In extremely low-temperature environments, traditional rubber materials commonly face technical challenges such as embrittlement, loss of elasticity, and sealing failure. Based on the technical data sheet (TDS) of Lixin Rubber’s NV series NBR/PVC rubber-plastic blends, this article provides an in-depth analysis of their performance under ultra-low temperature conditions. It systematically explains the comprehensive advantages of this material, which maintains excellent elasticity, ozone resistance, oil resistance, and mechanical strength even at a TR10 as low as -48°C. From a materials science perspective, the article analyzes the mechanism behind its low-temperature performance. Combined with specific application scenarios such as frozen logistics, cables for cold regions, automotive low-temperature components, and industrial pipelines, it offers comprehensive material selection guidelines and engineering solutions. It aims to provide reliable technical reference for engineers and decision-makers facing low-temperature environmental challenges, particularly those seeking low temperature resistant rubber solutions from NBR PVC rubber blends Manufacturers for applications like NBR PVC blends for cold weather sealing and other freeze resistant rubber compound needs.

Chapter 1: Material Challenges and Industry Pain Points in Extreme Low-Temperature Environments

1.1 Low-Temperature Embrittlement: The Common Failure Mode of Traditional Rubber Materials

When the ambient temperature drops below zero, especially below -20°C, most elastomer materials begin to undergo a glass transition. Molecular chain segment movement freezes, the material gradually loses elasticity, manifesting as a sharp increase in hardness, a drastic drop in elongation, and worsened impact toughness. For components relying on elasticity to maintain sealing pressure, such as O-rings, gaskets, and sealing strips, this embrittlement directly leads to leakage risks. Under dynamic loads, such as in low-temperature conveyor belts or vehicle suspension bushings in cold regions, embrittlement is more likely to cause cracking or even fracture.

Industry data shows that in industrial equipment failures in cold regions (such as Northern Europe, Canada, Northeast China), approximately 30% of unplanned downtime is related to the low-temperature failure of seals or rubber components. The embrittlement temperature of ordinary nitrile rubber (NBR), the traditional mainstay oil-resistant material, is typically between -20°C and -30°C, unable to meet the demanding conditions below -40°C. While silicone rubber has a wider temperature range, its mechanical strength, wear resistance, and oil resistance are often insufficient, and it comes at a high cost.

1.2 The Combined Effect of Low Temperature and Complex Environments

In real application scenarios, low temperature is often not an isolated factor. It frequently coexists with one or more of the following environmental stresses:

- Medium Compatibility Challenges: Contact with refrigerating machine oil, hydraulic oil, fuel, etc., is still required.

- Ozone and Ultraviolet (UV) Light: Higher ozone concentrations at high altitudes, polar regions, or around industrial areas, synergistically accelerating material aging with low temperature.

- Dynamic Mechanical Stress: Equipment start-stop cycles, vibration, and periodic deformation require the material to maintain fatigue toughness at low temperatures.

- Installation and Maintenance Limitations: The extremely high cost of replacing components in harsh cold environments places higher demands on material lifespan and reliability.

Therefore, an ideal low-temperature rubber material should not only be “cold-resistant” but also maintain its core functionalities at low temperatures—elastic recovery force, sealing force, insulation properties, and medium resistance. This is crucial for developing a rubber material for sealing in cryogenic applications.

Chapter 2: Decrypting the Low-Temperature Performance of NBR/PVC Blends: The Science Behind the Data

Lixin Rubber’s NV series (NV2355, NV3355A, NV5090) achieves complementary advantages between rubber’s elasticity and plastic’s rigidity/weather resistance through precise NBR and PVC polymer alloying technology. Its exceptional low-temperature performance is not accidental but stems from its unique micro-phase structure and formulation design.

2.1 Interpretation of Key Low-Temperature Indicators: The Significance of TR10

The “Low Temperature Retraction Property TR10” in the TDS is a core indicator for measuring rubber’s low-temperature elasticity. It represents the temperature at which a rubber specimen recovers 10% of its original length after cooling and stretching. A lower TR10 value indicates a stronger ability of the material to maintain elasticity at low temperatures.

- NV2355: TR10 = -48°C

- NV3355A: TR10 = -42°C

- NV5090: TR10 = -43°C

Technical Interpretation: NV2355’s TR10 of -48°C means that even in extreme cold environments close to -50°C, this material can still effectively perform elastic recovery, far superior to ordinary NBR (around -25°C) and many general-purpose synthetic rubbers. This performance benefits from the introduction of the PVC phase, which inhibits the tendency of NBR molecular chains to crystallize at low temperatures. Simultaneously, the carefully selected Sanepar series plasticizers in the formulation have good low-temperature permanence, are not prone to migration or bleeding at low temperatures, thereby maintaining the flexibility of the molecular chains over the long term. This makes it an excellent low temperature rubber material with high compression set resistance.

2.2 Retention of Mechanical Properties at Low Temperatures

It is inevitable for materials to harden at low temperatures, but the key is the degree of hardening and whether it is accompanied by brittleness. While maintaining moderate low-temperature hardness, the NV series exhibits excellent toughness.

- Hardness (Shore A): NV2355/NV3355A is 65A, NV5090 is 55A. This mid-to-high hardness spectrum ensures sufficient rigidity at low temperatures to resist crushing and maintain sealing contact pressure.

- Tensile Strength and Tear Strength: NV5090’s tear strength is as high as 14.84 Kg/cm², combined with its 650% elongation at break, forming a “high-strength, high-toughness” combination. This characteristic can effectively prevent the initiation and propagation of cracks under low-temperature impact or accidental scraping, exemplifying High tear strength rubber for cold weather seals.

- M100 Modulus (Stress at 100% elongation): NV5090’s M100 is 2.27 Kg/cm². A higher modulus means the material can provide greater recovery force at the same deformation, which is crucial for the durability of low-temperature seals.

2.3 Synergistic Advantages of Low Temperature and Resistance to Environmental Stresses

TDS data reveals the NV series’ ability to withstand other harsh conditions on top of its low-temperature base:

- Excellent Ozone Resistance (80 pphm, 40°C, 120 hours, no cracks): Ozone is one of the aging agents for rubber in outdoor low-temperature environments (e.g., high-latitude regions). The PVC phase provides a natural ozone barrier, preventing the blend from cracking even under high ozone concentration and tensile strain, ensuring the integrity of components for long-term outdoor use in cold regions. This is key for ozone resistant rubber for outdoor low temperature use.

- Outstanding Oil and Fuel Resistance:

- In ASTM No. 1 Oil (100°C, 70h), the volume change rate of NV2355 is only -10.24%. At low temperatures, oil viscosity increases, but the material’s extremely low swell ensures dimensional stability, preventing sealing failure caused by shrinkage or expansion.

- In Fuel C (40°C, 48h), the volume expansion rate is controlled within +38.89%. This is valuable for fuel system lines and seals used in cold regions, avoiding material softening and strength loss caused by fuel penetration. This defines an Oil resistant NBR PVC blend for extreme cold.

- Good Compression Set: NV2355’s compression set is 39.74% at 100°C for 70 hours. This indicator indirectly reflects the material’s ability to recover elastically after long-term compression (e.g., sealing gaskets). A lower compression set means that after experiencing low-temperature cycles, the seal can still recover its shape reasonably well, maintaining sealing force.

Chapter 3: In-Depth Analysis of Four Application Scenarios for Harsh Low-Temperature Environments

3.1 Frozen Chain Logistics and Cold Chain Equipment Sealing

Application Components: Cold storage door seals, refrigerated truck/container door seals, freezer display cabinet seals, compressor sealing gaskets.

Operational Challenges: Long-term exposure to -25°C to -40°C environments, frequent temperature cycling, freezing/thawing processes, potential contact with condensation or slight grease.

Solution:

- Material Selection: NV2355 (TR10 -48°C) is recommended. Its excellent low-temperature elasticity ensures door seals remain soft and conforming even in severe cold, preventing cold air leakage. Superior ozone resistance adapts to environmental aging outside cold storage. It is an ideal rubber compound for freezer gaskets and seals.

- Performance Assurance: High tear strength (11.56 Kg/cm²) prevents seals from being scratched or torn by door corners during frequent opening/closing. Good compression set ensures seals are less prone to permanent indentations after long-term use, maintaining sealing effectiveness. This directly addresses the need for rubber material for freezer door seals in cold storage.

3.2 Cable Jackets and Insulation for Outdoor Use in Cold Regions

Application Components: Power transmission lines in cold regions, mining cables, outdoor communication cables, cable jackets for new energy (wind/solar) stations.

Operational Challenges: Temperatures below -40°C, large day-night temperature differences, strong UV radiation, wind/snow/ice abrasion, potential ozone erosion.

Solution:

- Material Selection: NV3355A or NV5090. Both offer good low-temperature toughness (TR10 -42°C/-43°C) and excellent weather/ozone resistance. NV5090’s higher elongation (650%) provides a greater safety margin for cable laying and bending at low temperatures, making it a suitable cable jacket material for extreme cold environments and even NBR PVC elastomer for arctic cable insulation.

- Performance Assurance: The material’s inherent flame retardancy (passing relevant standard tests) and anti-static properties enhance cable safety in special cold-region environments. The smooth surface characteristic (mentioned in TDS) facilitates extrusion processing, forming a dense, smooth jacket that effectively blocks moisture and humidity ingress, preventing cable damage caused by internal moisture freezing at low temperatures.

3.3 Automotive Cold Starts and Cold Region Driving Systems

Application Components: Engine low-temperature sealing gaskets, outer layer of fuel lines, brake system dust boots, suspension system bushings, door/window seals.

Operational Challenges: Cold starts below -30°C in winter, large temperature gradients in the engine bay, contact with various lubricants and fuels, accompanied by vibration and mechanical stress.

Solution:

- Material Selection: For static seals (e.g., gaskets), NV2355 can be chosen. For dynamic components (e.g., bushings, dust boots), NV5090 with better toughness is an option, serving as low temperature resistant rubber for automotive cold start seals.

- Performance Assurance:

- Low-Temperature Sealing: The TR10 indicator ensures components remain flexible even on extremely cold mornings, guaranteeing sealing effectiveness during the first cold start.

- Oil and Fuel Resistance: Stable performance in ASTM oils and Fuel C prevents excessive swelling or softening failure of lines or seals in low-temperature oils.

- Heat Aging Resistance: TDS data shows good hardness change and strength retention after aging at 100°C for 70 hours, meaning the material can withstand the rapid temperature rise from extreme cold to normal engine operation. This is beneficial for NBR PVC blend for fuel line protection in cold climates.

3.4 Low-Temperature Industrial Processes and Pipeline Systems

Application Components: LNG pipeline flange gaskets, seals for low-temperature liquid transfer pumps, seals for chemical low-temperature reactors, seals for air separation equipment.

Operational Challenges: Cryogenic environments (-50°C to -160°C or lower), high pressure, media may be permeable or corrosive.

Solution:

- Material Selection: NV2355’s TR10 (-48°C) makes it a candidate material for applications above -50°C in fields like LNG. For even lower temperatures, the possibility of customized formulations can be explored, targeting rubber material for sealing in cryogenic applications.

- Performance Assurance: The material’s high strength and low compression set are the foundation for flange sealing reliability. Good chemical resistance (stemming from NBR and PVC synergy) can address challenges posed by certain chemical media at low temperatures. Compared to pure plastic sealing materials like PTFE, NBR/PVC blends offer better elastic compensation capability and installation convenience. This meets the demand for low temperature rubber for industrial gaskets.

Chapter 4: Competitive Comparative Analysis with Mainstream Low-Temperature Elastomers

To highlight the comprehensive advantages of the NV series NBR/PVC in low-temperature applications, we compare it with several commonly used low-temperature rubber materials:

| Performance Dimension | NBR/PVC (Lixin NV2355) | Ordinary NBR | Silicone Rubber (VMQ) | Fluoro-silicone Rubber (FVMQ) | Neoprene (CR) |

| Low-Temperature Brittleness | TR10 ≈ -48°C | TR10 ≈ -20°C to -30°C | TR10 ≈ -60°C to -100°C | TR10 ≈ below -60°C | TR10 ≈ around -40°C |

| Oil Resistance | Excellent (Low change in ASTM #1 oil) | Excellent | Poor | Good-Excellent | Moderate |

| Ozone/Weather Resistance | Excellent (No cracks in 120h) | Poor | Excellent | Excellent | Good |

| Mechanical Strength | High (Tear strength >11 Kg/cm²) | High | Low | Low-Moderate | Moderate |

| Abrasion Resistance | Excellent | Good | Poor | Moderate | Good |

| Flame Retardancy | Excellent (PVC-based) | Poor | Poor (requires additives) | Moderate | Good (Self-extinguishing) |

| Cost Factor | Moderate, High Cost-Effectiveness | Low | High | Very High | Moderate |

Comparison Conclusion:

- vs. Ordinary NBR: The NV series achieves an overwhelming superiority in low-temperature range and weather resistance, compensating for NBR’s biggest weaknesses while fully inheriting or even optimizing core performances like oil resistance and strength.

- vs. Silicone/Fluoro-silicone Rubber: It shows significant advantages in oil resistance, mechanical strength, and abrasion resistance, with substantially lower cost. Although its low-temperature limit is not as low as silicone’s, within the broad low-temperature range above -50°C, it provides the best balance between functionality and cost, especially suitable for applications requiring simultaneous resistance to low temperature, oil media, and mechanical wear. It is an NBR PVC blend with high tear strength for cold weather.

- Comprehensive Positioning: Lixin’s NV series NBR/PVC does not pursue a single extreme low temperature but is committed to providing comprehensive, balanced, and reliable performance combination within a wide temperature range (-50°C to +100°C+), solving the “systemic problems” of most industrial low-temperature scenarios.

Chapter 5: Why Choose Lixin Rubber: Manufacturing Strength and Quality Assurance

Advanced material formulations require a powerful manufacturing system as backing to ensure high consistency from lab data to end-product performance. Located in Xuancheng, Anhui, China, the Lixin Rubber factory is the solid guarantee for the exceptional quality of the NV series NBR/PVC and other high-performance compound products. Our core competitiveness is rooted in the following five dimensions:

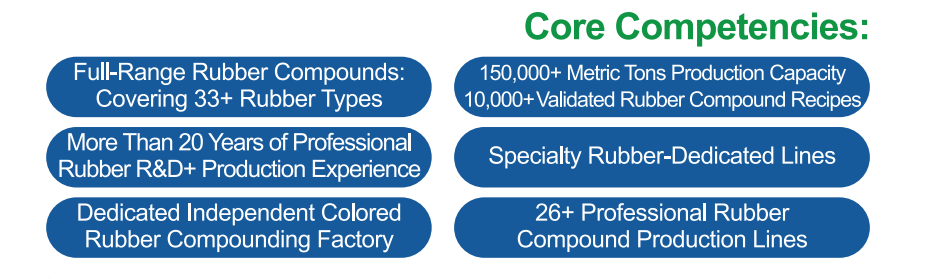

5.1 Scalability and Specialized Production Capability

- Annual capacity exceeding 150,000 tons: Strong production scale ensures we can stably and promptly meet global customer demands for large-volume orders, whether for standard or customized products.

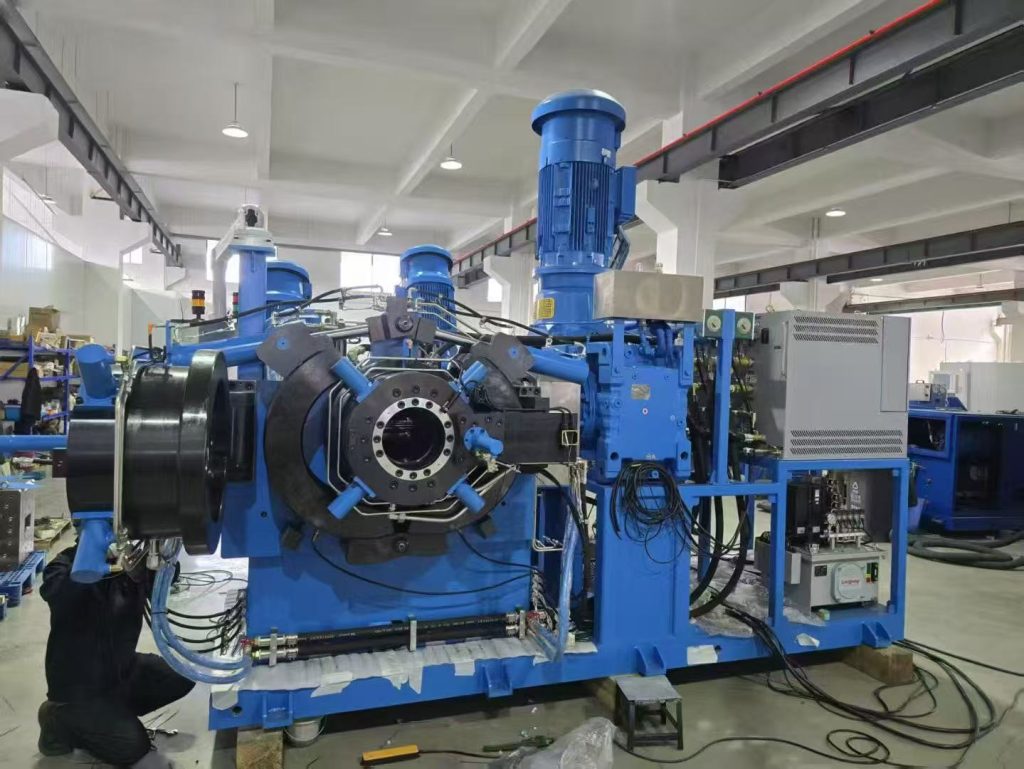

- Over 26 specialized production lines: Covering various processes like internal mixing, open milling, extrusion, and pelletizing, dedicated lines ensure precise process control and zero risk of cross-contamination.

- Specialized independent color compound factory: For special applications requiring color (e.g., consumer goods, medical devices, automotive interior parts), we have an independent color compound factory, eliminating color deviation and contamination from the source, ensuring bright colors and batch consistency.

5.2 Profound Technical Accumulation and Formulation Library

- Over 20 years of specialized R&D and production experience: Deeply cultivating the rubber materials field for over two decades, with profound understanding and rich practical experience in the properties, processability, and blending technology of various rubbers.

- Full-range rubber formulation coverage: The product system covers over 33 rubber types including NBR, PVC, EPDM, silicone rubber, and fluorocarbon rubber, enabling us to provide cross-material comparison, selection, and one-stop solutions for customers, positioning us among Full range of rubber compound Manufacturers China.

- Over 10,000 verified mature formulations: A vast formulation database is the foundation for rapid response and precise customization. Whether for ultra-low temperature, ultra-high wear resistance, or special chemical resistance needs, we can quickly match or optimize the most suitable solution from a massive pool of validated formulas, embodying the role of Custom Rubber compound Manufacturers.

5.3 Extreme Quality Control Throughout the Process

From raw material incoming inspection to online monitoring during production (temperature, time, energy input), to full-performance testing of final products (rheology, physical mechanics, aging, medium resistance, etc.), we have established a strict quality control system aligned with automotive industry standards. Every batch of NV series products shipped comes with complete test data, ensuring its performance matches the published TDS data, giving customers peace of mind.

5.4 Agile Response to Customization Development

Based on a powerful R&D platform and production capability, we not only provide standard grades like NV2355, NV3355A, NV5090 but can also quickly adjust and optimize formulations according to customers’ specific low-temperature conditions, media environments, and processing techniques (e.g., extrusion speed, curing conditions), offering “tailor-made” material solutions.

Chapter 6: Conclusion

Extreme low-temperature environments pose severe challenges to elastomer materials. Materials with single outstanding properties often struggle to cope with real-world conditions characterized by complexity and multiple concurrent stresses. Lixin Rubber’s NV series NBR/PVC rubber-plastic blends, With its scientific polymer alloy design, successfully integrate exceptional low-temperature elasticity (TR10 as low as -48°C), powerful oil and fuel resistance, outstanding ozone and weather resistance, and high mechanical strength.

It breaks through the performance barriers traditional materials face against low temperature, oil contamination, and outdoor aging, providing reliable, data-verified solutions for critical areas such as freezer equipment sealing, cold-region cable jacketing, automotive low-temperature components, and industrial low-temperature pipelines. Compared to high-priced materials like silicone rubber, its demonstrated high cost-effectiveness makes the application of high-performance low-temperature materials possible in a wider range of projects.

Choosing Lixin Rubber means not only selecting a high-performance low-temperature material but also choosing a strategic partner with an annual manufacturing capacity of 150,000+ tons, over ten thousand mature formulation technologies, a complete independent color compound production capability, and a strict quality control system run through the entire process. Our modern factory in Xuancheng, Anhui, is always ready to translate laboratory innovation into stable and reliable products in our customers’ hands. We are committed to working with customers to overcome sealing and insulation challenges in extreme environments, driving the reliability and competitiveness of end products through material innovation.

We welcome engineers, purchasers, and decision-makers facing low-temperature challenges to contact us to obtain the full NV series Technical Data Sheet (TDS) or to discuss your specific application needs and customization possibilities. Whether you are looking for NBR PVC rubber blends Suppliers or partners for NBR PVC blend for low temperature sealing applications, we are here to provide solutions.