halogen-free alternatives, it generally encountered a performance “cliff”: ordinary halogen-free flame retardants (e.g., Aluminum Hydroxide, Magnesium Hydroxide) require extremely high loading levels (often exceeding 150 phr) to achieve a V-0 rating. This leads to a dramatic increase in material density, severe degradation of mechanical properties (especially tensile strength and elasticity), and worsened processing flow. This approach, which sacrifices core functional performance for environmental compliance, has left many manufacturers in a dilemma when seeking a RoHS REACH compliant flame retardant that doesn’t compromise on performance.

FR99RP’s Solution: Composite Synergy and Structural Design

The core innovation of FR99RP lies in its unique technological path of “super-refinement, activation, functionalization, and compounding.” It is not a single compound but a precisely designed high efficiency composite flame retardant system that achieves synergistic effects among multiple flame-retardant elements at the nanoscale. Its platelet structure undergoes special surface treatment, forming a stronger interfacial bond with the rubber/plastic matrix rather than simply acting as a physical filler, making it an exceptional rubber and plastic flame retardant additive.

Supporting Test Data:

In a comparative test using a 70 Shore A EPDM base formulation with a loading of 100 phr, positioning FR99RP as a premier EPDM rubber flame retardant and a high elasticity halogen free flame retardant for EPDM rubber:

- FR99RP vulcanizate achieved a tensile strength of 9.32 MPa, significantly higher than FR98RP’s 6.35 MPa.

- Elongation at break reached 497%, demonstrating excellent elasticity.

- Hardness was 76 Shore A, maintained within a reasonable range.

- Density was only 1.242 g/cm³, outstanding among products with the same flame retardant rating.

This means that with a moderate loading of 80-100 phr, the highest UL94 V0 halogen free flame retardant rating can be achieved while minimizing the increase in density and the “dilution effect” on the matrix’s mechanical properties. This breakthrough in performance balance solves a long-standing technical challenge in the industry.

Pain Point 2: The “Secondary Disaster” in Fire Safety—Smoke and Toxicity

In severe fire scenarios, especially in enclosed or densely populated spaces like subways, high-speed trains, and ships, the flame retardancy of materials is only the first line of defense. More deadly are the high concentrations of smoke and toxic gases produced during combustion, which severely hinder evacuation and fire rescue efforts. Traditional flame retardant systems often perform poorly in this regard, creating a need for a reliable low smoke halogen free flame retardant.

FR99RP’s Solution: Condensed-Phase Ceramification Flame Retardant Mechanism

FR99RP’s flame retardant action primarily occurs in the condensed phase. When exposed to high-temperature flames, it rapidly decomposes and expands on the material surface, forming a dense, strong, and porous ceramified char layer. This char layer acts like a dynamic “thermal shield,” providing three key functions:

- Thermal Barrier: Effectively blocks heat transfer to the substrate interior.

- Sealing Barrier: Prevents the escape of internal combustible gases and the ingress of external oxygen, cutting off the combustion chain.

- Carbon Fixation and Smoke Suppression: Fixes carbon elements within the solid char layer, significantly reducing the generation of soot particles.

Flame Retardant Performance Data:

- In a 70 Shore A EPDM formulation, 100 phr of FR99RP consistently achieves a UL94 V-0 rating.

- The Limiting Oxygen Index (LOI) is 35.4%, ensuring high-efficiency flame retardancy while avoiding the excessive expansion and soot issues associated with very high LOI values.

- Key Advantage: Compared to FR98RP (LOI 42.3%), FR99RP exhibits milder expansion during combustion and significantly reduced soot, more readily forming a complete ceramified protective layer.

Third-party tests indicate that products using FR99RP have smoke density ratings (SDR) and toxic gas emissions well below industry standard requirements, making them particularly suitable for applications with strict limits on smoke toxicity, such as rail transit and underground spaces, solidifying its role as a key rail transit flame retardant material.

Pain Point 3: The Balance Between Process Compatibility and Cost Control

The successful industrialization of a new material depends not only on its performance but also on its compatibility with existing production processes and overall cost. Many high-efficiency flame retardants are sensitive to processing temperatures, easily lead to scorching, or negatively affect the appearance of extruded products (surface roughness, ridges) due to poor dispersion, even exacerbating the wear and tear of the molds.

FR99RP’s Solution: Designed for Industrial Production

Excellent Processing Friendliness: The finely-sized particles (with a reasonable particle size distribution) treated with surface activators exhibit excellent dispersibility during mixing, avoiding localized performance weaknesses caused by agglomeration. The compound shows good fluidity and stable Mooney viscosity, enabling the production of high-quality products with precise dimensions and smooth surfaces in complex rubber extrusion and molding processes.

Optimized Curing Characteristics: Compared to similar products, FR99RP causes less interference with the curing system. Rheometer test data shows:

- In 70 Shore A EPDM, the TC90 (optimal cure time) for FR99RP-100 is 112 seconds, significantly shorter than the 221 seconds for FR98RP-100.

- TS2 (scorch time) is 41 seconds, indicating good processing safety.

- It effectively shortens the optimal cure time, improving production efficiency by over 20%.

Comprehensive Performance Retention, including exceptional high temperature compression set resistant flame retardant properties:

- Heat air aging test (100°C×70h): FR99RP vulcanizate shows only a 3-point change in hardness, a -3.54% change in tensile strength, and an -18.31% change in elongation at break, all significantly better than the comparative product.

- Compression set (120°C×24h) is only 31.43%, superior to FR98RP’s 52.94%.

- Resilience reaches 47%, providing better dynamic sealing performance.

Long Shelf Life and Stability: The product possesses excellent chemical stability and a shelf life of up to 2 years, ensuring supply chain stability and smooth production planning for partners wondering where to buy FR99RP flame retardant samples.

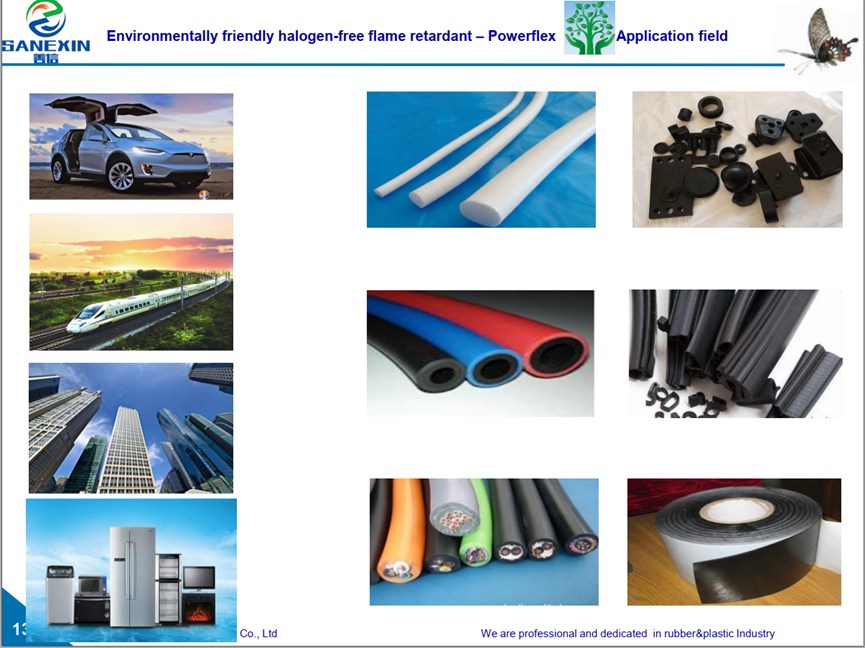

Part 2: Dominating High-End Application Fields—The Excellent Performance of FR99RP in Practice

The outstanding performance of FR99RP makes it an ideal choice to replace halogenated flame retardants in multiple high-end manufacturing sectors, offered by a customized rubber flame retardant solution provider.

1. The “Safety Armor” for Rail Transit

High-speed rail, subways, and intercity trains are evolving toward lighter weight, higher speed, and greater intelligence, imposing the highest level of fire safety requirements on all internal non-metallic materials. For example, components such as cable harnesses, seat elastomer parts, door/window sealing systems, and interior panels in EMUs must meet the most stringent Flame Retardant, Low Smoke, and Toxicity (FLST) standards.

Application Example: High-Speed Rail Carriage Sealing Strip. This component requires lifelong weather resistance, high elasticity, and flame retardant integrity under extreme fire conditions. EPDM compound using FR99RP not only meets standards like DIN5510-2/S2 SR2 (German rail vehicle fire protection standard) or the higher BS6853, making it a DIN5510 compliant flame retardant rubber material, but its excellent compression set resistance and resilience (tests show resilience over 47%) also ensure the sealing performance does not degrade over the vehicle’s entire lifecycle, avoiding increased energy consumption and noise due to seal aging. The solid ceramic layer formed after combustion effectively maintains the structural integrity of the seal, delaying the spread of flame and smoke between carriages. This makes it the perfect environmentally friendly flame retardant for high speed train carriage sealing strips.

2. The “Cell Guardian” for New Energy Vehicles

The power battery pack of a new energy vehicle is a high-energy-density enclosed system where safety is paramount. Rubber and plastic parts within the battery pack, such as insulating gaskets, high-voltage cable sheaths, connector seals, and battery module cushioning pads, have extremely demanding requirements for flame retardancy and thermal stability, defining the need for advanced new energy vehicle flame retardant solutions.

Application Example: Battery Module Fireproof Insulation Sheet. This type of material needs to maintain insulation and structural integrity for an extended period even when facing ejecta from a thermal runaway cell at temperatures exceeding 1000°C, buying critical time for occupant evacuation. FR99RP imparts excellent char-forming ability and thermal insulation properties to silicone rubber or high-performance elastomers. Its ceramified protective layer can effectively resist direct flame impingement and high-temperature heat flux, preventing fire from spreading to adjacent modules, meeting the mandatory V-0 flame retardancy requirements for battery systems set by global mainstream automakers. This represents a targeted flame retardant solution for new energy vehicle battery module insulation sheets.

3. The “Nerve Barrier” for High-End Cables

From server cables in data centers to high-voltage cables for new energy charging piles, to building intelligent cabling, modern cables demand both transmission efficiency and absolute safety. Halogen-Free Low Smoke Zero Halogen (LSZH) has become the global standard for high-end cables, creating a strong market for halogen free flame retardant for cables.

Application Advantage: FR99RP performs excellently in polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and various cable jacket rubbers. It enables cables to pass rigorous tests like IEC60332-3 (bunch burning) while ensuring the flexibility of the sheath material, the smoothness of the extruded surface, and the stable dielectric properties required for high-frequency signal transmission scenarios. As a trusted low smoke halogen free cable compound flame retardant supplier, SaneZen ensures consistent quality and performance.

4. The “Precision Protection” for Smart Electronics & Electricals

Components inside 5G base station equipment, server power supplies, and high-end home appliances—such as connectors, thermal pads, and internal cable clamps—have compact spaces, high heat dissipation requirements, and face dual challenges of demanding flame retardancy ratings (typically V-0) and long-term thermal stability (e.g., passing 85°C/85% RH double 85 tests).

Application Value: The addition of FR99RP has a minimal impact on the thermal conductivity of materials and can enhance the substrate’s heat aging resistance (high property retention after 100°C heat aging). This makes it is highly suitable for precise and durable application scenarios, helping electronic products to develop in the direction of being thinner, lighter and more reliable.

Part 3: SaneZen’s Strength: Full-Chain Assurance from Raw Materials to Certification

SaneZen is far from a simple material producer; we are a technology-driven solution provider and an EU certified environmentally friendly flame retardant manufacturer deeply engaged in the field of functional additives for rubber and plastics. Every performance promise for FR99RP is backed by a solid system:

Source-Level Raw Material Control: The core raw materials for FR99RP are carefully selected from global high-quality supplier and undergo 100% surface pre-treatment, forming the foundation for its excellent dispersibility. We have established strict raw material traceability and inspection standards.

Deep R&D and Process Know-How: The R&D center located in Shanghai continuously conducts research on flame retardant mechanisms and Optimization of the formula model. Our understanding of “compounding” is not simple mixing but involves molecular-level design and process regulation based on a profound understanding of polymer chemistry, rheology, and combustion science.

Comprehensive Quality and Certification System: Products undergo multiple online inspections during production and full-item analysis before final shipment. The FR99RP series has passed testing by authoritative third-party institutions, fully complying with EU RoHS 2.0, REACH (SVHC list), and WEEE directives. Our production base has the capability to provide customized products and dedicated technical support for high-end clients.

Extended Value of Technical Services: What we offer clients is more than just a Technical Data Sheet (TDS). We provide formulation optimization suggestions, processing parameter debugging support, and performance pre-evaluation simulating end-use applications based on extensive application data. We work with customers to tackle challenges and accelerate product time-to-market.

Conclusion: Choosing FR99RP Means Choosing a Certain Future

In the tide of green transformation in global manufacturing, material choices determine product competitiveness and corporate sustainable development capability. FR99RP represents a new possibility: Environmental protection, safety, and high performance require no compromise.

Verified through systematic experimental data:

- Flame Retardant Efficiency: A loading of 80-100 phr stably achieves a UL94 V-0 rating.

- Physical Properties: Tensile strength maintained above 9.32 MPa, elongation at break 497%, resilience 47%.

- Processing Performance: TC90 shortened to 112 seconds, improving production efficiency.

- Durability: Compression set only 31.43%, high property retention after heat aging.

- Environmental Certifications: Fully compliant with international environmental directives like RoHS, REACH, WEEE.

FR99RP, with objective data and practical application cases, answers technical experts’ doubts about reliability, addresses procurement managers’ concerns about cost and supply chain stability, and strengthens the confidence of business leaders in brand green competitiveness and long-term compliance risks.

From rigorous lab data to speeding high-speed trains, to smart appliances safeguarding millions of households, FR99RP is becoming a trusted benchmark in flame retardancy worldwide. SaneZen is willing to join hands with all partners to build a safer, greener era of manufacturing through the power of technology.

Take the First Step Toward Collaboration

We cordially invite you to request samples and detailed technical documentation for FR99RP, or to schedule a one-on-one application discussion with our technical engineers. Let’s jointly verify how this future-oriented halogen free environmentally friendly flame retardant can inject Outstanding safety genes and environmental protection value into your next-generation products.

Contact Us

Sane ZenChem (Shanghai) Co., Ltd.

Shanghai Tech & Business Center: Room 1606-1608, Boda Commercial Buildings, No. 11 Puhuitang Road, Xuhui District, Shanghai, China 200030

Plant Address: Baishou Road, North District of Xuan Zhou Economic Development Zone, Xuan Cheng City, Anhui Province, China

Tel: +86 21 6487 9251

Email: yorichen@sanezen.com

Official Website: www.sanezenrubber.com