In industrial applications where thermal management is critical, material failure is not an option. This technical article explores the performance envelope of the Sanesil SR1200UTH series, a premium grade of high temperature resistant silicone rubber. We will examine the common challenges faced by industries operating above 250°C, benchmark the SR1200UTH against typical industry performance standards, and delve into the technical data that validates its exceptional thermal stability, notably its ability to withstand continuous exposure up to 315°C and demonstrate remarkable performance retention after prolonged aging at 300°C, a key characteristic of advanced thermally resistant silicone rubber. Furthermore, we will highlight the manufacturing excellence and quality assurance processes at our state-of-the-art production facility in Anhui, China, where we operate as leading Special silicone rubber Manufacturers China and reliable Special silicone rubber Suppliers China, which underpin the consistent quality of this advanced customized silicone rubber compound

1.The High-Temperature Operating Frontier

The relentless push for higher efficiency, greater power density, and more compact designs across industries—from electric vehicles and renewable energy systems to industrial automation and consumer appliances—has irrevocably shifted operational temperatures upward. Components such as gaskets, seals, cable insulation, and roller coverings are increasingly subjected to thermal environments that push conventional elastomers beyond their limits.

Standard silicone rubber compound (VMQ), while offering a wider temperature range than organic rubbers, typically see their long-term service ceiling capped at approximately 200-250°C. Beyond this point, polymer chains begin to degrade more rapidly through processes like oxidation and chain scission, leading to a catastrophic loss of mechanical properties: the material hardens, becomes brittle, and loses its elastomeric functionality, resulting in seal failure, insulation breakdown, and ultimately, equipment downtime.

The industry, therefore, faces a clear need for advanced silicone rubber compounds that not only survive but also maintain functional integrity in the 250°C to 300°C+ range. The Sanesil SR1200UTH series, a Customized Special silicone rubber engineered specifically to meet this challenge, is a prime example of innovation from expert Special silicone rubber Manufacturers.

2. Market Context: Typical High Temperature resistant Silicone rubber Performance

To appreciate the advancement represented by the SR1200UTH series, it is essential to understand the baseline performance of commonly available “high-temperature” silicones.

• Long-Term Thermal Endurance: Many products claim high temperature resistance, but this is often a short-term or intermittent rating. For reliable long-term service (thousands of hours), a conservative upper limit of 250°C is common for many standard materials. Performance retention after extended aging at temperatures like 300°C is a key differentiator that is not universally offered by many silicone rubber suppliers.

• The Issue of Secondary Vulcanization: A significant operational drawback of many high-performance silicone compounds is the requirement for post-curing or secondary vulcanization. This is an additional heat treatment step (e.g., 4 hours at 200°C) after the initial molding process. It is performed to drive off volatile by-products from the peroxide cure system, which stabilizes properties and improves compression set resistance. However, it adds considerable time, energy cost, and logistical complexity to the manufacturing process for partners and Custom silicone rubber Suppliers.

• Performance Decay Under Thermal Stress: Even specialized thermally resistant silicone rubber can exhibit significant property degradation. A 30-50% loss in tensile strength and elongation at break after aging at 250°C for 168 hours (7 days) is not uncommon. At 300°C, many materials would become unusable within a similar timeframe.

3. Sanesil SR1200UTH: A Data-Driven Analysis of Superiority

The SR1200UTH series is formulated to directly address the limitations of standard offerings. Its technical data sheet (TDS) provides compelling evidence of its superior capabilities as a High temperature resistant silicone rubber.

3.1. Core Advantages at a Glance

• Exceptional Heat Resistance: Rated for continuous service up to 315°C, solidifying its position as a top-tier thermally resistant silicone rubber.

• No Secondary Vulcanization Required: This is a major processing advantage for our customers and Custom silicone rubber Suppliers, eliminating an entire production step, reducing energy consumption, and accelerating throughput.

• Excellent Raw Rubber Strength: Facilitates easier processing and handling before vulcanization, improving production yields for this customized silicone rubber compound .

• Good Thermal Stability: The data confirms minimal structural degradation over time at high temperatures, a hallmark of reliable high temperature silicone rubber.

• Long Shelf Life: Stable raw compound storage properties ensure consistency for end-users.

4. Foundation of Quality: Our Manufacturing and Technical Capabilities

A superior formulation is only as good as the consistency with which it is produced. The reliability of the SR1200UTH series is rooted in the advanced manufacturing capabilities of our facility in Xuan Cheng City, Anhui Province, where we operate as a dedicated Thermally resistant silicone manufacturer and High temperature resistant silicone rubber manufacturer.

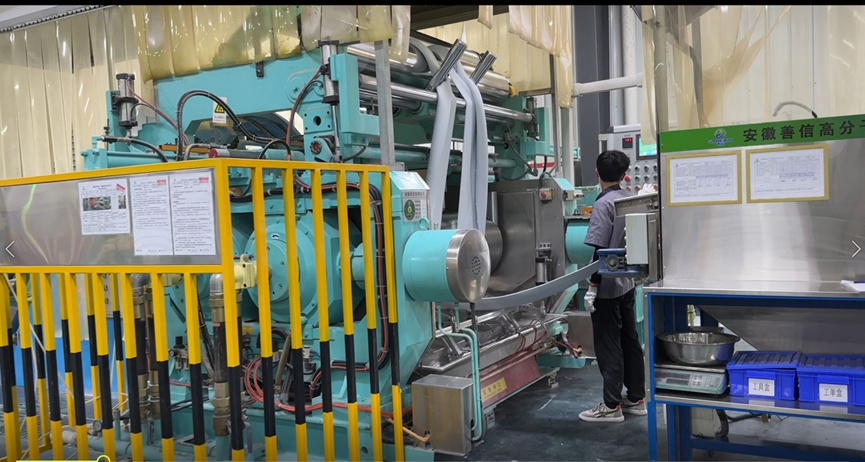

• State-of-the-Art Facility: Our plant is equipped with modern compounding and mixing lines, ensuring precise control over every batch of this Special silicone rubber. We employ automated systems for weighing, mixing, and refining to eliminate human error and guarantee uniformity expected from leading Special silicone rubber Manufacturers China.

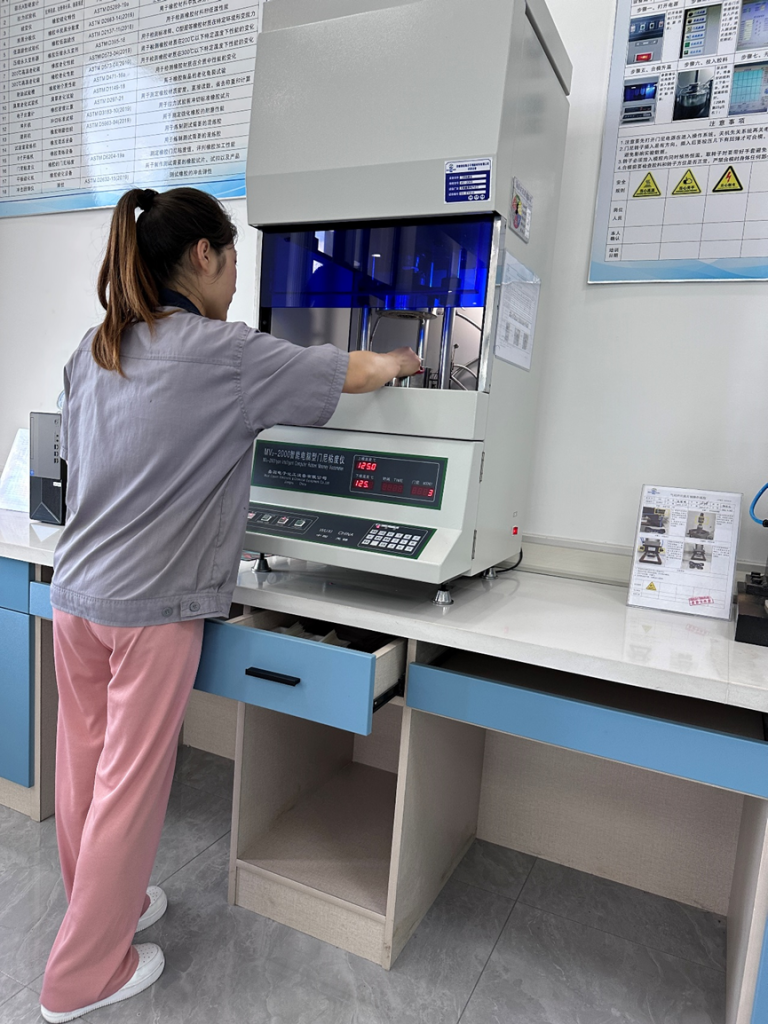

• Stringent Quality Control: From raw material inspection to final product testing, our QC protocols are rigorous. We utilize in-process testing and batch-by-batch analysis to ensure that every kilogram of SR1200UTH that leaves our facility meets the exacting specifications outlined in the TDS, a commitment shared by quality-focused Special silicone rubber Suppliers China.

• Technical Expertise: Our team of experienced chemists and engineers is dedicated to continuous improvement and provides expert technical support to our customers, helping to optimize processing parameters and application performance for this Customized Special silicone rubber.

5. Targeted Industry Applications

The combination of extreme heat resistance, processing ease, and proven longevity makes the SR1200UTH series ideal for a range of critical applications requiring a dependable High temperature resistant silicone rubber:

• Electric Vehicle (EV) & Battery Technology: Battery pack seals, gaskets for electric motors and power electronics, and insulation for high-voltage cables where thermal runaway protection and long-term heat exposure are concerns.

• Industrial Sealing & Gaskets: Seals for industrial ovens, furnaces, hot oil systems, and chemical processing equipment requiring resistance to continuous high heat.

• Wire & Cable: Insulation and jacketing for UL/CSA recognized heat-resistant cables (e.g., UL 1441, UL 3035), heater leads, and high-temperature wiring harnesses.

• Consumer Appliances & Tools: Seals and components for high-end steam ovens, boilers, industrial-grade hair styling tools, and other appliances operating at peak temperatures.

• Industrial Rollers: Coverings for hot stamping, laminating, and printing rollers where resilience against heat and pressure is essential.

6. Product Portfolio and Selection Guide

The SR1200UTH series is available in a range of Shore A hardnesses (from 40 to 80) to suit various application requirements for soft sealing or rigid structural components. This variety underscores our capability as a provider of Customized silicone rubber compound . The key variants are:

• SR1240UTH: Softer compound, excellent for complex seals requiring easy compression.

• SR1260UTH: A versatile, medium-hardness grade with an excellent balance of strength, tear resistance, and compression set (as analyzed above).

• SR1270UTH & SR1280UTH: Firmer compounds designed for applications requiring high structural integrity and resistance to deformation under load.

Our technical team is available to assist in selecting the optimal grade for your specific needs.

7. Conclusion and Recommendation

In the challenging landscape of high-temperature engineering, material selection is paramount. The Sanesil SR1200UTH series represents a significant leap forward, offering proven, data-backed performance that exceeds the capabilities of standard high temperature resistant silicones. Its ability to operate continuously at 315°C, coupled with its exceptional retention of properties after prolonged aging at 300°C, provides engineers and designers with a reliable solution for their most demanding applications. This performance is what defines it as a superior thermally resistant silicone rubber.

When you factor in the significant processing advantage of no secondary vulcanization and the assurance of quality provided by our modern manufacturing infrastructure as a recognized High temperature resistant silicone rubber manufacturer, the SR1200UTH series presents a compelling value proposition.

We recommend evaluating the Sanesil SR1200UTH for any application where thermal stability, long-term reliability, and manufacturing efficiency are critical. As experienced Special silicone rubber Manufacturers, we are confident it will meet the stringent requirements of your most challenging projects.