The rubber industry stands at a critical juncture for transformation, impacted by both global competition and the sustainable development wave. The inherent trade-offs between performance, cost, environmental compliance, and processability in traditional filler systems have become a major bottleneck limiting industry innovation. SaneZen Group, a solution provider deeply rooted in rubber materials science, has leveraged its profound market insights and continuous R&D investment to successfully launch the revolutionary GreenThinking® PF Series Nano Reinforcement Fillers, a premier line of high dispersion nanofiller for rubber. This white paper systematically articulates the cutting-edge nanotechnology behind the PF Series, exemplified by its flagship model PF87, the core industry challenges it addresses, the differentiated value it creates, and its broad application prospects. We are convinced that the PF Series is not merely a new material, but a key engine driving rubber products toward a high-performance, green, and cost-effective future.

Chapter One: Industry Status and Core Challenges — Why Do We Need a Paradigm Shift?

The rubber industry is the foundation of modern manufacturing, applied extensively across critical sectors such as transportation, energy, construction, and healthcare. However, as end-market demands for product performance intensify and global environmental regulations (e.g., REACH, EPA standards) tighten, traditional filler systems are showing limitations, exposing five major core challenges:

1.1 Performance Ceiling and Functional Singularity

- Carbon Black: While offering excellent reinforcement, its dark color restricts use in light-colored or colored products. Furthermore, its manufacturing process and certain grades may raise concerns regarding Polycyclic Aromatic Hydrocarbons (PAHs), leading to environmental pressures. The search for a high-performance rubber Nano filler alternative carbon black is ongoing.

- Precipitated Silica: A key material for “green tires” due to its significant reduction in rolling resistance. However, its high surface energy leads to severe agglomeration, necessitating expensive silane coupling agents for proper dispersion. It also results in high compounding viscosity and high mixing energy consumption, creating a clear need for a cost effective silica replacement filler.

- Mineral Fillers (e.g., Calcium Carbonate, Kaolin, Talc): They are low-cost and widely available, but generally suffer from limited reinforcement (low reinforcement factor), rapid hardness increase, high dynamic heat buildup, and poor dispersion in the rubber matrix, making them unsuitable for high-stress, long-life applications.

1.2 Lack of Critical Performance: The Air Permeability Challenge

For products like tire innerliners, inner tubes, high-pressure hoses, and seals, low gas permeability is a core metric determining service life and safety. Currently, only a limited number of materials can provide excellent air impermeability, but at a high cost. The long-standing, urgent need of the industry is to find a novel filler that balances high reinforcement with high gas barrier property, effectively creating a low permeability tire inner liner material. The goal of enhancing air impermeability in tire inner liner drives significant R&D efforts.

1.3 Compromise on Processing Characteristics

The introduction of many fillers can negatively impact processing: they shorten scorch time (T10), increasing processing safety risks; they raise Mooney viscosity, leading to compounding difficulty, increased extrusion pressure, and rough product surfaces; and they affect flowability, making it difficult to fill complex molds. These factors directly cause a drop in production efficiency and yield, highlighting the critical importance of improving processability of highly filled rubber compounds.

1.4 Persistent Escalation of Cost Pressure

The volatile prices of major raw materials, coupled with the high cost of high-quality functional additives, continuously compress manufacturers’ profit margins. The practical task for every company is how to optimize formulation costs while maintaining or even improving performance, making the promise of cost reduction through high loading rubber fillers highly attractive.

1.5 Rigorous Requirements for Green and Sustainable Development

Driven by “Dual Carbon” goals, the entire manufacturing supply chain is transitioning toward green practices. Rubber products not only require environmental friendliness in the final product, but their production process and raw material sources are also increasingly scrutinized.

Facing these intertwined challenges, simple material substitution or minor formulation adjustments are insufficient. The industry calls for a paradigm-level material innovation.

Chapter Two: GreenThinking® PF Series: Breakthrough Solution in Nanostructure Design

SaneZen Group’s R&D team began with the most fundamental unit of material—the microstructure—proposing the design concept of “Structure Determines Function”. The GreenThinking® PF Series is not a simple grinding of traditional minerals, but a new generation of functional filler created through precise raw material selection, advanced nano-processing, and customized surface activation technology, resulting in unique micro-morphology and surface characteristics.

2.1 Core Technological Innovations

- Nanoplatelet Structure Design: The PF Series, especially PF87, has regular platelet or layered structures with an average thickness in the nanometer scale (D50 ≈ 153nm). This structure is akin to building countless tiny “nanomazes” within the rubber matrix.

- Reinforcement Mechanism: Platelet particles possess a large aspect ratio. When stressed, they can more effectively bear and transfer loads and inhibit crack propagation, providing reinforcement efficiency and tear strength far superior to spherical or blocky particles, establishing it as a superior rubber reinforcement filler.

- Barrier Mechanism: When these nanoplatelets are aligned or randomly stacked within the matrix, they significantly prolong the diffusion path of gas molecules (Tortuosity Effect), thereby creating an exceptional high gas barrier rubber filler and substantially reducing the gas permeability rate.

- Controllable Surface Energy and Interface Optimization: Exclusive surface treatment technology is used to finely tune the surface chemistry of the nanoparticles.

- This reduces the van der Waals forces between particles, effectively preventing nanoparticle agglomeration, and ensuring primary-level dispersion in rubber, a key trait of a true high dispersion nanofiller for rubber.

- It enhances interfacial interaction between the particles and polymer chains, improving stress transfer efficiency.

- High Purity and Batch Consistency: High-whiteness composite mineral raw materials from specific deposits are selected. Strict quality control ensures stable chemical composition, extremely low impurity content, and a bright white color.

2.2 PF Series Typical Product Matrix and Positioning

SaneZen Group offers a complete PF Series product line to meet the nuanced needs of different applications:PF87: Flagship All-Rounder. It achieves the optimal balance between reinforcement, air impermeability, processability, and cost, making it a truly cost effective filler for rubber. It is the ideal choice for replacing N550 carbon black, serving as a cost effective silica replacement filler, and is widely used in tire innerliners, high-end hoses, and seals.

- PF91/PF93: High-Reinforcement Type. Exhibits higher modulus and hardness in sulfur vulcanization systems, suitable for products requiring extremely high stiffness and deformation resistance.

- PF81: High-Flowability Type. Specifically optimized for processing dispersion, featuring lower Mooney viscosity, ideal for improving processability of highly filled rubber compounds.

PF94/PF95: Specialty Reserve Type. Developed for specific performance demands, offering customization space for client solutions as part of our customized specialty rubber chemical development services.

Chapter Three: Quantified Value Proposition — How PF87 Systematically Solves Industry Pain Points

This chapter uses PF87 as an example, combined with detailed data, to specifically demonstrate its transformative value, including a direct filler performance comparison vs N550 carbon black.

3.1 Performance Leap: Reinforcement and Functional Performance Comparable to Premium Fillers

- Static Mechanical Properties: In an EPDM sulfur vulcanization system (130 phr loading), PF87 can achieve a vulcanizate tensile strength of 15.87 MPa, elongation at break remaining at 667%, and 100% modulus of 2.55 MPa. Its comprehensive mechanical performance is comparable to N550 carbon black and far superior to commercial ordinary mineral fillers, proving its efficacy as a nano reinforcement filler for EPDM rubber.

- Exceptional Air Impermeability: Empirical data shows that in a tire inner liner formulation, a compound containing 50 phr of PF87 can improve the gas permeability coefficient by over 26% compared to a traditional calcium carbonate-filled formulation, solidifying its role as the premier low permeability tire inner liner material.

3.2 Processing Empowerment: From “Hard to Handle” to “Smooth and Fluid”

- User-Friendly Processing Window: PF87 effectively extends the scorch time (TS₂). This provides a wider safe operating range, reducing the risk of scorch-related waste.

- Reduced Processing Viscosity: Its unique surface treatment keeps its Mooney viscosity (ML) typically lower than many highly-filled formulations. This translates to lower mixing energy consumption, faster filler incorporation, and a smoother extruded surface.

3.3 Cost Restructuring: The High-Filling Economic Marvel

One of PF87’s most compelling advantages is its extremely high cost-effectiveness, enabling cost reduction through high loading rubber fillers.

- Direct Material Cost Savings: By partially or fully replacing more expensive carbon black or silica, the cost per ton of mixed rubber can be significantly reduced.

Chapter Four: Comparative Advantage — Why Does the PF Series Stand Out?

To clearly present the differentiated value of the PF Series, we systemically compare it with mainstream fillers:

| Characteristic Dimension | Traditional Carbon Black (e.g., N550) | Precipitated Silica | Light Calcium Carbonate | Ordinary Kaolin | GreenThinking® PF87 |

| Reinforcement Effect | Excellent | Good (requires coupling agent) | Poor | General | Excellent, close to N550 |

| Air Impermeability | General | Good | Poor | General | Excellent |

| Color | Black, limited to dark products | White | White | White/Light Color | High Whiteness, suitable for all colors |

| Processability | Fair, higher heat generation | Poor (high viscosity, requires coupling agent) | Good | General, easily absorbs moisture | Excellent (low viscosity, easy dispersion) |

| Environmental Friendliness | Some grades contain PAHs | Good | Good | Good | Excellent (non-toxic and harmless) |

| Cost Index | High | High (includes coupling agent cost) | Low | Low | Medium, but extremely high overall cost-effectiveness |

| Core Value | High Reinforcement | Low Rolling Resistance, Green Tire | Low Cost, Volume Addition | Low Cost, Insulation | High Performance + High Air Impermeability + Green + Excellent Processing + High Cost-Effectiveness |

Furthermore, compared to similar “functional sheet silicate” products launched by a few international chemical giants, the PF Series meets or surpasses key performance parameters. Simultaneously, thanks to local production and supply chain advantages, it offers more competitive pricing and more agile technical service response.

Chapter Five: Full View of Application Scenarios – Empowering Upgrades Across Industries

The versatile properties of the PF Series allow it to penetrate numerous application fields for rubber and its composite materials:

- 5.1 Tire Industry

- Air Barrier Layer/Inner liner: The preferred filler for tire inner liners, providing exceptional gas barrier properties while maintaining processability. It is a key material for manufacturing high-performance radial tires and run-flat tires.

- Sidewalls: Excellent flex fatigue resistance and aging resistance enhance sidewall durability.

Other Components: High loading allows use in body ply compounds and wire coating compounds, reducing cost while maintaining performance.

- 5.2 Hoses and Tubing

- Hydraulic Hoses: PF87 serves as a high performance functional filler for hydraulic hoses, delivering high reinforcement, high-pressure resistance, and excellent air impermeability, making it ideal for demanding applications in engineering machinery, aerospace, and other fields.

- Automotive Fuel Hoses: Outstanding fuel permeation resistance and aging resistance.

- Air Conditioning Hoses: Good refrigerant barrier properties.

- Industrial Transfer Hoses: Wear and corrosion resistance, extending service life.

- Food-Grade/Medical Hoses: Meets relevant certification requirements based on its eco-friendly and non-toxic properties.

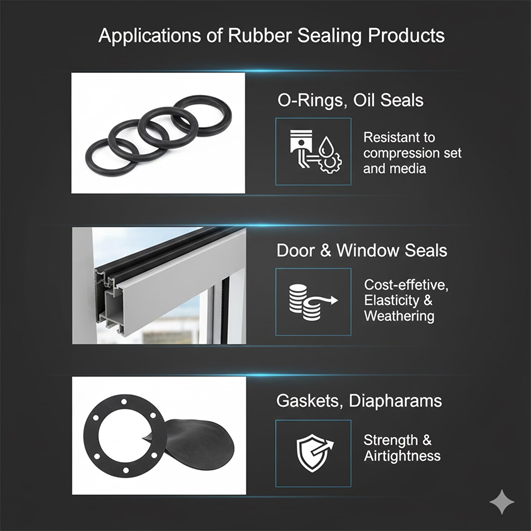

- 5.3 Sealing Products

- O-rings, Oil Seals: Good compression set and media resistance, extending sealing life.

- Door and Window Weatherstripping: High loading reduces cost, while maintaining good elasticity and weather resistance.

- Gaskets, Diaphragms: Provides necessary strength and air impermeability.

- 5.4 Shock Absorption and Power Transmission Components

- Engine Mounts, Bushings: Optimal modulus and damping characteristics.

- Transmission Belts: High reinforcement and low heat generation, enhancing transmission efficiency and durability.

- 5.5 Electric Wires and Cables

- CPE, EPDM Insulation and Sheathing: Imparts good flame retardancy, electrical insulation, and mechanical strength to the material.

- 5.6 Other Fields

- Footwear Materials: High filling reduces density while maintaining softness and abrasion resistance.

- Rubber Flooring, Running Tracks: Abrasion resistance, suitable for colored products.

- Plastics Modification: As a functional filler, it improves the stiffness, dimensional stability, and barrier properties of engineering plastics like PP and PA.

Chapter Six: SaneZen Group’s Added Value – More Than Just Products

Choosing SaneZen Group, a premier rubber filler manufacturer and supplier in China, means gaining a long-term, reliable, technology-centric strategic partner.Deep Technical Accumulation: We possess a team of material science experts and application engineers who understand not just the product, but also rubber processing technology and end-use applications.

- Complete Solution Capability: We provide end-to-end technical support from sample testing, joint formulation development, process optimization guidance, to mass production stability tracking.

- Customized Development Services: We offer customized specialty rubber chemical development to address specific customer needs and rapidly respond to market changes.

- Stable Quality and Supply: Relying on our own factory and strict quality management system, we ensure absolute batch-to-batch consistency, safeguarding the customer’s supply chain security.

- Fast-Response Local Service: As a domestic Chinese manufacturer, we provide faster logistics, more flexible service models, and in-depth communication.

Conclusion and Outlook

The creation of the GreenThinking® PF Series Nano Reinforcement Filler is SaneZen Group’s answer to the call of the rubber industry. With its unique nanoplatelet structure, it ingeniously reconciles previously conflicting goals: “high performance” with “excellent processability,” “superior functionality” with “cost control,” and “outstanding quality” with “green environmental protection.”

It is more than a filler replacement; it is a revolution in design thinking. It offers rubber engineers unprecedented freedom in formulation design and opens a new door for product manufacturers to simultaneously access high-end markets and cost advantages.

We sincerely invite all industry colleagues to explore the potential application of the PF Series in your specific products. Let us join hands, using material innovation as the fulcrum, to collectively drive the Chinese and global rubber industry toward a more efficient, greener, and more competitive future.

To request samples and technical materials, start your material upgrade journey:SaneZen Group Official Website: www.sanezenrubber.com

Business Inquiry Email: yorichen@sanezen.com