Introduction: When Rubber Meets Thermal Management – A Long-Overlooked Performance Bottleneck

Inside high-speed rotating truck and bus tires, temperatures silently climb above 120°C; on the surface of repeatedly punctured medical stoppers, tiny fragments may enter the patient’s bloodstream with the medication. These seemingly unrelated scenarios point to two long-standing core challenges in the rubber industry: material aging and failure caused by heat accumulation, and insufficient durability under dynamic stress or in chemical environments. Heat is not just wasted energy; it is a catalyst for material degradation, directly impacting product safety, lifespan, and reliability.

The RS925 Thermally Conductive Fine Silica, developed by the SaneZen Group Innovation Center, is a transformative solution born to address these challenges. It is not merely a filler but a functional material platform designed to redefine the performance matrix of rubber compounds. This article, based on rigorous experimental data, will provide an in-depth analysis of the outstanding performance of RS925 in solving industry pain points and enhancing overall product performance, while also exploring its broad application prospects.

Chapter 1: Deep Analysis of Market Pain Points – The Dual Challenge of Heat and Durability

1.1 The Tire Industry: Heat Buildup as the “Invisible Killer” of Performance and Safety

For Truck and Bus Radial (TBR) tires, under prolonged, high-load conditions, heat generated internally from deformation cannot dissipate quickly enough, leading to continuously rising temperatures. This heat accumulation triggers a chain reaction:

- Accelerated Compound Aging: High temperatures significantly promote rubber oxidation and cleavage, causing a sharp decline in mechanical properties (like tensile strength and elasticity), leading to hardening and cracking.

- Risk of Structural Delamination: Differences in the thermal expansion coefficients of various compound components are amplified by heat, increasing the risk of separation, a key factor in blowouts.

- Increased Rolling Resistance: The dynamic hysteresis loss of the compound rises at high temperatures, manifesting as increased rolling resistance, directly leading to higher fuel consumption for vehicles.

Traditional solutions often focus on optimizing formulations to reduce heat generation but usually compromise on key properties like abrasion and tear resistance. The market urgently needs a material that can fundamentally improve heat dissipation from the source without sacrificing, and even while enhancing, other properties. This is precisely where a High Durability Tire Compound Additive like RS925 shows its value, and why finding a reliable Rubber filler supplier China or Rubber filler manufacturer China offering such advanced solutions is crucial.

1.2 Medical Packaging Industry: Stringent Requirements for Chemical Inertness and Mechanical Reliability

Medical halogenated butyl rubber stoppers are the last line of defense for pharmaceuticals, and their reliability is directly related to drug safety. The industry’s pain points are clear:

- Coring and Fragmentation: If the stopper material lacks sufficient abrasion resistance, tiny particles generated during multiple syringe punctures can contaminate the drug solution, posing a significant clinical risk.

- Adsorption and Reaction: Certain components in the stopper may adsorb or chemically react with specific drugs (especially proteins and highly active solutions), affecting drug efficacy stability.

Cleanliness and Consistency: Any impurities or poor dispersion can become sources of contamination or performance weak points.

Therefore, stopper materials must provide excellent chemical inertness (high purity) while also offering outstanding reinforcement and abrasion resistance. This presents a near-contradictory high demand on fillers: they must be highly pure and chemically inert, yet effectively enhance physical properties. This creates a specific need for High Purity Silica for Medical Stoppers.

Chapter 2: RS925 Thermally Conductive Fine Silica – An Innovative Material Designed to Solve the Dilemma

RS925 is not a simple substitute for ordinary silica. It is a functional specialty silica that integrates high thermal conductivity with high-strength reinforcement through precise surface design and structural control.

Core Design Philosophy: While maintaining the excellent reinforcing effect of nano-silica, RS925 builds efficient heat conduction pathways within and between particles. This allows heat generated inside the rubber composite to be dissipated quickly and uniformly, fundamentally lowering the material’s operating temperature and delaying the thermal aging process.

Core Product Traits:

- High Thermal Conduction Network: Unique surface treatment and morphology control facilitate the formation of a heat conduction network within the rubber matrix.

- Excellent Dispersibility: Optimized surface characteristics ensure good dispersion even in high-viscosity rubber systems, a prerequisite for realizing its thermal and reinforcing efficacy. This makes it a Silica with Improved Dispersibility.

- High Chemical Purity and Inertness: Strict production process control makes it suitable for fields with stringent purity requirements, including medical applications, truly a Chemical Inert Filler for Elastomers.

Chapter 3: Evidence from Data – The Disruptive Performance of RS925 in TBR Tread Compounds

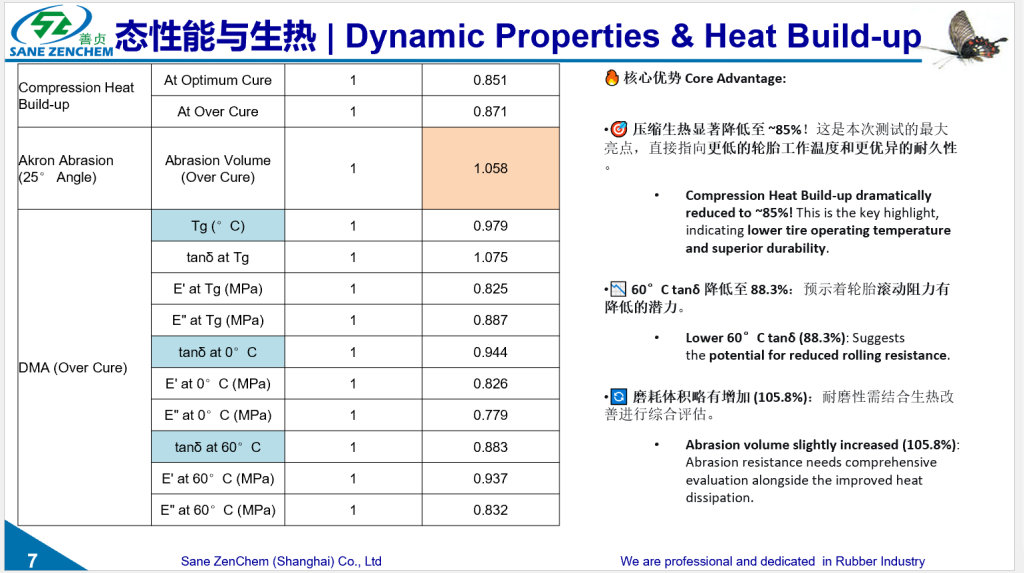

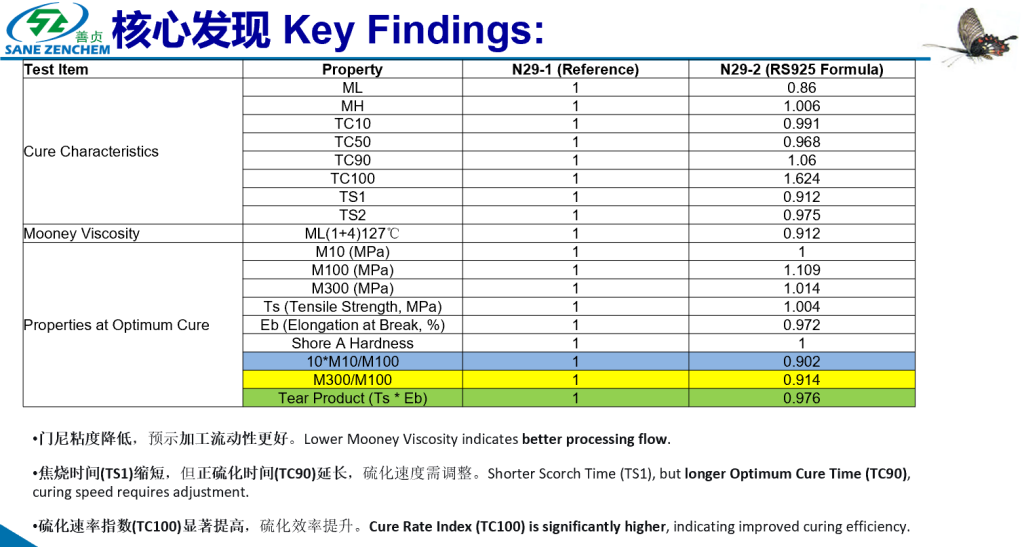

The following data is based on a lab-scale test where “10phr of RS925 replaced conventional silica equivalently,” with the reference formulation performance set at 100%. (Insertion prompt: Insert comparative charts/tables for “Compression Heat Build-up,” “Abrasion,” and “DIA (60°C tanδ)” data from the PPT here.) This data directly answers searches for a Formula to lower compression heat buildup in truck tires.

3.1 Revolutionary Heat Dissipation Efficiency: Compression Heat Build-up Dramatically Reduced by 15%

The most striking result in the experiment is that the compression heat build-up value of the compound with RS925 was only 85.1% (at optimum cure) of the reference formula. This means that under the same severe dynamic conditions, the internal temperature rise of the compound is significantly suppressed.

- Technical Implication: This directly verifies that the efficient thermal conduction network built by RS925 is functioning. Heat is removed faster from local high-strain areas, avoiding local heat accumulation.

- Customer Value:

- Enhanced Safety: Greatly reduces the risk of blowouts caused by compound degradation and adhesion failure due to overheating.

- Leap in Durability: The tire’s durability performance (e.g., shoulder separation, carcass fatigue) during long-haul travel is expected to improve significantly.

- Extended Lifespan: Lower operating temperatures mean slower oxidative aging, promising higher retread rates and overall service life. This makes RS925 a Low Heat Buildup Rubber Filler and a key component for Improving rolling resistance without sacrificing tread wear.

3.2 Optimization of Dynamic Mechanical Properties: Potential for Lower Rolling Resistance

Dynamic Mechanical Analysis (DMA) data shows that the tanδ value at 60°C for the RS925 compound was reduced to 88.3% of the reference formula. The tanδ at 60°C is a key indicator characterizing tire rolling resistance; its reduction suggests the potential for lower fuel consumption in the finished tire.

- Technical Implication: While reducing heat generation, it also decreases the compound’s hysteresis loss in the medium-to-high temperature range, indicating that RS925 optimizes filler-rubber interaction and reduces unnecessary energy dissipation.

- Customer Value: Provides tire manufacturers with a new material choice for designing the next generation of “green tires” with low rolling resistance and high durability, balancing energy saving and longevity. It is an effective Silica for Reducing Rolling Resistance.

3.3 Excellent Balance of Key Mechanical Properties

RS925’s contribution goes far beyond “heat dissipation.” It demonstrates an outstanding art of balance in core mechanical properties:

- Enhanced Stiffness/Abrasion Resistance: The M100 modulus (stress at 100% elongation) increased by approximately 10-16%, which is typically associated with better abrasion resistance and handling stability, functioning as a Filler to Enhance Abrasion Resistance.

- Perfect Strength Retention: Tensile strength (Ts) and tear strength were maintained at over 97% of the reference formula levels, ensuring the fundamental mechanical integrity of the material. This performance qualifies it as a Reinforced Silica for Tire Tread.

- Remarkable Aging Performance: (Insertion prompt: Insert data tables for “Tensile Product Aging Retention rate as high as 97.7%” and “Tear Strength Aging Retention rate of 95.2%” from the PPT here.) After aging, the retention rate of key properties exceeded 95%, proving that its improved heat dissipation effectively slowed the thermo-oxidative aging process, achieving enduring toughness. This is a primary reason it is considered the Best silica for improving TBR tire durability and lifespan.

3.4 Friendliness to Processing and Technology

Experiments show that the lower Mooney viscosity of the RS925 compound means better processing flowability, aiding extrusion and molding efficiency. Although the optimum cure time (TC90) is slightly extended, the very high cure rate index (TC100) indicates overall efficient curing, providing clear direction for process adjustments in production.

Chapter 4: Beyond Tires – The Pure Guardian: RS925 in the Field of Medical Stoppers

Building on the successful application experience of its sister product RS915 in medical butyl rubber stoppers, RS925 holds great potential in this field due to its high purity, chemical inertness, and excellent reinforcement.

4.1 Solving the “Fragmentation” Pain Point: Exceptional Reinforcement and Abrasion Resistance

The application of RS915 has proven that this type of fine silica can significantly improve the abrasion resistance of halogenated butyl stoppers. RS925 inherits this core reinforcing characteristic. Its formed reinforcement network effectively resists shear and puncture from needles, greatly reducing rubber fragments generated during the puncture process, lowering the risk of drug solution contamination from the source, and meeting the strictest pharmacopoeial standards (e.g., USP <788>). This directly addresses the need for Reducing needle coring and fragmentation in vial stoppers.

4.2 Ensuring “Chemical Inertness”: Safety Assurance from High Purity

Medical applications have extremely high requirements for filler purity. The refined production process of RS925 ensures very low levels of heavy metals and ionic impurities. Its stable chemical surface properties significantly reduce the possibility of adsorbing active pharmaceutical ingredients or causing adverse reactions, providing a safer and more reliable packaging solution for sensitive drugs (e.g., biologics, vaccines). Understanding the Silica filler benefits for medical butyl rubber stopper performance is key for manufacturers in this sector.

4.3 Enhancing Comprehensive Performance

While ensuring purity and inertness, RS925 also provides stoppers with:

- Higher Physical Strength: Improves stopper pull-out force, creep resistance, and ensures sealing reliability.

- Better Processability: Good dispersibility leads to more uniform compound mixing and more consistent stopper performance.

Chapter 5: A Broad Horizon – The Multi-Dimensional Application Vision for RS925

The technical characteristics of RS925 determine that its applications are by no means limited to the above two fields. Any rubber product plagued by thermal management issues and pursuing long-lasting durability and high reliability is a potential stage for its application, showcasing its role as a Functional Silica for Rubber Applications:

- High-Performance Transmission Belts: Reduces internal heat generation during high-speed operation, preventing early breakage due to overheating and extending service life.

- High-Temperature Resistant Seals: Used in seals for engines, hydraulic systems, and other high-temperature environments, improving long-term heat aging resistance.

- Dynamic Damping Components: Such as vibration isolators for large equipment or rail transit, reducing dynamic fatigue heat generation and enhancing durability.

- Specialty Industrial Rolls: Maintains dimensional stability and hardness stability of rolls in continuous heat-generating operations like high-speed printing and papermaking. These diverse uses highlight its nature as a Specialty Silica for Polymer Compounds.

Chapter 6: Comprehensive Advantages – Four Reasons to Choose RS925

- Efficiency Revolution, Targeting the Core: Innovatively combines efficient heat dissipation with powerful reinforcement, solving the fundamental problem of thermal aging in rubber products from a physical mechanism standpoint, rather than being a compromise solution. This makes it a superior Thermally Conductive Silica for Tires and a Cost-effective alternative to carbon black for rubber reinforcement, especially as a Non-Black Filler for Rubber Reinforcement.

- Substantial Data, Balanced Performance: Experimental data comprehensively confirms its advantages in reducing heat buildup, maintaining strength, optimizing dynamic properties, and improving aging resistance, with no shortcomings in key indicators. Engineers looking for a Technical data sheet for thermally conductive reinforced silica will find the data compelling.

- Exceptional Quality, Wide Application: High purity and chemical inertness allow it to span from harsh industrial environments to pristine medical fields, meeting the top standards of different industries.

- Co-creating the Future, Technology Empowerment: The SaneZen Group not only provides high-performance materials but also offers full-chain technical support from formulation development and process optimization to application testing, working with customers to overcome technical challenges and transform material potential into product competitiveness. We aim to be your Partner for developing next generation tire compounds and your High performance silica supplier for rubber industry.

Conclusion

Today, as rubber materials science advances towards higher performance, longer life, and greater sustainability, RS925 Thermally Conductive Fine Silica represents an innovative approach: by endowing the filler with the ability to actively manage the micro-environment (heat), it macroscopically enhances product reliability and durability. It is not only a powerful tool to address current market pain points but also a key to unlocking the design of the next generation of high-performance rubber products. For those seeking a China manufacturer of functional silica for tires, SaneZen stands ready.

The SaneZen Group, driving a sustainable future with technology, looks forward to collaborating with you to explore the infinite possibilities brought by RS925 and bring safer, more durable, and more efficient products to the world.