Introduction: When Material Performance Meets Industry Ceilings

In an era of electric vehicles, space exploration, and smart manufacturing, the demands on core foundational materials—especially high-performance elastomers like silicone rubber and specialized compounds—are being constantly redefined. Traditional material systems are showing their limitations: standard silicone rubber offers excellent elasticity but fails catastrophically in the presence of fuels and lubricating oils; fluoroelastomer (FKM) boasts superior chemical resistance but is hampered by poor low-temperature elasticity and high compression set, making it a challenging choice for dynamic sealing applications.

The industry urgently needs a versatile material that combines the best of all worlds. It must remain flexible at -60°C, maintain its form at 230°C, withstand aggressive chemical media, and offer excellent processability and long service life. Fluorosilicone Rubber (FVMQ) is the answer to this call. The Sanesil FS 8200 U and FS 2200 U series from SaneZen represent the latest evolution of this answer, becoming a key enabler in solving sealing dilemmas for high-end manufacturing. As leading Fluorosilicone rubber Manufacturers and Fluorosilicone rubber Suppliers, we provide high-quality silicone rubber compound solutions.

I. The Technological Edge: Performance Breakthroughs and Design Philosophy of Sanesil FVMQ

SaneZen’s R&D team, with deep market insight, has systematically optimized Fluorosilicone Rubber through advanced polymer synthesis and nano-composite technology. Their latest achievements are embodied in the two main product series: FS 8200 U (Extrusion Grade) and FS 2200 U (Molding/General Grade).

1. Ultra-Low Compression Set for Long-Term Sealing Life

Compression set is the “lifeline” metric determining a seal’s long-term effectiveness. Material relaxation and permanent deformation under high temperatures can lead directly to leakage. The Sanesil FS 2200 U series achieves an industry-leading breakthrough in this property. The data is impressive: after rigorous testing at 177°C for 22 hours, the compression set values for this series remain in an exceptionally low range of 6.2% – 7.5% (ASTM D395 Method A). This means that even under continuous high temperature and pressure, SaneZen seals maintain excellent resilience, ensuring reliable performance for years, significantly extending equipment maintenance cycles and service life.

2. Exceptional Fluid Resistance and Environmental Adaptability

The core value of FVMQ lies in its unique fluid resistance. SaneZen products undergo rigorous testing in various standard fluids, demonstrating comprehensive and balanced resistance:

- Fuel/Oil Resistance: After 70 hours of immersion in Fuel B (FS8200U) and Fuel C (FS2200U), volume swell is controlled at an excellent level of +15% to +25%, far superior to standard rubbers, ensuring dimensional stability in critical automotive applications like fuel systems and engine sumps.

- Polar Solvent & High-Temperature Oil Resistance: In 903# oil, the volume change for FS2200U is as low as +2.1% to +3.5% with minimal hardness change, proving outstanding resistance to various synthetic and hydraulic oils.

This comprehensive chemical resistance allows it to handle the complex chemical environments found in petrochemical and automotive industries.

Factory entrance

3. Broad Hardness Range and Superior Mechanical Properties

To meet the softness/hardness requirements of different applications, Sanezen offers an extensive product matrix. The FS 2200 U series provides a complete hardness selection from 30° to 79° (Shore A), while the FS 8200 U series covers the common range of 50° to 80°. More remarkably, even at low hardness (30°), the tensile strength remains close to 10 MPa, and at high hardness, it maintains an elongation at break of over 320% (FS8280U). This combination of high strength and high elasticity ensures seals are resistant to tearing and damage during installation and use.

4. Optimized Processing and Green Manufacturing

The FS 8200 U series features good extrusion performance with a smooth surface, making it ideal for producing complex profiles like sealing strips and tubes. The FS 2200 U series is easy to process and pigment, possesses high rebound resilience, and is suitable for molded O-rings, gaskets, diaphragms, etc. Both product lines utilize efficient peroxide or platinum cure systems, ensuring high vulcanization efficiency conducive to energy saving and green manufacturing.

Factory gate

Cleanroom, factory workshop

Silicone rubber compound

Silicone rubber compound

II. Application Deep Dive: How Sanesil FVMQ Empowers Core Industry Upgrades

Application 1: New Energy Vehicles (NEVs) – Ensuring Safety and Performance of the Powertrain

The “lifeblood” of an EV is high-voltage current and various demanding fluids. Sanesil FVMQ is the ideal choice for:

- Battery Pack Sealing: Its exceptional resistance to coolants (especially new low-conductivity types) and flame retardant properties (can achieve UL94 V-0) provide safe and reliable sealing for battery modules, preventing coolant leakage-induced short circuits and acting as a barrier during early-stage thermal runaway.

- E-Drive System Sealing: Resistance to high-temperature gear oil (up to 230°C) and low compression set make it perfect for rotary shaft seals and static seals in motors and reducers, handling harsh conditions of high speed and temperature.

- Charging Connector Sealing: Good insulation and aging resistance ensure the safety and durability of high-voltage charging interfaces.

Application 2: Aerospace – A Material Pioneer Conquering Extreme Environments

At high altitudes and in the depths of space, material failure is not an option. With its wide operating temperature range (-60~230℃) and outstanding resistance to aviation fuels and hydraulic oils, Sanesil FVMQ is widely used in:

- Various oil circuit seals in aircraft engines.

- Sealing strips for doors and windows, ensuring cabin pressure integrity.

- O-rings and gaskets in spacecraft hydraulic and fuel systems.

Application 3: High-End Industrial Equipment – The Silent Guardian of Process Stability

In semiconductors, petrochemicals, and military industries, Sanesil FVMQ is equally indispensable.

- Semiconductor Manufacturing: Used for pump diaphragms and tubing seals handling high-purity chemicals, its low extractables prevent contamination of ultra-pure media.

- Petrochemicals: Used in seals for oilfield equipment and refinery installations exposed to crude oil, diesel, and natural gas, resisting corrosion from media like hydrogen sulfide.

- Military Equipment: Used in fuel and lubrication systems of tanks, armored vehicles, and other heavy equipment, meeting the high-reliability requirements for operation in extreme field environments.

III. SaneZen: Starting with Materials, Committed to Solutions

A Leading Domestic Dust-Free Factory for Silicone Compound and Colored Stock

The exceptional performance described is underpinned by a robust manufacturing system. SaneZen operates one of China’s most technically advanced dust-free factories for silicone rubber compound and colored stock. As professional Fluorosilicone rubber Manufacturers China and Fluorosonicone rubber Suppliers China, we utilize fully automated production lines and intelligent control systems. The entire process—from raw polymer compounding, filler integration, and mixing to sheeting and packaging—is conducted within a Class 10,000 cleanroom environment. This ensures every batch of product achieves exceptionally high cleanliness, color consistency, and performance stability. Our technical team, led by experienced polymer experts, possesses strong independent R&D and customization capabilities, enabling rapid response to specific customer needs for Customized Fluorosilicone rubber and providing full-process technical support from material selection and formula debugging to application testing.

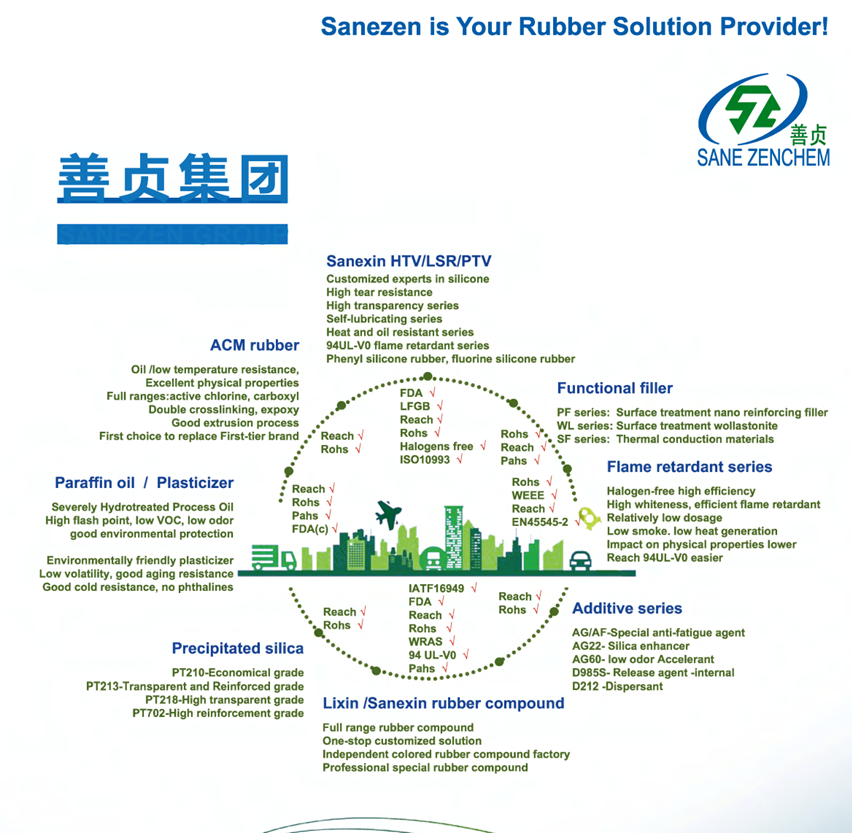

A One-Stop Elastomer Solutions Provider

SaneZen’s strategic vision extends beyond silicone. To provide more comprehensive, integrated value to our customers, we have consolidated resources across the supply chain:

- Anhui Lixin Rubber Compound Factory & Anhui Shengxin Compound Factory: These facilities focus on producing high-performance rubber compounds (such as FKM, HNBR, EPDM, etc.), widely used in automotive parts, oil seals, tracks, and vibration damping products. They perfectly complement our silicone product lines.

Full range of products

Full range of Rubber compound

Wide range of rubber chemical and rubber filler

- Supporting Specialty Additives and Fillers: We independently develop and produce high-performance fillers, halogen-free eco-friendly flame retardants, and specialty rubber additives. Particularly noteworthy is our fully bio-based filler additive for tires, sourced from renewable raw materials, helping the tire industry achieve a green, low-carbon, high-performance upgrade.

This means that choosing SaneZen grants you not just a premium Fluorosilicone rubber material, but also access to a powerful technical backbone and a one-stop solution platform covering a wide range of elastomers and additives. We can collaborate on design from the source, helping you optimize product structure, enhance performance, and reduce costs, facing future challenges together.

Conclusion: Partner with SaneZen to Define the New Standard in Sealing

Times change, challenges evolve, but the pursuit of reliability, durability, and ultimate performance remains constant. Leveraging innovative FVMQ materials as the cornerstone, supported by advanced manufacturing and comprehensive industry chain integration, SaneZen is partnering with leaders across various sectors to redefine the standards of sealing reliability.

We sincerely invite you to present your most demanding application challenges to us. Our engineering team is ready to provide free technical consultation, sample testing, and Customized Fluorosilicone rubber solutions. Let’s explore the limitless possibilities of material technology together and transform your innovative designs into exceptional products that stand the test of time.

Take action now, contact us:

Website: www.sanezenrubber.com

Tel: +86-13671641995

Email: yorichen@sanezen.com

Plant Address: Baishou Road, North District, Xuanzhou Economic Development Zone, Xuancheng City, Anhui Province, China.

Commercial Address: Rooms 1606-1608, Boda Commercial Buildings, No. 11 Puhuitang Road, Xuhui District, Shanghai, China 200030

As one of the leading Fluorosilicone rubber Manufacturers and Fluorosilicone rubber Suppliers with our own Fluorosilicone rubber Factory in China, we are committed to providing top-quality silicone rubber solutions for global customers.