Abstract: Driven by global “Dual Carbon” goals, the tire industry is undergoing a profound green revolution. Conventional tire manufacturing heavily relies on carbon black and silica derived from fossil fuels, whose energy-intensive, high-carbon emission production processes represent a major bottleneck for green transformation. Concurrently, major global markets including the European Union, China, and the United States have introduced increasingly stringent regulations and labeling systems, demanding higher performance in tire low rolling resistance, wet grip, and full lifecycle carbon footprint. This article delves into how SaneZen Group, a leading Bio Based Functional Modifier Manufacturer, leverages its LC Series bio based tire filler based on modified nano-lignin and nano-cellulose. Through its unique multi-level structural design, it not only successfully solves the tire performance “impossible trinity” but also provides a reliable technological pathway for the tire industry to achieve carbon neutrality from the material source. This innovative green tire filler is redefining the standards for manufacturing high-performance, sustainable tires.

I. Introduction: The Tire Industry’s “Impossible Trinity” Under Global Policy Pressure and Material Innovation

Tire design has long been constrained by the classic “impossible trinity”: the difficulty of simultaneously optimizing rolling resistance, wet grip, and wear resistance. The industry urgently needs high-efficiency tire rolling resistance reducer and tire wet grip improver to break through these bottlenecks. Reducing low rolling resistance saves fuel but often compromises safety-critical wet grip; improving wear resistance can increase rolling resistance, reducing energy efficiency.

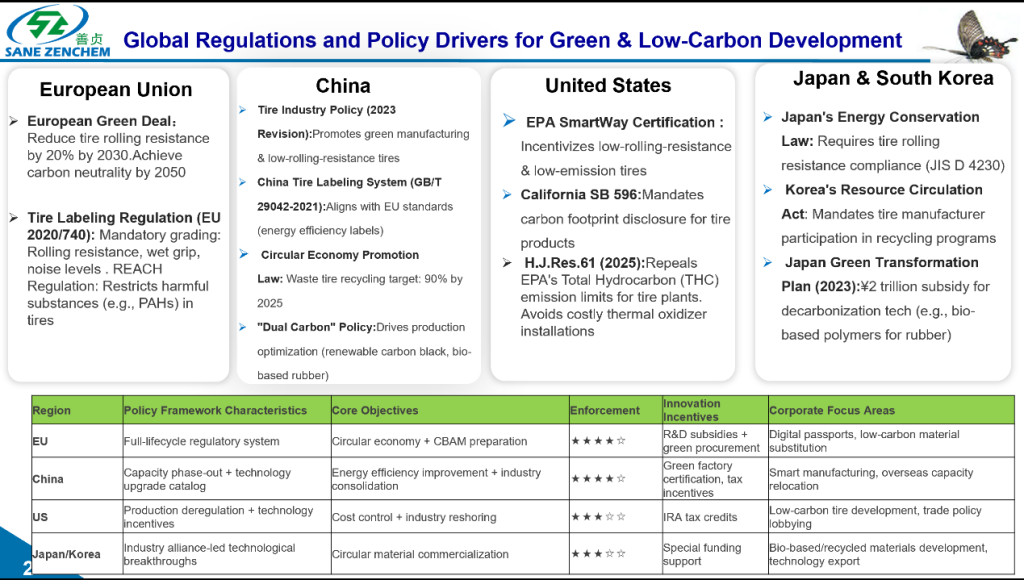

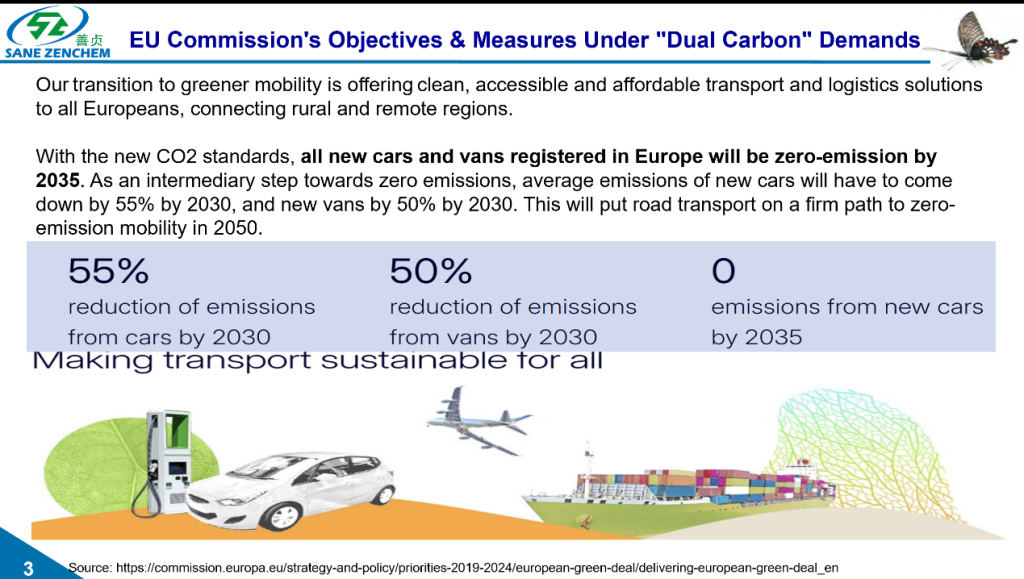

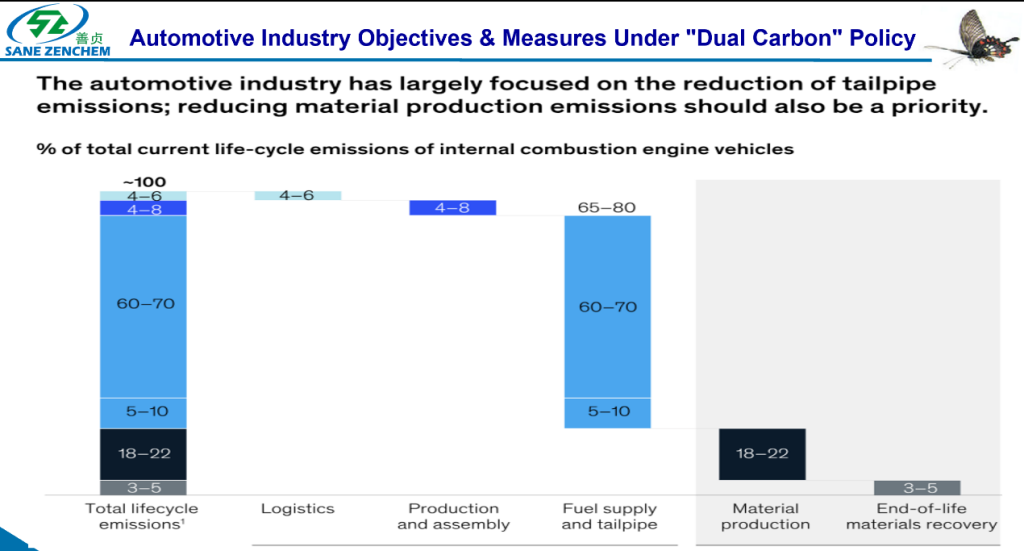

However, the current drivers of industry transformation extend far beyond technology itself. The global wave of carbon neutrality is reshaping the industrial landscape with unprecedented force:

- The European Green Deal requires a 20% reduction in tire rolling resistance by 2030 and aims for carbon neutrality by 2050.

- China’s “Dual Carbon” Policy and the “Tire Industry Policy (2023 Revision)” explicitly promote green manufacturing and the development of low rolling resistance tires.

- Regulations like California SB 596 in the US mandate the disclosure of the carbon footprint of tire products.

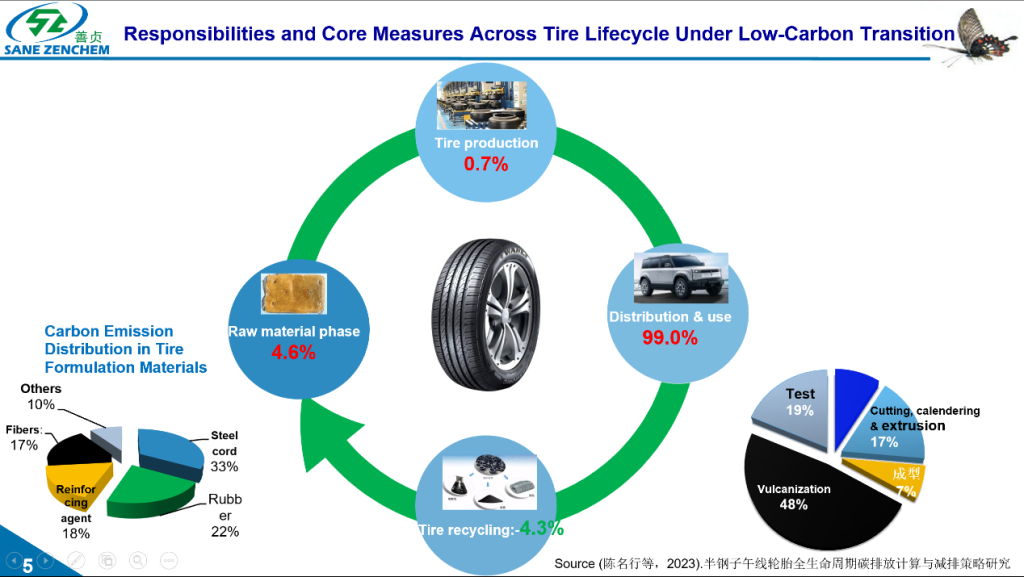

Data indicates that the use phase contributes to 99% of a tire’s total lifecycle carbon emissions. Therefore, the market urgently demands a revolutionary tire wear resistance filler capable of breaking both the performance bottleneck and the environmental barrier. SaneZen Group, a professional Rubber Functional filler Manufacturers China, has introduced the LC Series Bio Based Functional Modifier as a cutting-edge solution born from this context.

II. The LC Series: Green Innovation Sourced from Nature, Engineered by Science

The core of the LC Series is 100% plant-derived modified nano-lignin and nano-cellulose, constituting a new generation of high-performance bio based tire reinforcing filler. This is not merely biomass filling but the result of sophisticated materials engineering. Its technological core lies in its “Multi-level Structural Design”:

- Nano-sizing: Processing lignin and cellulose to the nanoscale, dramatically increasing specific surface area and reactivity.

- Functionalization: Introducing numerous active functional groups (e.g., phenolic hydroxyls) via chemical modification to profoundly enhance interaction with the rubber matrix.

- Supramolecular Assembly: Utilizing intermolecular forces to construct a stable three-dimensional network structure, creating synergistic reinforcement effects within the rubber compound.

This ingenious design allows its natural porous structure and active functional groups to effectively serve as a bio based filler replace carbon black, achieving lightweighting of the compound while maintaining or even enhancing mechanical strength, directly contributing to reduce tire rolling resistance.

III. Performance Breakthrough: Data-Driven Optimization of the “Magic Triangle”

Theory requires data validation. The following experimental data illustrates how the LC Series, as an efficient tire rolling resistance reducer and tire wet grip improver, reshapes the tire performance landscape.

1. Dynamic Performance Leap: Achieving Low Rolling Resistance and High Wet Grip

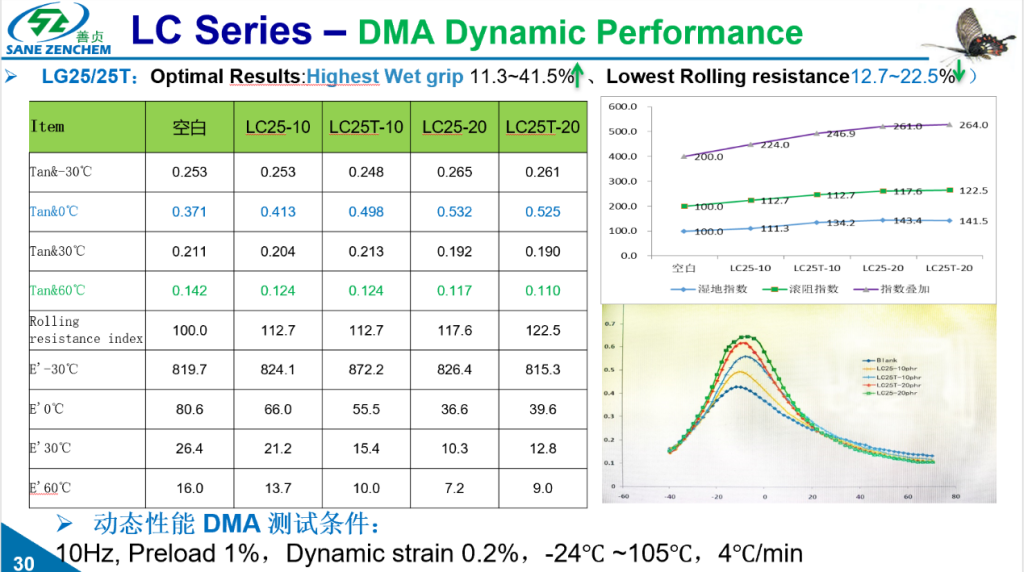

Dynamic Mechanical Analysis (DMA) is key for evaluating tire rolling resistance and wet grip. According to DMA test data (Conditions: 10Hz, Preload 1%, -24℃~105℃):

- Enhanced Wet Grip: The Tanδ value at 0°C correlates positively with wet grip. Data shows that after adding LC25/LC25T, Tanδ@0°C increased from 0.371 (blank) to a maximum of 0.532 (LC25-20 formulation), an improvement of 41.5%. This clearly demonstrates its powerful capability as a filler to improve tire wet grip.

- Significantly Reduced Rolling Resistance: The Tanδ value at 60°C correlates positively with rolling resistance. Data shows the LC Series can reduce it from 0.142 (blank) to a minimum of 0.110 (LC25T-20 formulation), a reduction of 22.5%. This proves it is also an exceptional filler to reduce tire rolling resistance.

This means the LC Series successfully achieves the “win-win” of substantially improved wet grip and significantly reduced rolling resistance, masterfully resolving the core conflict within the “magic triangle.”

2. Synergistic Gains in Durability and Lightweighting

- Improved Wear Resistance: The Lambourn abrasion test indicates that LC25/LC25T can reduce abrasion loss by up to 11.9%. This verifies its significant effect as a bio based filler enhance wear resistance. Concurrently, its lower specific gravity (reduced from 1.28 to 1.26) means a lighter tire for the same volume, achieving lightweighting.

- Superior Aging Resistance: After hot air aging tests (100°C×48h), LC formulations exhibit exceptional durability. Taking tear strength as an example, the blank formulation’s tear strength retention dropped sharply, whereas the LC25-20 formulation showed a greatly improved retention rate. This is due to the phenolic hydroxyl groups in lignin effectively scavenging free radicals generated during thermal, oxidative, and dynamic fatigue processes, interrupting oxidation chain reactions.

IV. Technical Synergy and Industrial Supply: The Comprehensive Advantage of SaneZen Group

SaneZen Group’s low-carbon technology solution is a systematic project. The LC Series can create synergistic effects with the group’s other innovative products, providing customers with comprehensive green solutions. Simultaneously, as a reliable Rubber Functional filler Suppliers China, we ensure stable and efficient product supply.

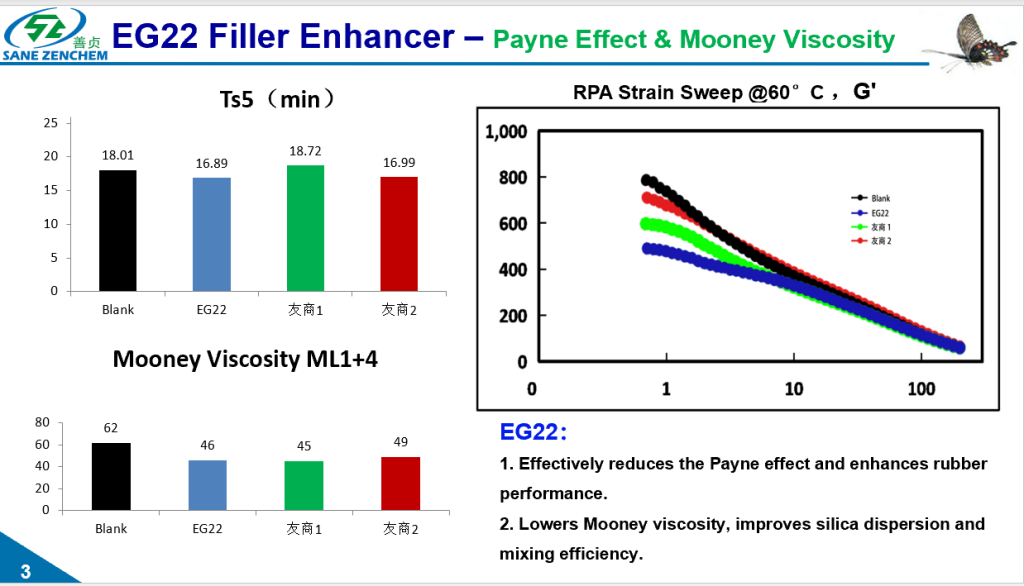

1. Synergy with the EG22 Filler Enhancer

EG22, as a bio-based filler enhancer, promotes the silanization reaction, significantly improves silica dispersion, and reduces the Payne effect and Mooney viscosity.

Using the LC Series and EG22 together in a formulation can achieve a “1+1>2” effect: EG22 creates a better dispersion environment and processing foundation for the LC Series, which in turn contributes its dynamic performance advantages and lightweighting characteristics.

2. Stable Supply Chain and Manufacturing Support

As a domestic Lignin filler for tires Manufacturers and Bio Based Functional Modifier Suppliers, SaneZen Group operates an advanced lignin filler for tires factory in Anhui, ensuring seamless transition from R&D to mass production and providing global customers with a stable, high-quality supply of bio based tire filler. We are not just Rubber Functional filler Manufacturers, but also partners providing customized solutions.

V. From Lab to Line: Performance Validation, Carbon Footprint, and ESG Value

Moving Towards Industrialization Based on Rigorous Experimental Data

The performance advantages of the LC Series have been fully validated in controlled laboratory environments, laying a solid foundation for its large-scale industrial application. Its performance improvement range fully meets and even exceeds the demands of the current high-end tire market.

Typical Application Scenario Simulation

Taking a typical passenger car tire formulation as an example, incorporating the LC Series Bio Based Functional Modifier to partially replace traditional fillers can achieve:

- Significant Performance Optimization: Easily achieve over 12% reduction in rolling resistance and over 18% improvement in wet grip, perfectly meeting the highest grade requirements of EU tire labeling regulations.

- Tangible Lightweighting Benefits: Compound density can be reduced by approximately 3-5%, which not only reduces raw material usage but also contributes extra to reducing vehicle energy consumption through its lightweighting effect.

Carbon Footprint Assessment and Sustainable Development Value

Based on Life Cycle Assessment methodology, compared to traditional silica/carbon black fillers, the LC Series Bio Based Functional Modifier exhibits tremendous environmental potential, estimated to achieve a 30%-50% reduction in carbon footprint. This is largely due to its ability to bio based filler replace carbon black.

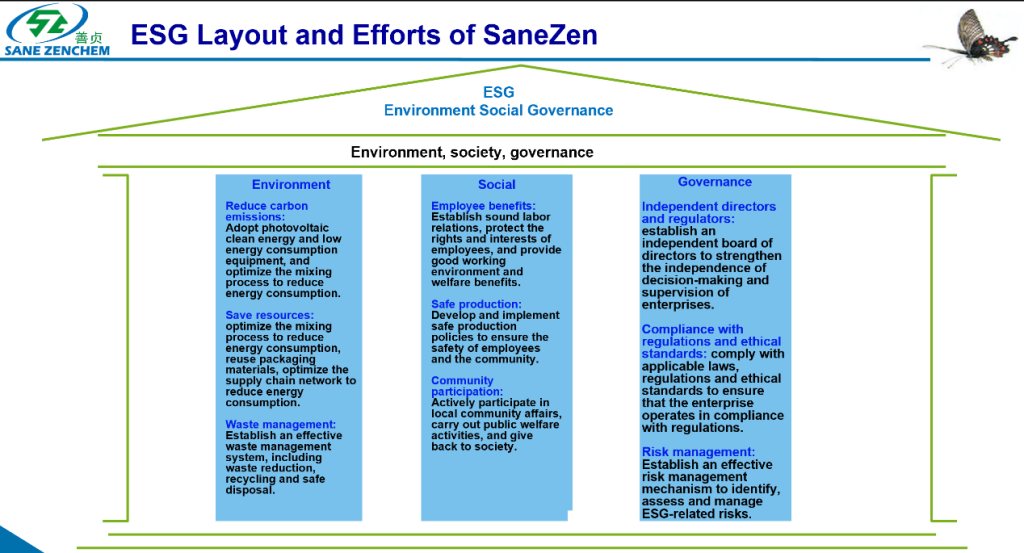

SaneZen Group ESG Layout and Efforts

These pages systematically explain SaneZen’s commitments and actions in environment, social, and governance, providing strong corporate endorsement for the LC Series’ environmental claims.

This stems primarily from:

- Renewable Feedstock: Plants absorb CO₂ during growth, creating a natural carbon sink.

- Cleaner Production Process: Its manufacturing process is significantly less energy-intensive compared to high-energy carbon black production.

- Use-Phase Energy Savings: By reducing tire rolling resistance, it saves fuel for the vehicle throughout its lifecycle, reducing exhaust emissions.

SaneZen Group’s comprehensive ESG layout ensures that the entire chain, from raw material procurement and manufacturing to product application, complies with the highest environmental and ethical standards, making the LC Series not only a product of technological innovation but also an embodiment of responsible corporate citizenship.

VI. Conclusion and Outlook

The advent of the LC Series Bio Based Functional Modifier marks a new era in tire material science. It is no longer merely an “eco-friendly alternative” but an advanced engineering material capable of comprehensively enhancing tire performance. Through its innovative nanotechnology and multi-level structural design, it successfully:

- Solves the “Impossible Trinity” of performance, balancing high wet grip, low rolling resistance, and high wear resistance.

- Addresses the Epochal Demand for Carbon Neutrality, reducing carbon emissions across the entire chain from raw materials and production to use.

- Aligns with Global Policy Directives, helping tire manufacturers easily comply with green regulations in the EU, China, North America, and elsewhere.

For tire manufacturers committed to leading the global green transition, embracing innovative bio based fillers like SaneZen Group’s LC Series is no longer an option, but a necessity. As a leading Bio Based Functional Modifier Manufacturers and Suppliers in China, SaneZen Group, with its strong R&D capabilities, comprehensive Rubber Functional filler product matrix, and profound commitment to sustainable development, is becoming an indispensable partner for the tire industry on its path to a carbon-neutral future.