Industry Pain Points and Challenges

1. Thermal Degradation and Sulfur Reversion in Rubber

Rubber products, especially those used in high-temperature environments (e.g., tires, conveyor belts, and shock absorbers), face severe thermal degradation and sulfur reversion. For engineers searching for the best rubber anti-reversion agent for tires, this is a critical challenge. During vulcanization, polysulfide bonds break under heat, leading to:

- Loss of crosslinking density

- Reduced mechanical properties (tensile strength, elongation)

- Increased rolling resistance in tires – a key concern for those looking to reduce rolling resistance

- Poor aging resistance

2. Dynamic Fatigue and Performance Loss

Rubber components subjected to repetitive stress (e.g., tire sidewalls, motor mounts) suffer from:

- Dynamic stiffness increase → Harsh ride quality

- Creep deformation → Dimensional instability

- Metal-rubber bonding failure → Premature tire damage (highlighting the need for rubber-to-metal bonding improvement)

3. Compromised Durability in High-Temperature Applications

Conventional rubber formulations struggle with:

- Hot air aging (70°C–100°C) causing hardness spikes and strength loss – a problem solved by high-performance rubber crosslinking solutions

- Compression set issues leading to permanent deformation

Solution: GreenThinking® RT88 – The Ultimate Rubber Stabilizer

1. Stable Crosslinking Structure for Superior Heat Resistance

For manufacturers wondering how to improve rubber thermal stability, GreenThinking® RT88 forms thermodynamically stable carbon-sulfur bonds during vulcanization, combining:

- Mono-sulfide/di-sulfide stability (resists reversion)

- Polysulfide flexibility (maintains dynamic performance)

Data Proof:

- 70°C aging tests show -7.6% elongation loss (vs. -17.4% in blanks).

- 100°C aging reduces tensile strength loss by 9.4% (RT88: -15.5% vs. blank: -24.9%).

2. Anti-Sulfur Reversion Performance

As the best rubber anti-reversion agent for tires, RT88 compensates for broken polysulfide bonds, maintaining crosslinking density under over-vulcanization.

Key Metrics:

- Compression set improvement: 16.09% (RT88) vs. 18.09% (blank).

- Hot air aging resistance: Hardness change reduced to +5 points (vs. +6 in blanks).

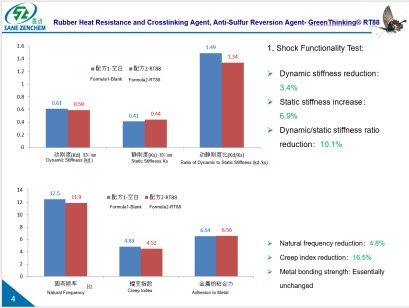

3. Dynamic Performance Enhancement

- 3.4% reduction in dynamic stiffness → Smoother vibration damping.

- 16.5% lower creep index → Better dimensional stability.

Metal bonding strength preserved → Critical for rubber-to-metal bonding improvement.

4. Rolling Resistance Reduction for Tires

RT88’s optimized crosslinking network helps reduce rolling resistance by:

- Lowering hysteresis → Fuel efficiency improvement.

- Extending tire lifespan under high-speed conditions.

Learn more about GreenThinking® RT88’s advanced rubber stabilization technology: https://sanezenrubber.com/wp-content/uploads/2025/07/Data-GreenThinking_-RT88-EN-.pdf

Why Choose GreenThinking® RT88?

| Feature | RT88 Benefit | Competitive Gap |

| Heat Resistance | Stable bonds resist 160°C+ vulcanization | Conventional agents degrade above 140°C |

| Anti-Reversion | 10.1% lower dynamic/static stiffness ratio | Competitors fail under prolonged heat |

| Durability | 24.7% less elongation loss after 100°C aging | Industry average: 35–40% loss |

| Ease of Use | Mixes directly with sulfur/accelerators (0.5–3.0 phr) | No complex pre-treatment needed |

Applications

- Tires: Improves rolling resistance and high-speed durability – ideal for special rubber chemical manufacturers seeking premium additives.

- Shock Absorbers: Reduces dynamic stiffness by 3.4%.

- Industrial Belts: Enhances heat aging resistance by 30% – a key advantage for special rubber chemical suppliers China.

Conclusion

For special rubber chemical manufacturers China and global partners, GreenThinking® RT88 delivers:

✔ Unmatched heat resistance via stable crosslinks.

✔ Anti-reversion properties making it the best rubber anti-reversion agent for tires.

✔ Proven performance in high-performance rubber crosslinking solutions.

Trusted by special rubber chemical suppliers worldwide, RT88 is the ultimate solution for durable, heat-resistant rubber formulations.

As special rubber chemical supplier China we provide wide range of bio based tire additive for customers and committed to create value for customers .

For more tire additive our tire brochure for your reference : https://sanezenrubber.com/wp-content/uploads/2025/07/SaneZen-Brochure-Tyre-EN.pdf