Introduction: The Role and Challenges of Sealing Materials in Industrial Systems

In modern industrial systems, sealing components are critical elements that ensure the safe and reliable operation of various equipment and systems. Especially in high-end fields such as automotive, aerospace, petrochemical, and military equipment, sealing materials must not only fulfill basic leak-proof functions but also maintain performance stability under harsh conditions like extreme temperatures, chemical corrosion, and long-term compression. Traditional organic silicone rubber and common synthetic rubber often prove inadequate in these environments, suffering from hardening, swelling, permanent deformation, and other issues, which can lead to system failure or even safety incidents in severe cases.

This article delves into the scientific characteristics of fluorosilicone rubber materials and systematically analyzes their technical advantages and engineering application value in addressing industry pain points, incorporating SaneZen Group’s Sanesil FS2200U and FS8200U series products. As a leading fluorosilicone rubber compound supplier China, we are committed to providing global customers with excellent solutions.

1. Core Technical Bottlenecks Faced by Industry Sealing Materials

1.1 Material Degradation Mechanisms in High-Temperature Environments

Ordinary silicone rubber, when used continuously above 150°C, is prone to oxidative scission and thermal degradation of molecular chains, leading to decreased tensile strength, increased hardness, and loss of elasticity. Studies show that traditional methyl vinyl silicone rubber retains less than 50% of its tensile strength after 500 hours of continuous operation at 200°C. Therefore, developing a fluorosilicone rubber with good heat stability up to 230°C has become an urgent industry need.

1.2 Mechanisms of Oil and Solvent Penetration

Non-polar mineral oils and polar chemical solvents penetrate rubber materials primarily through the following pathways:

- Swelling Effect: Small oil molecules infiltrate the rubber cross-linked network, increasing intermolecular distance and causing volume expansion.

- Extraction Effect: Oils dissolve plasticizers and low-molecular-weight components in the rubber, leading to material hardening.

- Chemical Attack: Certain additives (e.g., extreme pressure agents, antioxidants) react chemically with the rubber.

The market urgently needs materials that combine fluoro silicone rubber with excellent solvent resistance and outstanding chemical resistant rubber compound properties to meet these challenges.

1.3 The Physical Nature of Compression Set

Compression Set is a key indicator for measuring a sealing material’s recovery capability. Its causes include:

- Irreversible slippage and rearrangement of molecular chains.

- Structural damage to the cross-linked network.

- Interface failure between filler and matrix.

Therefore, fluorosilicone rubber with low compression set, especially low compression set fluorosilicone for O rings and gaskets, is crucial for ensuring long-term sealing reliability.

1.4 Limitations in Process Adaptability

High-fluorine-content rubber typically has a narrow processing window, presenting technical challenges such as rough extrusion surfaces, insufficient mold flow, and difficult-to-control cure rates. This highlights the necessity of developing extrusion grade fluorosilicone rubber with excellent processing properties and materials suitable for diverse fluorosilicone rubber extrusion and molding applications.

2. The Material Science Foundation and Technological Breakthroughs of Fluorosilicone Rubber

2.1 Molecular Structure Design and Performance Correlation

Fluorosilicone rubber (FVMQ) is a special polymer created by introducing fluoroalkyl groups (typically trifluoropropyl) onto the polysiloxane backbone. This structural innovation brings the following characteristics:

Chemical Structure Advantage:

text

Traditional Silicone Rubber: -Si-O- backbone + methyl side groups

Fluorosilicone Rubber: -Si-O- backbone + trifluoropropyl side groups

Performance Enhancement Mechanism:

- Strong Electronegativity of Fluorine Atoms: Creates a low surface energy surface that resists wetting by oils and solvents, contributing to the properties of high resilience silicone material and fuel resistant sealing material.

- High Bond Energy of C-F Bonds (~485 kJ/mol): Provides excellent thermal stability and chemical inertness.

- Moderate Rigidity of Molecular Chains: Reduces swelling tendency while maintaining elasticity, key to achieving fluorosilicone rubber oil resistance and low compression set.

2.2 Technological Innovation Points of the Sanesil FS2200U/FS8200U Series

2.2.1 Formulation System Optimization

- Selection of Special Fluorosilicone compound : Uses high molecular weight, narrowly distributed raw gum to ensure fundamental performance.

- Reinforcement System Innovation: Employs surface-modified fumed silica to enhance the filler-matrix interface bonding strength, increasing material strength.

- Cross-linking Network Design: Optimizes the peroxide curing system to form a uniform and dense three-dimensional network, thereby developing high-performance fluorosilicone rubber compound.

2.2.2 Key Performance Data Comparative Analysis

Table 1: Full Hardness Range Performance Parameters of FS2200U Series

| Property | FS2230U | FS2240U | FS2250U | FS2260U | FS2270U | FS2280U | Test Standard |

| Hardness (Shore A) | 30±2 | 39±2 | 50±2 | 59±2 | 71±2 | 79±2 | ASTM D2240 |

| Tensile Strength (MPa) | 9.7 | 10.4 | 10.4 | 10.1 | 10.0 | 9.1 | ASTM D412 |

| Elongation (%) | 498 | 410 | 358 | 295 | 254 | 200 | ASTM D412 |

| Compression Set (%) (177℃×22h) | 7.5 | 6.2 | 6.8 | 6.9 | 6.9 | 7.4 | ASTM D395 Method A |

Table 2: Fluid Resistance Comparison (Taking FS2250U as an Example)

| Test Medium | Condition | Hardness Change (pts) | Tensile Strength Change (%) | Volume Change (%) | Performance Rating |

| Fuel C | 23℃×70h | -10 | -40 | +18 | Excellent |

| 903# Oil | 23℃×70h | -6 | -25 | +3.0 | Very Good |

| ASTM #3 Oil | 150℃×70h | -12 | -35 | +8 | Good |

| Methanol | 23℃×168h | -5 | -15 | +2 | Very Good |

2.2.3 Process Performance Breakthroughs

- FS2200U Series: Optimized for molding and calendering processes, with good flow and excellent mold release properties, making it an ideal molding material.

- FS8200U Series: Specially designed for extrusion processes, it is a high-performance extrusion grade fluorosilicone rubber with die swell <15% and surface roughness Ra <1.6μm, perfectly meeting the production needs of complex cross-section seals.

3. Engineering Application Scenarios and Solutions

3.1 Automotive Industry: Meeting the Dual Requirements of New Energy and Traditional Powertrains

Electric Vehicle Applications:

- Battery cooling system seals: Resistant to glycol-based coolant, long-term operation at 120°C.

- Motor insulation components: Compliant with ISO 6722 Class C temperature class.

Traditional Fuel Vehicle Applications:

- Fluorosilicone rubber for automotive fuel system seals: Fuel line quick connector seals, with fuel permeation resistance <10 g/m²·day (40°C).

- Turbocharger system seals: Resistant to hot air aging, with >80% property retention after 1000 hours at 230°C.

As a professional fluorosilicone rubber suppliers, we provide tailor-made fuel resistant sealing material and solutions for the automotive industry.

3.2 Aerospace: Ensuring Reliability in Extreme Environments

Case Study: Aircraft Fuel System Seals

- Operating conditions: -54℃ to 177℃ cycling, immersion in JP-8 fuel.

- After using FS2260U material:

- Seal life increased from 500 hours to 2000 hours.

- Leakage rate reduced to the order of 10⁻⁶ Pa·m³/s.

- Meets MIL-PRF-25988 standard requirements.

The silicone rubber for aerospace provided by SaneZen is a trusted high performance sealing solutions for aerospace industry. Our materials are an ideal choice for manufacturing O ring material resistant to 230℃ high temperature that meets stringent standards.

3.3 Petrochemical Industry: Multi-Medium Compatibility Solutions

Refining Plant Valve Sealing System:

- Challenge: Simultaneous exposure to hydrocarbons, sour gas, and hot water vapor.

- Solution: Adopt FS2270U custom formulation.

- Resistant to H₂S partial pressure of 0.1MPa (1000ppm).

- Resistant to hot water (150℃) with volume change <5%.

- Stable performance in mixed media of ASTM Oil #1 and #3.

We provide high temperature resistant sealing material for oil and gas industry, especially oil resistant silicone material for hydraulic systems, ensuring equipment safety under bad operating conditions.

3.4 Military Equipment: All-Terrain, All-Weather Adaptability

Field Operation Equipment Seals:

- Temperature range: -60℃ (cold region) to 230℃ (desert equipment surface).

- Resistant to hydraulic oil, grease, diesel, and other media.

- Abrasion resistant to sand and dust, with surface hardness stability of ±3 Shore A.

Our fluorosilicone rubber products meet the stringent requirements of military equipment for wide temperature ranges and resistance to multiple media.

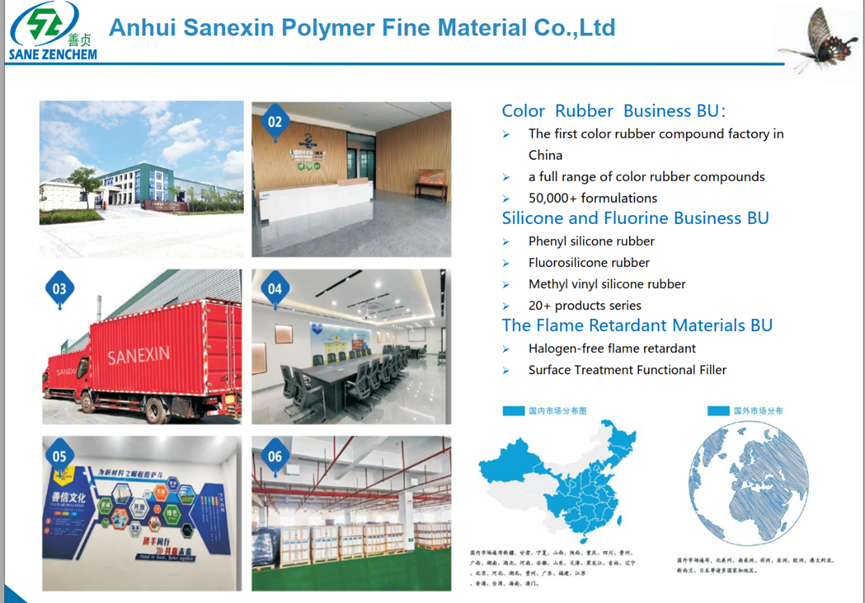

4. SaneZen Group’s Special Silicone Production Base: Full Industrial Chain Capability from Material R&D to Part Manufacturing

4.1 Infrastructure and Manufacturing Platform

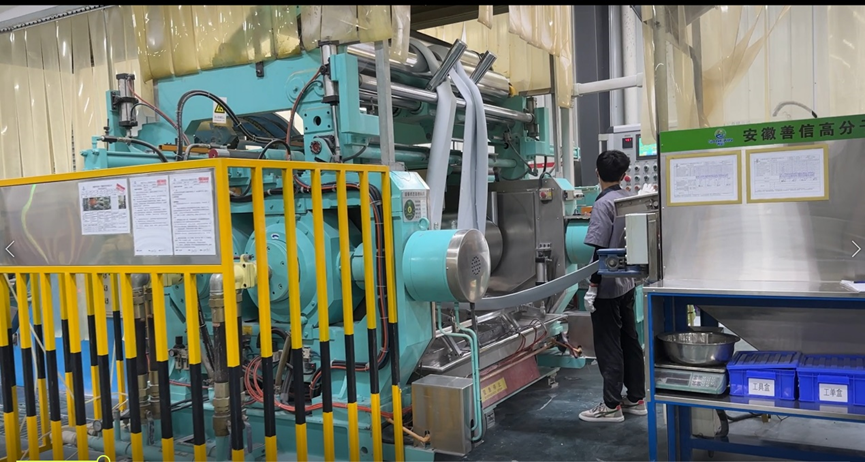

As a fluoro silicone manufacturer China and a China fluorosilicone rubber manufacturer with cleanroom production, we possess:

Nation’s First Full Cleanroom (Class 1000):

- Clean area: 12,000 square meters.

- Temperature and humidity control: 23±2°C, 45±5% RH.

- Microparticle control: ≥0.5μm particle count <1000 per cubic foot, ensuring the ultimate purity and batch consistency of fluorosilicone rubber compound.

Full Range Silicone Production Capability Matrix:

As a comprehensive custom silicone rubber compound factory, we produce not only fluorosilicone rubber but also various special silicones including high-temperature and liquid silicone rubber, meeting customers’ diverse needs.

4.2 R&D and Quality Control System

Four-Level R&D Platform:

- Basic Research Center: Molecular design, polymerization processes.

- Formulation Laboratory: Application-oriented formulation development, capable of providing custom color and hardness fluorosilicone compounds.

- Process Engineering Department: Mass production process optimization.

- Application Testing Center: Simulated operating condition testing and validation.

Whole-Process Quality Control Points:

- Raw material be put in storage: 18-parameter inspection.

- Production process: Online rheology monitoring + per-batch sampling.

- Finished product leave factory: Full property testing (physical, chemical, aging).

- Traceability system: Each product batch traceable to raw material batch and production parameters.

4.3 Customization Service Capability

Rapid Response Development Process:

text

Customer Need → Material Selection (24h) → Formulation Design (72h) → Sample Preparation (1-2 weeks) → Performance Testing (1-2 weeks) → Process Optimization → Mass Production

We are not only fluorosilicone rubber suppliers but also your professional custom fluorosilicone compound supplier, dedicated to providing special custom products like fluoro silicone rubber with excellent solvent resistance.

Success Case: Low-Temperature Resistant Seal Development for an Aerospace Enterprise

- Requirement: Maintain elasticity at -65°C, resistant to RP-1 rocket kerosene.

- Development cycle: 45 days.

- Result: Material Tg < -70°C, volume change in RP-1 < 10%, obtained AS9100 certification.

5. Future Technology Trends and SaneZen’s R&D Layout (New Content)

With the advancement of Industry 4.0 and increasing environmental requirements, future fluorosilicone rubber materials will develop towards higher performance, functionality, and sustainability. SaneZen Group will continue to invest in R&D, focusing on developing new types of fluorosilicone chemical resistant rubber compound with higher strength, longer lifespan, and easier processing. We will deepen material innovation in core areas like automotive fuel system seals and aerospace high performance sealing solutions, consolidating our position as a key global fluoro silicone manufacturer China.

6. Conclusion

Fluorosilicone rubber, as a specialty elastomer material, demonstrates irreplaceable technical advantages in addressing sealing challenges under extreme operating conditions. Through continuous R&D investment, a well-established production system, and in-depth customer collaboration, SaneZen Group not only provides mature product series like FS2200U/FS8200U but also builds full-process solution capabilities from material selection and formulation customization to part manufacturing.

As industrial equipment develops towards higher parameters and more severe environments, unprecedented challenges are posed to sealing materials. SaneZen will continue to uphold the philosophy of “Material Innovation Drives Industrial Progress” and, as your reliable fluorosilicone rubber compound supplier China, work with global partners to advance sealing technology, providing reliable, efficient, and sustainable sealing solutions for various industries.

Technical Consultation and Sample Request:

Welcome to visit our official website for detailed technical information, or contact our application engineering team for in-depth communication:

- Sample Request: Email: yorichen@sanezen.com

- Application Engineering Support: techsupport@sanezen.com

- Business Contact: Email: yorichen@sanezen.com

- Contact Phone: +86 21 6487 9251 (ext. 114) or contact directly via WhatsApp: +86 136-7164-1995

Production Base Visit Appointment:

We welcome customers to visit our production base located in Xuancheng, Anhui, to personally experience the manufacturing capabilities and quality system of our China fluorosilicone rubber manufacturer with cleanroom production. Please schedule via email two weeks in advance.