Introduction: The Tire Industry’s Performance Triangle Challenge

The tire industry has long grappled with a classic “Magic Triangle” dilemma: the inherent trade-off between abrasion resistance, rolling resistance, and wet grip. Enhancing one property often comes at the expense of another. Meanwhile, the explosive growth of the electric vehicle market and global carbon neutrality goals are demanding more from tires: lower rolling resistance for extended range, superior load-bearing capacity and durability for safety, and better thermal management to handle high thermal loads from instant torque. Traditional filler systems like carbon black and silica are approaching their performance limits. The industry urgently needs a revolutionary material to break through this bottleneck and provide a brand new solution for next-generation high-performance tires. This is where advanced Tire Technology incorporating innovative nanomaterials like Carbon Nanotubes makes a transformative impact, particularly in the development of Green Tires.

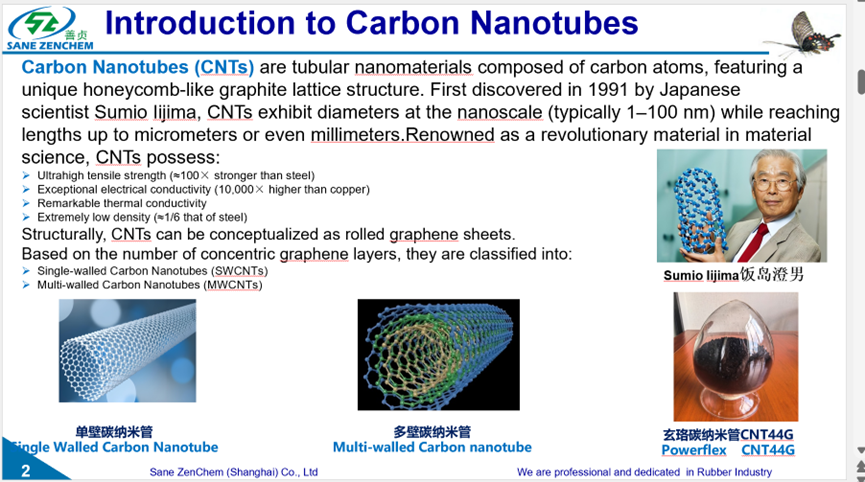

Carbon Nanotubes: The Answer from Materials Science

Since their discovery in 1991, Carbon Nanotubes (CNTs) have astonished the scientific community with their unparalleled properties. This tubular nanomaterial, formed by rolling sheets of graphene, boasts a strength 100 times that of steel, electrical and Thermal Conductivity far exceeding copper, and an extremely low density. However, translating this laboratory marvel into an industrial product hinges on overcoming the biggest challenge: achieving high dispersion within the polymer matrix—agglomerated CNTs not only fail to deliver benefits but can become failure points.

SaneZen Group’s subsidiary, Shanghai Powerflex New Material Co., Ltd., a leading Carbon Nanotube tyre industry Manufacturers China and Carbon Nanotube tyre industry Suppliers China, leveraging its profound expertise in the rubber industry, has successfully overcome this challenge with the introduction of GreenThinking® CNT44G highly dispersed multi-wall carbon nanotubes. This vertically aligned carbon nanotube material is specifically engineered for tire applications. Its unique surface treatment and dispersion technology ensure CNT44G is uniformly distributed at the nanoscale within the rubber matrix, fully translating its exceptional intrinsic properties into the final product. For those seeking tailored solutions, we offer Customized Carbon Nanotube tyre industry products to meet specific performance requirements.

How CNT44G Addresses Core Tire Pain Points

Ultimate Reinforcement, Unbreakable: A Leap in

1.Mechanical Properties

CNT44G possesses ultra-high tensile strength and Young’s modulus. When uniformly dispersed in rubber, it forms a powerful interfacial bond and a three-dimensional network structure, akin to embedding invisible “nano-rebar” throughout the tire. Test data shows that adding CNT44G significantly increases tear strength by 28.1%. This translates to enhanced resistance against curb impacts, cuts from sharp objects, and dramatically improved anti-puncture and anti-blowout capabilities, providing fundamental material assurance for driving safety and significantly improving Abrasion Resistance.

Base formulation of CNT

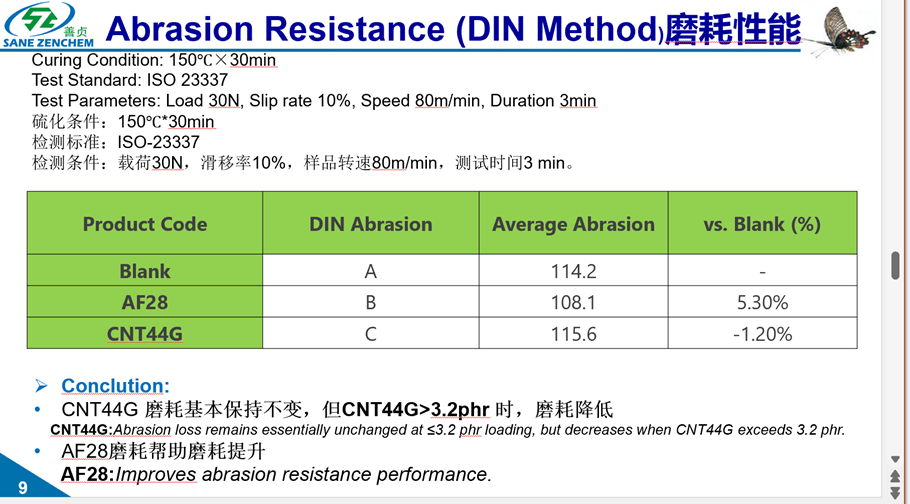

2.Unwearable, The Mileage King: Exceptional Abrasion Resistance

Tire wear is essentially the microscopic loss of rubber material under repeated stress from the road. The nano-reinforcement effect of CNT44G effectively reduces the initiation and propagation of micro-cracks within the tread compound, making the rubber tougher. Test results (ISO 23337) indicate that at optimized loadings, CNT44G effectively reduces abrasion loss. For long-haul commercial vehicle tires and durability-seeking passenger car tires, this directly equates to longer service life and lower total cost of ownership, addressing key concerns for Carbon Nanotube tyre industry Suppliers China and manufacturers alike.

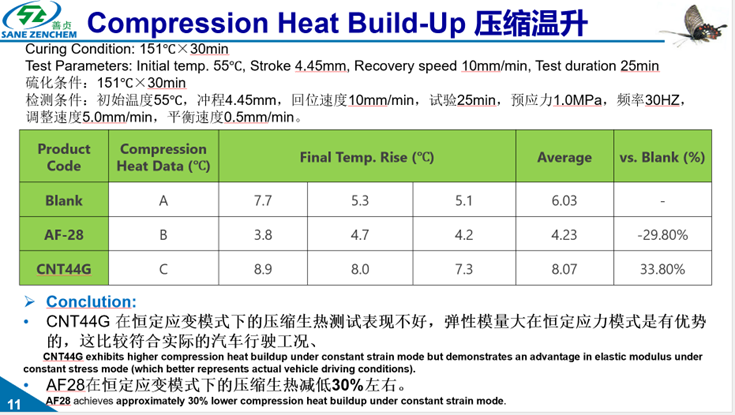

3.The Thermal Master, Cool Running: Thermal Conductivity & Heat Buildup Control

Internal heat generation from hysteresis during driving is a primary cause of performance degradation and aging. The ultra-high Thermal Conductivity of CNT44G creates efficient heat pathways, rapidly drawing heat away from local hot spots and distributing it evenly, preventing thermal degradation and reducing overall Heat Buildup. Thermal conductivity tests confirm a 10.5% improvement in thermal conductivity after adding CNT44G. This not only helps maintain tire performance stability under high-speed and heavy-load conditions but also fundamentally extends tire life.

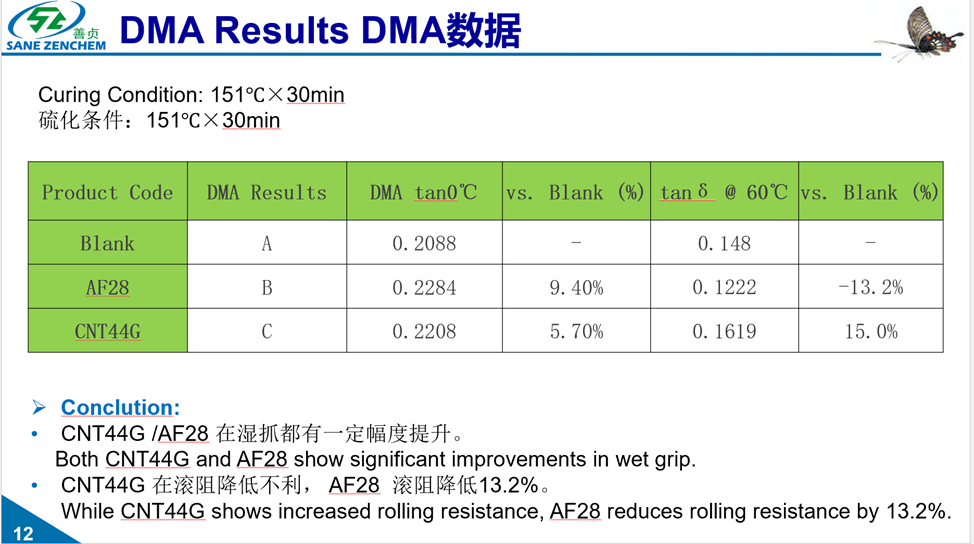

4.Grip and Stability, Assurance in the Wet: Balanced Dynamic Performance

Dynamic Mechanical Analysis (DMA) results demonstrate that the incorporation of CNT44G significantly improves the compound’s Wet Grip performance. This is because the nanotube network influences the viscoelastic response of the rubber at specific frequencies and temperatures, enabling greater energy dissipation (damping) when needed on wet roads, thereby shortening braking distances and enhancing driving safety for High-performance Tires.

Towards a Green Future: Contributing to Lower Rolling Resistance

While CNT44G’s excellent reinforcing properties can slightly increase hysteresis loss, SaneZen Group offers a comprehensive solution. Our AF28 product, used in synergy with CNT44G, achieved an outstanding 13.2% reduction in Rolling Resistance in tests, alongside approximately 30% lower compression heat buildup. This combinatorial strategy provides customers with the flexibility to tailor formulations based on the performance focus of the end product (ultimate durability vs. energy efficiency), perfectly balancing the “performance magic triangle” and supporting the development of Green Tires.

Easy Application, Empowering Industrial Upgrade

CNT44G is designed for convenience in industrial production. It is recommended for addition during the primary (first) mixing stage, with a suggested dosage range of 3-6 phr. Its excellent process compatibility allows tire manufacturers to adopt this cutting-edge material without major modifications to existing production lines, enabling rapid product iteration and upgrade. As experienced Carbon Nanotube tyre industry Manufacturers China, we ensure our products integrate seamlessly into existing manufacturing processes.

Conclusion: Partner with SaneZen to Co-Create the Future

SaneZen Group’s GreenThinking® CNT44G is more than a product; it is the embodiment of our commitment to “Low-Carbon Technology: Pioneering a Sustainable Future.” It represents a quantum leap in tire material technology, offering a practical path to resolving the contradictions between performance, safety, and sustainability. As a trusted Carbon Nanotube tyre industry Suppliers China, we look forward to partnering with leading global tire manufacturers to transform the potential of this nanotechnology into the tangible experience of safer, longer-lasting, and more efficient travel for every vehicle on the road, jointly driving the tire industry toward a more excellent and greener new era. We invite potential partners to explore our Customized Carbon Nanotube tyre industry solutions for their specific application needs.