Introduction: The Dual Challenges of Rubber Performance Decay

In rubber products, especially in the fields of tires and Vibration Damping Rubber Compounds, “dynamic heat generation” and “sulfur reversion” are two core technical bottlenecks leading to product performance decay and shortened service life. Dynamic heat generation not only induces material thermal aging but also directly leads to modulus decrease and accelerated fatigue. Sulfur reversion destroys the cross-linking network structure, causing permanent deterioration of physical properties. How to systematically solve these two major problems without sacrificing rubber strength, elasticity, and processing efficiency is a severe challenge for every rubber technical engineer.

I. In-depth Problem Analysis: Understanding “Heat Generation” and “Reversion” from a Molecular Perspective

1.1 The Root Cause of Dynamic Heat Generation: Interface Slip and Hysteresis Loss

Under periodic dynamic loading, rubber molecular chains and fillers (such as carbon black) are not stably bonded but are in a continuous state of “adsorption-desorption-slip.” This friction at the microscopic level converts valuable mechanical energy into heat energy, known as “hysteresis loss.” Especially in systems based on natural rubber (NR), if carbon black is poorly dispersed, it forms local stress concentration points, drastically intensifying internal friction heat generation (Rubber Compression Heat Build-up). The temperature rise, in turn, accelerates rubber oxidation, further destroying the molecular chain structure, forming a vicious cycle of “heat generation → aging → further heat generation,” which is a core issue in How to Reduce Rubber Dynamic Heat Generation.

1.2 The Essence of Sulfur Reversion: Thermal Degradation of the Cross-linking Network

Under high-temperature use or over-curing conditions after vulcanization, the cross-linking network composed of polysulfide bonds (-Sx-) undergoes thermal cleavage, breaking into monosulfide or disulfide bonds with lower bond energy and shorter chain length. This process leads to a significant decrease in cross-link density, macroscopically manifested as reduced hardness, decreased modulus, and increased permanent set. Natural rubber is particularly sensitive to reversion due to the high saturation of its molecular backbone and lack of unsaturated double bonds for stress rearrangement, severely limiting its application in high-end dynamic products, thus creating a need for effective Rubber Reversion Prevention Method.

II. Systematic Solution: The “Triple Action Mechanism” of the AF2X Series

The GreenThinking® AF27 and AF28 Anti fatigue Agent for NR launched by PowerFlex New Materials (SaneZen Group) are functional additives developed based on molecular design concepts. They address the challenges of heat generation and reversion at the root through a synergistic “Coupling-Modification-Stabilization” triple action mechanism, which is key to Improve Dynamic Properties of Rubber.

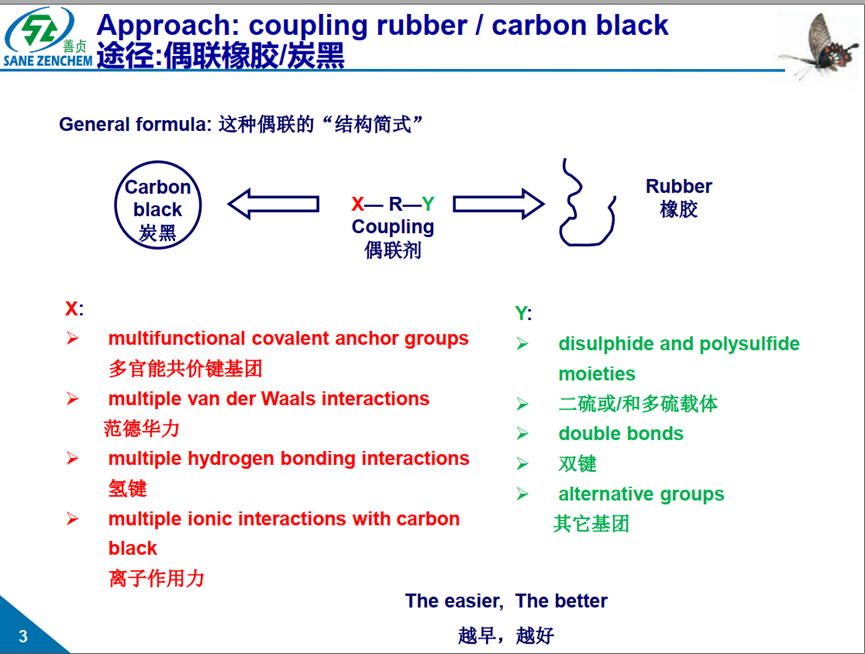

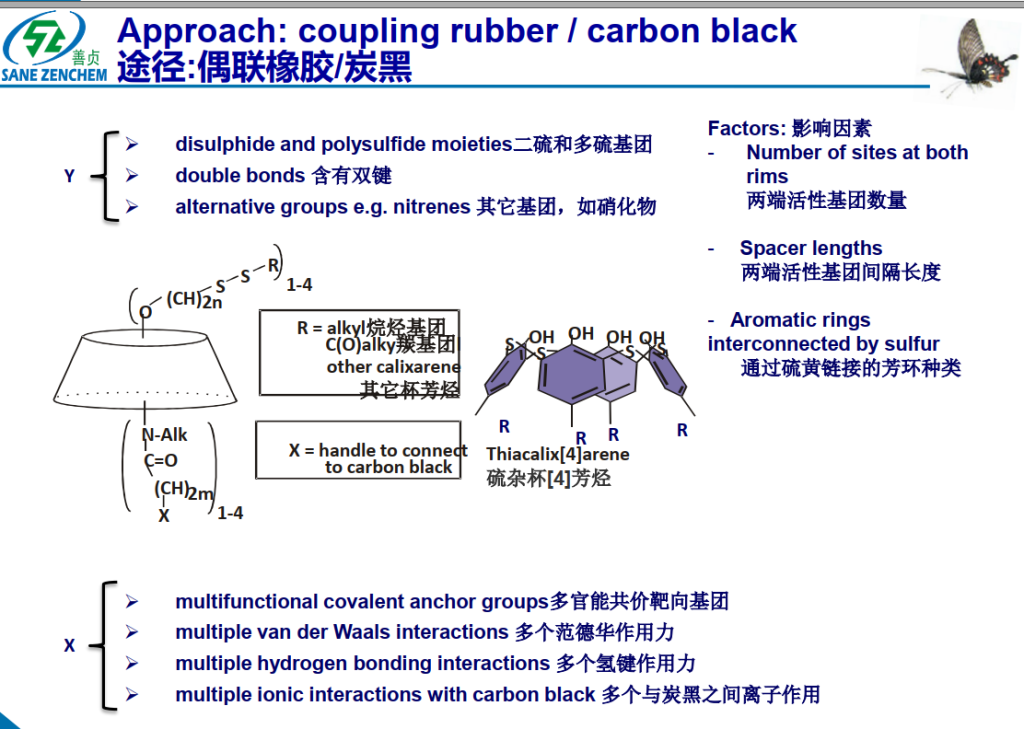

Mechanism One: Coupling Filler and Rubber for Low-Friction Dispersion

One end (X-end) of the AF2X molecular structure contains highly active groups such as hydrazide and hydroxyl groups, which can form covalent bonds or strong hydrogen bonds with carboxyl, phenolic, lactone, and other functional groups on the carbon black surface (acting as a Carbon Black Dispersant); the other end (Y-end) contains polysulfide groups or double bonds that can react with the rubber molecular chains. This unique “bridging” structure establishes a robust “filler-coupler-rubber” three-dimensional interface layer between carbon black and rubber.

• Effect: Greatly improves the dispersion of carbon black (helps Optimize Carbon Black Dispersion in Rubber Formulation), reducing stress concentration caused by filler agglomeration.

• Result: Significantly reduces the sliding resistance of molecular chains on the filler surface, thereby reducing hysteresis loss and dynamic heat generation (a primary Method to Reduce Rubber Compression Heat Build up and addresses How to Reduce Rubber Dynamic Heat Generation) at the source.

Mechanism Two: Capping Rubber Molecular Chains for Enhanced Toughness and Elasticity

AF2X can chemically react with the terminal aldehyde groups or active groups of natural rubber molecular chains, achieving chemical capping and graft modification of the molecular chains (the role of an Anti fatigue Agent for NR).

• Effect: Reduces the number of free chain ends, restricting futile chain segment motion.

• Result: Significantly improves the modulus, hardness, and rebound resilience of the compound without significantly affecting tensile strength, achieving the ideal mechanical state of “strong but not hard, elastic but not soft,” helping to Improve Performance of Rubber Damping Products and Enhance Dynamic Mechanical Properties of Rubber.

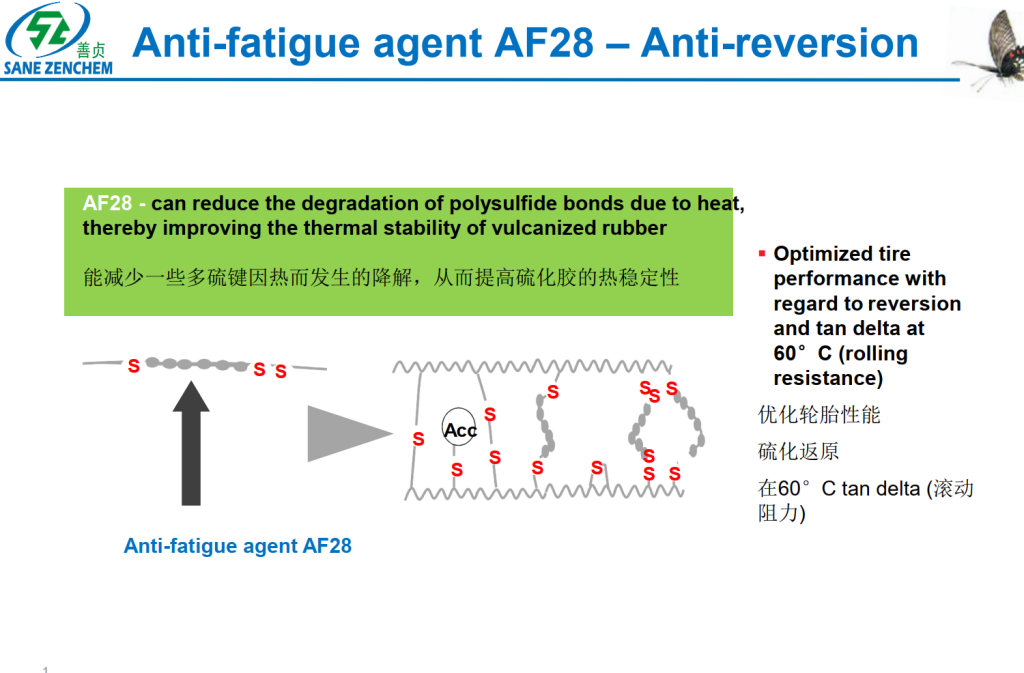

Mechanism Three: Stabilizing the Cross-linking Network, Imparting Anti-Reversion Capability

During the vulcanization process, AF2X can participate in and optimize the formation of the cross-linking network. More importantly, it can inhibit the breakage and rearrangement of polysulfide bonds under high temperature (functioning as an Anti reversion Agent, providing a Rubber Reversion Prevention Method).

• Effect: Enhances the thermal stability of the cross-linking network (a Solution for Improving Rubber Thermal Stability), delaying the network structure destruction caused by thermal degradation.

• Result: Enables the vulcanizate to better maintain its original physical and mechanical properties after high-temperature or long-term use (Technology to Extend Rubber Product Life), greatly extending the service life of the product.

III. Laboratory Validation and Typical Application Effects

The following data are derived from actual test results in the product technical documentation, providing you with reliable performance references.

3.1 Performance Improvement of AF27 in Vibration Damping Products

Adding 1.2 phr AF27 to a standard Vibration Damping Rubber Compound formulation resulted in the following performance comparison:

• Optimized Damping Performance: The dynamic-static stiffness ratio (Kd/Ks) decreased significantly from 1.46 to 1.34 (Dynamic Static Stiffness Ratio Optimization). This means that under the same load, more energy is used for effective damping rather than being converted into harmful heat, greatly optimizing the damping effect.

• Improved Elasticity and Fatigue Resistance: The compound’s rebound resilience was significantly improved, while the reduction in dynamic heat generation directly led to enhanced fatigue resistance, suitable for applications undergoing long-term vibration.

• Enhanced Dimensional Stability: Effectively prevents the “reversion” phenomenon of the vulcanizate after high temperature or prolonged use, ensuring dimensional and performance stability throughout the product’s life cycle.

Application Direction: These characteristics make AF27 an ideal choice for products such as rail transit damping pads, engineering machinery supports, and building isolation bearings, helping to Improve Performance of Rubber Damping Products.

3.2 Comprehensive Benefits of AF28 in Tire Formulations

Adding 1.0 phr AF28 to a standard tread compound formulation yielded the following test results:

| Performance Indicator | Base Formula | Base Formula + AF28 | Key Improvement |

| Curing Efficiency T90 (min) | 10.21 | 7.21 | ~29% increase in curing efficiency, directly improving production efficiency. |

| Rolling Resistance (tan δ @60℃) | 0.098 | 0.080 | Significantly reduced by 18.4% (a key Solution for Tire Rolling Resistance), helping Reduce Rolling Resistance and fuel consumption during tire operation. |

| Rebound Resilience (%) | 43 | 49 | ~14% improvement in elasticity, beneficial for ride comfort and handling response. |

| Tensile Strength Retention after Aging | Baseline | Improved >5% | Delays thermal aging, extends product service life (works to Improve Heat Aging Resistance of Tires). |

Application Direction: AF28 is a powerful technical upgrade tool for manufacturers committed to developing high-performance car tires with low rolling resistance, long-life truck and bus tires, and engineering tires resistant to harsh conditions (a Recommended High performance Tire Additive for such goals).

IV. Why Choose SaneZen AF2X Series?

• Precise Positioning: Specifically designed for natural rubber systems, directly targeting the pain points of NR dynamic heat generation and reversion.

• Product Segmentation: AF27 specializes in vibration damping products, optimizing the dynamic-static stiffness ratio; AF28 focuses on tire applications, powerfully reducing rolling resistance.

• Green and Safe: GreenThinking® series products comply with environmental regulations, supporting sustainable manufacturing.

• Professional Support: SaneZen Group provides full-process professional technical support from formula development and process debugging to performance validation. As a leading Rubber Anti fatigue Agent Manufacturer and Natural Rubber Anti fatigue Agent Supplier, we stand behind our products.

V. Conclusion: From Passive Response to Proactive Design

The advancement of rubber technology is moving from “formula adjustment” relying on empirical formulas to “proactive architecture” based on molecular interface design. The GreenThinking® AF27 and AF28 anti-fatigue agents are outstanding representatives of this concept. Through microscopic molecular coupling and network stabilization, they achieve a systematic improvement in macroscopic properties, providing customers with a reliable technical solution to overcome the challenges of dynamic heat generation and sulfur reversion.

If your products are facing:

• Short service life due to excessive dynamic heat generation?

• Affected end-customer brand reputation due to rapid performance decay?

• Seeking to Reduce Rolling Resistance to enhance market competitiveness?

Welcome to contact the SaneZen team ( website : sanezenrubber.com ) to obtain free samples, detailed technical data sheets (TDS), or customized application proposals. We provide the Solution for Improving Rubber Thermal Stability and the Technology to Extend Rubber Product Life.