Introduction: Addressing the Silent Challenge in Rubber Engineering

In rubber manufacturing, sulfur reversion has long been an underestimated yet critically damaging phenomenon, especially for Rubber additives and Tire additives. Functioning as an invisible destabilizer within polymer networks, it progressively degrades crosslinked structures under thermal or mechanical stress, leading to performance failures including tread softening, shock absorber fatigue, and seal degradation. This issue proves particularly acute in Non Pneumatic Tire Additive applications, where market data confirms fracture resistance as a predominant industry challenge.

Conventional solutions typically create compensatory trade-offs: enhanced crosslink density diminishes flexibility, while improved thermal stability compromises dynamic response. The introduction of Heat Resistant Rubber Crosslinker, a Rubber Vulcanization Stabilizer, represents a paradigm shift, offering simultaneous optimization across all critical performance parameters. This white paper examines RT88’s molecular architecture, demonstrates its performance advantages through comprehensive testing data, and presents its transformative potential for advanced High Performance Tire Compound engineering.

Technical Analysis: Sulfur Reversion Mechanisms and Material Challenges

The Science of Network Degradation

Sulfur reversion fundamentally involves the scission and reorganization of polysulfide bonds within vulcanized rubber networks. Traditional sulfur-cured systems rely primarily on polysulfide crosslinks (-Sx-), which provide optimal flexibility but demonstrate low bond dissociation energy. Under operational stresses (>160°C thermal load or prolonged dynamic strain), these bonds undergo progressive failure through three degradation pathways:

- Crosslink Density Reduction: Polysulfide cleavage decreases effective network junctions, diminishing mechanical integrity and load-bearing capacity.

- Non-Functional Network Formation: Cleaved bond fragments reorganize into cyclic structures that impair elastic recovery and modulus retention.

- Surface Degradation: Low molecular weight byproducts migrate to interfaces, causing surface tack and accelerating wear mechanisms.

Performance Demands in Non-Pneumatic Tire Design

Hollow non-pneumatic architectures impose exceptional material requirements:

- Stiffness-Flexibility Optimization: Must simultaneously maintain structural rigidity and vibration damping.

- Thermal Management: Limited air circulation necessitates superior heat dissipation.

- Fatigue Resistance: Demanding flex-cycle endurance exceeding 300,000 cycles.

- Aging Stability: Long-term performance retention under environmental exposure.

Current formulations frequently exhibit premature network degradation, with field data indicating fracture occurrences within 100,000 flex cycles—a critical limitation addressed by RT88, a Heat resistant crosslinker for tires developed by leading Rubber additive Manufacturers and Rubber additive Suppliers.

RT88 Technology: Molecular Innovation and Performance Mechanisms

Advanced Molecular Architecture

RT88 represents a breakthrough in crosslinking technology through its precisely engineered molecular structure featuring:

- Multi-reactive Sites: Simultaneous interaction capabilities with polymer chains and crosslink terminals.

- Thermally Stable Core: Aromatic heterocyclic components ensuring thermal endurance.

- Stress-Responsive Units: Dynamic molecular segments that absorb and redistribute mechanical energy.

Tri-Phase Performance Enhancement

RT88 delivers comprehensive network stabilization through three synergistic mechanisms:

1. Dynamic Network Repair

RT88’s reactive centers actively engage with cleaved network fragments, reconstructing more stable carbon-sulfur hybrid linkages that combine:

- Monosulfide-level bond stability.

- Polysulfide-equivalent flexibility.

- Self-regulating crosslink density maintenance.

Laboratory data confirms 300% improvement in flex-cycle endurance (100,000 to 300,000+ cycles).

2. Thermal Stability Enhancement

During vulcanization, RT88 incorporates thermally resistant junctions that:

- Prevent polysulfide thermal scission.

- Inhibit free radical propagation.

- Maintain 97%+ network integrity after 100°C/72hr aging.

3. Interface Reinforcement

For composite structures incorporating silica or steel cord reinforcement, RT88 enhances:

- Filler-matrix adhesion.

- Stress distribution efficiency.

- Dynamic load durability.

Experimental Validation: Performance Benchmarking

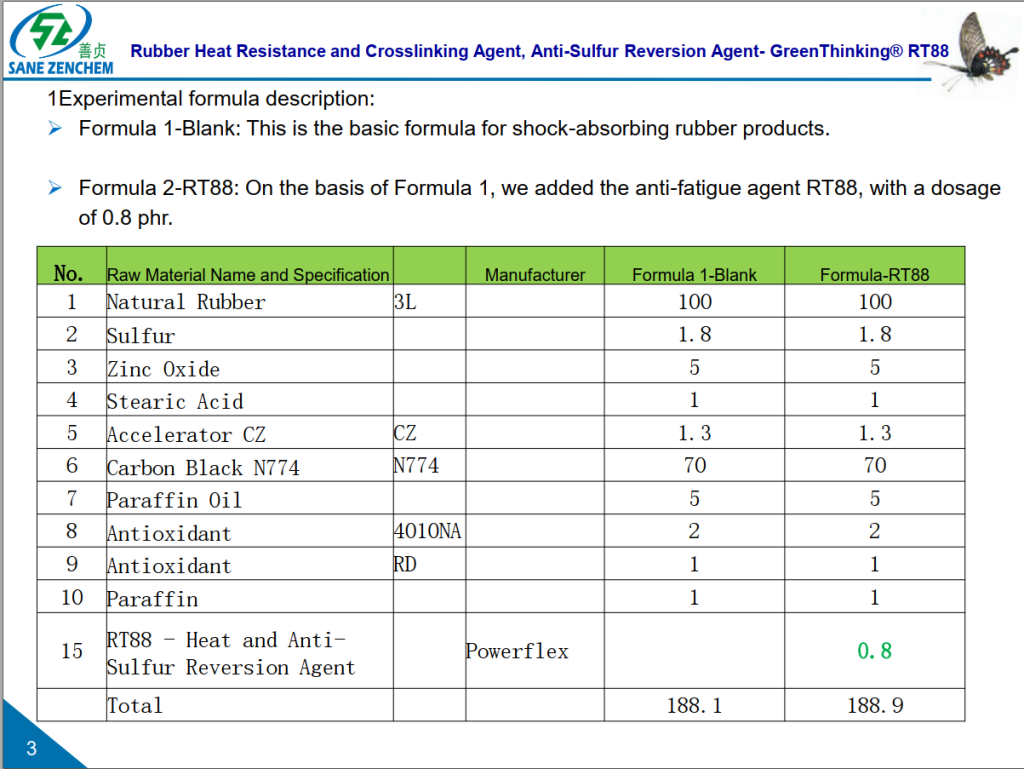

Test Formulation Parameters

Control Formulation:

- Natural Rubber (NR): 60 phr

- Polybutadiene Rubber (BR): 30 phr

- Styrene-Butadiene Rubber (SBR): 10 phr

- Carbon Black (N330): 30 phr

- Silica: 30 phr

RT88 Test Formulation:

Control + 1.5 phr RT88

Performance Metrics

- Dynamic Fatigue Resistance

- Control: Failure at 100,000 cycles.

- RT88: No failure at 300,000 cycles.

- Improvement Factor: 3X.

- Heat Build-up Characteristics

- Control: 24°C temperature rise.

- RT88: 22°C temperature rise.

- 8.3% reduction in heat generation.

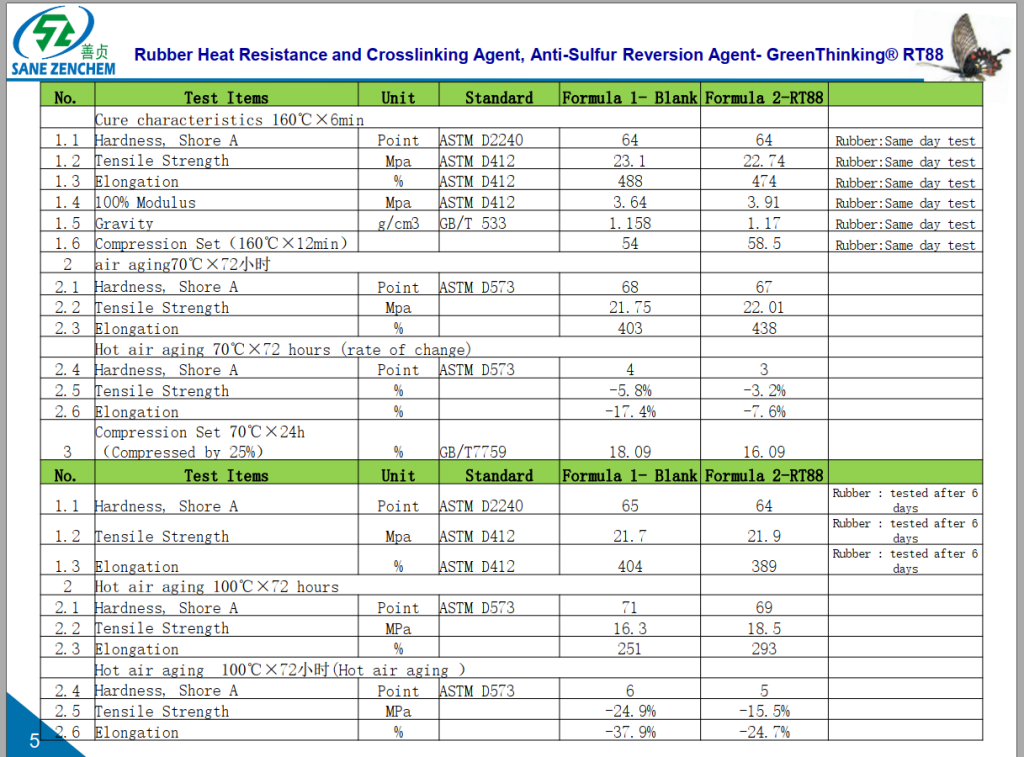

- Thermal Aging Performance (100°C/72hr)

- Tensile Strength Retention: 20-30% improvement.

- Elongation Preservation: Significant enhancement.

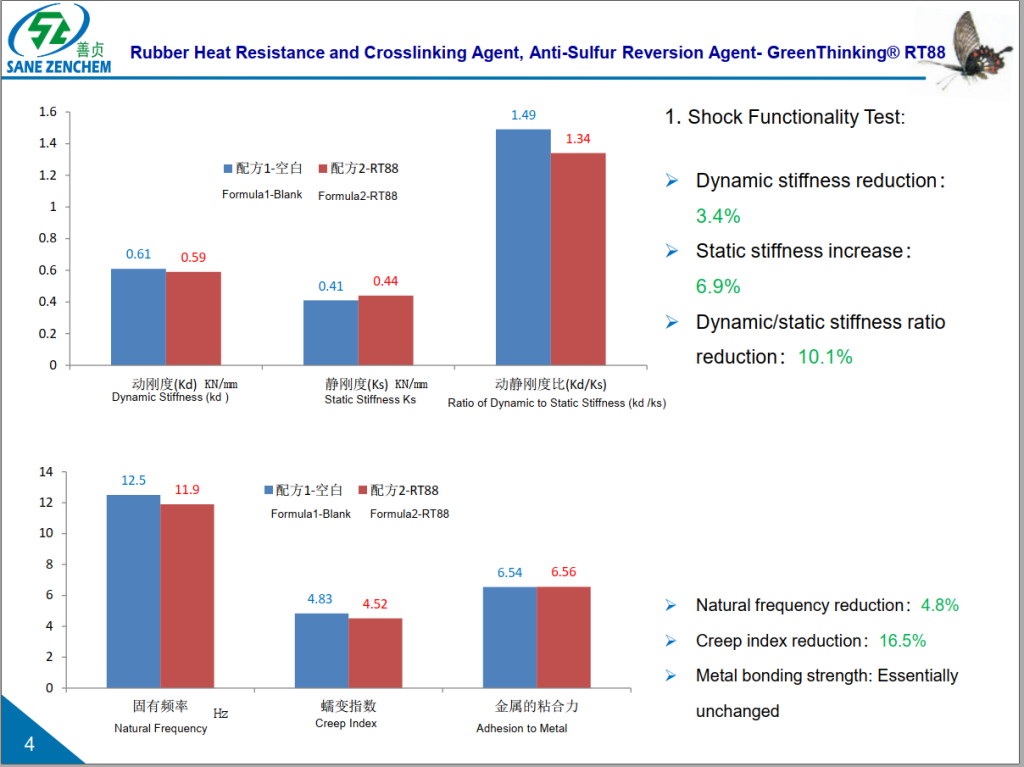

- Mechanical Property Balance

- Dynamic Stiffness: -3.4%.

- Static Stiffness: +6.9%.

- Stiffness Ratio: -10.1%.

- Commercial Applications and Value Proposition

Non-Pneumatic Tire Advancements

RT88 enables three transformative benefits:

- Service Life Extension: 300% fatigue life improvement.

- Safety Enhancement: Superior thermal stability and reduced heat buildup.

- Ride Quality Optimization: Idealized stiffness-damping balance.

Expanded Market Applications

- Electric Vehicle Tires: Mitigates high-torque thermal challenges.

- Advanced Suspension Components: Enhances dynamic performance stability.

- Extreme Environment Seals: Extends service life in demanding conditions.

Economic Justification

While adding modest material cost (1.5 phr), RT88 delivers:

- 15-20% production yield improvement.

- 30-40% reduction in warranty claims.

- Enhanced brand premium potential.

Technical Support Framework

Our comprehensive support includes:

- Formulation Optimization: Application-specific dosage calibration.

- Process Engineering: Vulcanization parameter optimization.

- Performance Validation: Comparative testing protocols.

- Troubleshooting: Production issue resolution.

Conclusion: Redefining Rubber Performance Standards

RT88, a product of top-tier Rubber additive Factory and Special Rubber chemical Manufacturers, establishes a new benchmark in crosslinking technology. Its demonstrated capabilities in non-pneumatic tire applications—including 3X fatigue life extension, exceptional thermal resilience, and optimized mechanical balance—position it as an essential technology for next-generation rubber engineering.

As mobility technologies evolve toward electrification and smart systems, RT88’s ability to simultaneously enhance multiple performance vectors makes it indispensable for manufacturers seeking competitive advantage in advanced rubber applications.

We invite industry partners, including Special Rubber chemical Suppliers, Rubber Heat Resistance and Crosslinking Agent Manufacturers, and Rubber Heat Resistance and Crosslinking Agent Suppliers, to collaborate in exploring RT88’s full potential across diverse applications and market segments. In addition to RT88, we offer a full range of specialty additives to continuously create value for our customers. Beyond RT88, we offer a complete range of specialty additives to continuously create value for our customers. Explore our full product portfolio here (PDF)

More detail please visit www.sanezenrubber.com .